ABB 57160001-KX DSDO 131 is a dedicated digital output unit for AC 800M series distributed control systems (DCS). Its core function is to convert the digital control instructions of the control system into industrial grade strong electrical signals, driving external actuators (such as contactors, solenoid valves, indicator lights) to operate. It is widely used in large-scale industrial scenarios such as power, petrochemicals, metallurgy, etc. that require strict reliability and safety of output signals (such as boiler control in power plants and chemical reactor interlock systems).

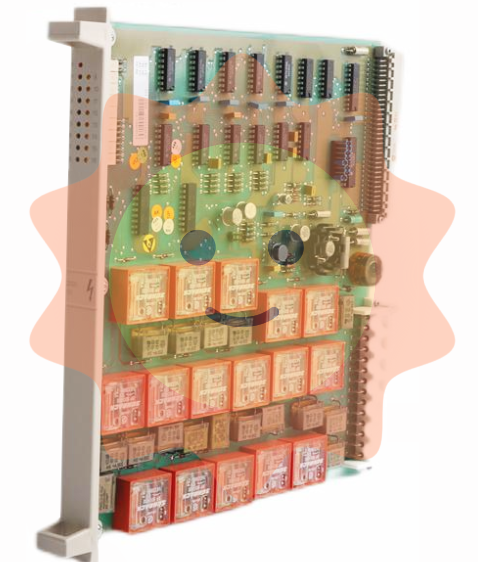

ABB 57160001-KX DSDO 131 Digital Output Unit

General Information

Product ID:57160001-KX

ABB Type Designation:DSDO 131

Catalog Description:DSDO 131 Digital Output Unit

Long Description:

DSDO 131 Digital Output Unit 16Ch.

0-240V AC/DC,relay,

Max load DC:48W, AC:720VA

Additional Information

Medium Description:Digital Output Unit

Product Type:Control_System_Accessory

Technical Information:

DSDO 131 Digital Output Unit 16Ch.

0-240V AC/DC,relay,

Max load DC:48W, AC:720VA

Ordering

HS Code:

853890 -- ELECTRICAL MACHINERY AND EQUIPMENT AND PARTS THEREOF; SOUND RECORDERS AND REPRODUCERS, TELEVISION IMAGE AND SOUND RECORDERS AND REPRODUCERS, AND PARTS AND ACCESSORIES OF SUCH ARTICLES; Parts suitable for use solely or principally with the apparatus of heading|8535, 8536|or 8537; Other

Customs Tariff Number:85389091

Dimensions

Product Net Depth / Length:324 mm

Product Net Height:18 mm

Product Net Width:225 mm

Product Net Weight:0.7 kg

Environmental

WEEE Category:5. Small Equipment (No External Dimension More Than 50 cm)

Number of Batteries:0

Product positioning and core values

ABB 57160001-KX DSDO 131 is a dedicated digital output unit for AC 800M series distributed control systems (DCS). Its core function is to convert the digital control instructions of the control system into industrial grade strong electrical signals, driving external actuators (such as contactors, solenoid valves, indicator lights) to operate. It is widely used in large-scale industrial scenarios such as power, petrochemicals, metallurgy, etc. that require strict reliability and safety of output signals (such as boiler control in power plants and chemical reactor interlock systems).

Its core value is reflected in "high safety output+strong load capacity+redundant fault tolerance": each output channel has independent overload and short-circuit protection, meeting industrial safety control requirements (compliant with SIL 2 safety level); Support high load driving (maximum single load of 5A), compatible with high-power actuators; Configurable hardware redundancy to avoid system downtime caused by single point failures and ensure continuous production.

Core parameters and functional characteristics

1. Key electrical and performance parameters

Output channel configuration

16 independent digital output (DO), supporting multiple voltage levels of 24V DC/110V DC/230V AC (specified when ordering, default 24V DC), output type is relay contact (single pole double throw, SPDT)

Load capacity

Single maximum load current 5A (resistive load), 2A (inductive load), contact switching voltage ≤ 250V AC/30V DC, mechanical life ≥ 10 million times, electrical life ≥ 100000 times (under rated load)

Protection function

Each channel is equipped with overload protection (overcurrent threshold 6A, self recovery), short-circuit protection (output cut off when short-circuit current ≥ 10A), and surge suppression (built-in RC absorption circuit to suppress inductive load power-off surge)

Response performance

Output switching time ≤ 10ms (from command issuance to contact action), isolation voltage between channels ≥ 2500V AC (1 minute), to avoid signal interference between channels

Communication and power supply

Support PROFIBUS DP communication protocol (communication rate 9.6kbps-12Mbps adaptive), communicate with AC 800M controller (such as PM861K01) through DP bus; Auxiliary power supply 24V DC (input range 19-30V DC), power consumption ≤ 15W

Environmental adaptability

Working temperature -25 ℃ to 70 ℃, relative humidity 5% -95% (no condensation), protection level IP20 (unit body), anti vibration performance 5-150Hz, 0.1g (sine wave vibration), anti impact performance 10g (11ms, half sine wave)

Security certification

Compliant with CE (EN 61010-1), UL (UL 508), SIL 2 (IEC 61508) safety standards, flame retardant rating UL 94 V-0

2. Core functional features

Multi voltage compatibility and flexible configuration: Supports 24V DC (suitable for small solenoid valves), 110V DC (industrial motor contactors), 230V AC (high-power indicator lights) multi voltage output, specified through "voltage coding" when ordering (such as "-24DC" indicating 24V DC output), and can adapt to actuators of different voltage levels without changing units, reducing spare parts inventory costs.

