ABB DSBB175 is a professional expansion module designed specifically for industrial PLC system function expansion, belonging to the ABB AC 800M series PLC supporting product line. Its core function is to expand the digital input and output points of the PLC, solving the problem of insufficient control points in industrial sites and the need for flexible expansion. This module has the core advantages of "high compatibility", "plug and play", and "stable and reliable". It can seamlessly integrate with ABB AC 800M series PLCs (such as PM861, PM864), expand control channels without complex configuration, and adapt to dynamic changes in control point requirements in industries such as petrochemicals, power energy, metallurgy, and high-end manufacturing. It is a key component for industrial PLC systems to achieve "on-demand expansion and flexible upgrading".

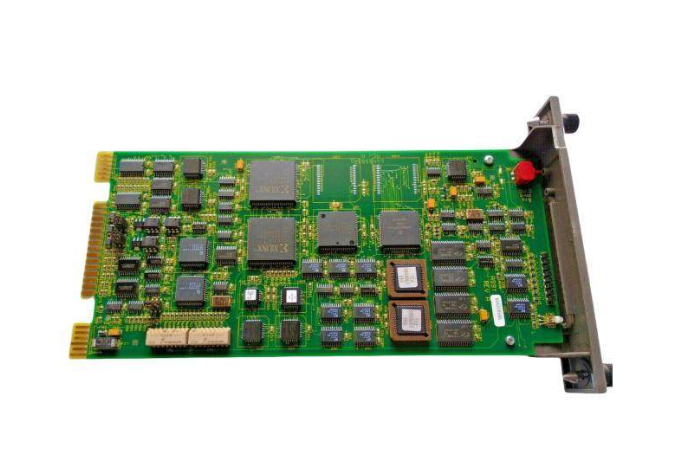

ABB DSBB175 Industrial PLC Expansion Module

Product Overview

ABB DSBB175 is a professional expansion module designed specifically for industrial PLC system function expansion, belonging to the ABB AC 800M series PLC supporting product line. Its core function is to expand the digital input and output points of the PLC, solving the problem of insufficient control points in industrial sites and the need for flexible expansion. This module has the core advantages of "high compatibility", "plug and play", and "stable and reliable". It can seamlessly integrate with ABB AC 800M series PLCs (such as PM861, PM864), expand control channels without complex configuration, and adapt to dynamic changes in control point requirements in industries such as petrochemicals, power energy, metallurgy, and high-end manufacturing. It is a key component for industrial PLC systems to achieve "on-demand expansion and flexible upgrading".

Compared to independent control modules, its uniqueness lies in its deep integration into the ABB PLC ecosystem, allowing for direct reuse of PLC power, communication bus, and control logic without the need for additional driver programming. This significantly reduces the complexity and cost of system expansion, while ensuring control consistency and real-time performance of the expanded system.

Specification parameters

Core extension parameters (digital extension core indicators):

Expansion type: Digital mixed input/output expansion module, supporting 16 digital inputs and 16 digital outputs. A single module can add 32 control channels to meet the point expansion needs of small and medium-sized PLC systems;

Input signal characteristics: Digital input supports DC 24V voltage signal, compatible with PNP/NPN bipolar sensors, input response time ≤ 1ms (can be configured as 0.1ms/1ms/10ms through software), input current ≤ 5mA/channel, overload current tolerance ≤ 100mA (continuous for 1 second);

Output signal characteristics: The digital output adopts relay output type, with a maximum load current of 2A (AC 250V/DC 30V) per output, supports normally open contact output, output action time ≤ 10ms, and has short-circuit protection (trigger contact protection when overload current>5A);

Isolation design: 2500V AC electrical isolation is used between the input circuit and the output circuit, and 500V AC isolation is used between the input circuit and the PLC backplane bus, effectively avoiding external interference from entering the PLC core system.

Compatibility and Communication Parameters (PLC Ecological Adaptation):

Compatible with PLC models: Designed specifically for ABB AC 800M series PLCs, compatible with mainstream CPU modules such as PM860, PM861, PM864, PM865, etc. Data exchange is achieved through the PLC backplane bus (Profinet IRT bus) without the need for additional communication cables;

Communication speed: The communication speed of the backplane bus is consistent with that of the PLC CPU, up to 1Gbps, with a data update cycle of ≤ 1ms, ensuring real-time data synchronization between the expansion module and the PLC core without control delay;

Configuration compatibility: Supports parameter configuration (such as input response time and output fault threshold) through ABB Control Builder M software (V6.0 and above versions), with a unified configuration interface with PLC CPU, without the need to learn new operating logic.

Physical and environmental parameters (industrial scenario adaptation):

Physical specifications: Dimensions 100mm x 160mm x 40mm (length x width x height), with an industrial grade aluminum alloy shell (surface anodized treatment, corrosion-resistant), weighing approximately 0.5kg; supports stacking installation with AC 800M series PLC standard guide rails, with module spacing ≥ 10mm, suitable for compact layout of PLC control cabinets;

Environmental adaptability: The working temperature is -25 ℃~60 ℃, and it can operate stably in harsh environments such as low-temperature workshops and high-temperature control rooms; Storage temperature -40 ℃~85 ℃, meeting long-term inventory needs; Relative humidity 5%~95% (no condensation), protection level IP20 (to be installed in a closed PLC control cabinet); Anti interference meets the IEC 61000-6-3 industrial standard and can resist electrostatic discharge (8kV contact discharge), radio frequency radiation (10V/m field strength), and fast transient pulse group (2kV) interference.

Performance characteristics

High compatibility and plug and play: As an exclusive expansion module for the ABB AC 800M series, there is no need to install additional drivers. After connecting the module to the PLC CPU through the backplane bus, the PLC can automatically recognize the module model and expansion channel (recognition time ≤ 2s). Simply activate the expansion channel in the Control Builder M software to use it, greatly reducing the debugging time for system expansion and adapting to the "fast upgrade" needs of industrial sites.

Stable real-time data exchange: Relying on the PLC backplane Profinet IRT bus, the data transmission rate between the expansion module and the PLC CPU reaches 1Gbps, with a data update cycle of ≤ 1ms. It can achieve a full process real-time response of "PLC issuing control instructions → expansion module execution → status feedback to PLC", without data delay, and is suitable for scenarios with high real-time control requirements (such as equipment linkage in metallurgical production lines).

Multi level electrical isolation and protection: The input and output circuits adopt 2500V AC high-strength isolation, which can effectively block the grounding circulation and electromagnetic interference (such as the interference generated by the start stop of the frequency converter) in the industrial field, and avoid the impact of expansion module faults on the PLC core system; The output circuit is equipped with relay contact protection (which cuts off the output when the overload current is greater than 5A) to prevent module burnout caused by short circuits in the executing components. It also supports output fault diagnosis (such as contact adhesion detection) to improve system reliability.

Flexible parameter configuration and diagnosis: Supports configuring input response time (0.1ms/1ms/10ms) through Control Builder M software, which can be flexibly adjusted according to sensor types (such as high-speed photoelectric sensors requiring 0.1ms response, ordinary limit switches requiring 10ms response), balancing response speed and anti-interference ability; The module has built-in fault diagnosis function, which can monitor the status of input and output circuits in real time (such as input open circuit, output short circuit), and upload fault information (such as "DO1 short circuit") to the PLC and upper computer for quick problem location.

Compact design and high integration: A single module integrates 16 inputs and 16 outputs, with a volume only half of traditional independent modules. It supports stacking and installation with PLC CPUs and other expansion modules (such as analog expansion modules and safety modules), greatly saving control cabinet space; The module terminal adopts a spring type quick wiring design, which shortens the wiring time by 60% compared to screw terminals, and the wiring is firm, avoiding terminal loosening caused by vibration.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-