Independent channel protection and diagnosis: Each output channel has independent overcurrent and short-circuit protection. When a certain channel triggers protection due to a load short circuit, only the output of that channel is cut off, and other channels work normally (fault isolation); The status of each channel (normal/overload/short circuit) can be read in real time through the PROFIBUS DP bus, and fault information is automatically uploaded to the controller for remote troubleshooting (such as locating the short circuit solenoid valve circuit).

Redundancy and Fault Tolerant Design: Supports "1+1" hardware redundancy configuration (requiring 2 identical units to be connected in parallel), with redundant logic configured through ABB Control Builder M software. When the main unit fails, the backup unit automatically switches within ≤ 100ms, with uninterrupted output signals, suitable for critical control circuits that cannot be stopped (such as emergency shutdown control of power plant steam turbines).

Anti interference and surge suppression: The output circuit is equipped with an RC absorption circuit and a varistor, which can suppress the surge voltage of over 2000V generated by inductive loads (such as motor contactor coils) when they are powered off, protecting the contacts from being burned out by arcs; 2500V AC isolation design between channels to avoid electromagnetic interference to other channels during the operation of high-power actuators.

Adaptation devices and collaborative applications

1. Core adaptation equipment

Controller

ABB AC 800M series controllers (such as PM861K01, PM864K01) achieve command issuance and status feedback through PROFIBUS DP bus (using ABB FCProfibus cable, model 3FLA000100R0001)

Terminal unit

ABB DSTF610 terminal unit (using TK520 cable to transfer low-power sensor signals, and cooperating with DSDO 131 to achieve a complete control link of "controller → DSDO 131 → actuator"), ABB TU515 terminal unit (suitable for simple scenarios)

External actuator

24V DC solenoid valve (such as ABB V230 series), 110V DC motor contactor (such as ABB AX100 series), 230V AC indicator light (such as ABB CL series), 24V DC relay (such as ABB CR-M series)

Auxiliary equipment

ABB PROFIBUS DP bus connector (model 3RK1901-1BB00), redundant power module (such as PM861K01-R, providing dual power backup for the unit), surge protector (such as ABB OVR series, used for outdoor actuator lightning protection)

2. Collaborative Application Case with 3HAC4776-1/1 Module and DSTF610: Control of Large Chemical Reactor

System architecture: The reaction kettle needs to implement a "temperature over limit → emergency stop" chain control, involving 3 temperature sensors (AI signal, connected to AC 800M controller), 2 mixing motor contactors (110V DC, required to be driven by DSDO 131), 3 feed valve solenoid valves (24V DC, required to be driven by DSDO 131), and 1 emergency stop button (DI signal, connected to 3HAC4776-1/1 module).

Connection logic:

The 3HAC4776-1/1 module transmits the emergency stop signal to the AC 800M controller through the RS485 serial port; The temperature sensor signal is connected to the AI interface of the controller after being transferred through the DSTF610 terminal unit;

When the controller determines that "temperature exceeds the limit" or "emergency stop triggered", it sends a "load cut-off" command to DSDO 131 through the PROFIBUS DP bus;

Channel 1-2 (110V DC output) of DSDO 131 cuts off the power supply of the mixing motor contactor, channel 3-5 (24V DC output) closes the solenoid valve of the feeding valve, and channel 6 outputs an alarm signal (driving the 230V AC alarm light).

Core advantage: The independent channel protection of DSDO 131 avoids the overall shutdown caused by a short circuit of a certain solenoid valve; Redundant configuration ensures that in the event of communication interruption between the controller and the unit, the backup unit can still execute emergency shutdown instructions, in compliance with SIL 2 safety requirements in the chemical industry.

Installation process and key points

Cabinet fixing: Installed through 35mm DIN rails, with a distance of ≥ 15cm from the AC 800M controller and ≥ 30cm from high-power equipment (such as frequency converters) to avoid electromagnetic interference; If redundant units are configured, two units need to be installed side by side with a distance of ≥ 5cm to ensure heat dissipation.

Power connection: Use 2.5mm ² copper wire to connect the "+24V" and "GND" terminals of the redundant power module (PM861K01-R) to the unit power input terminals ("V+" and "V -"). Reversing the positive and negative poles will trigger internal protection (the unit is not damaged and needs to be reconnected to the correct polarity).

Communication and output wiring:

Connect the "DP IN" and "DP OUT" terminals of the unit to the DP interface of the controller using a PROFIBUS DP bus cable, and connect a 120 Ω terminal resistor to the bus terminal (only installed at the end unit of the bus);

The actuator wire is connected to the output terminal of the unit ("NO", "COM", "NC", choose normally open/normally closed contacts according to requirements), with a single wire cross-sectional area of ≤ 2.5mm ². High power actuators (such as 5A contactors) need to be separately equipped with fuses (10A/250V).

Redundant configuration: The PROFIBUS DP addresses of two units need to be set to be different (set through the dip switch on the side of the unit, such as setting the main unit to 1 and the backup unit to 2). Enable the "DP redundancy" function in the Control Builder M software and configure the fault switching logic.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-