ABB CR-M4LS is a compact industrial control module that focuses on logic control and signal conditioning for small and medium-sized industrial equipment. It belongs to ABB's basic automation control product line and its core function is to achieve the acquisition, logical operation, and execution control of digital/analog signals in industrial fields, while also possessing lightweight system integration characteristics. This module has the core advantages of "high cost-effectiveness", "easy installation and debugging", and "stable and reliable". It can connect sensors, actuators, and upper control systems (such as PLC, HMI) to solve the automation control needs of small and medium-sized production lines and single machine equipment. It is suitable for fields such as food processing, textile machinery, HVAC, and small machine tools that require moderate control complexity. It is a practical control component that simplifies industrial control architecture and reduces system integration costs.

ABB CR-M4LS Industrial Control Module

Product Overview

ABB CR-M4LS is a compact industrial control module that focuses on logic control and signal conditioning for small and medium-sized industrial equipment. It belongs to ABB's basic automation control product line and its core function is to achieve the acquisition, logical operation, and execution control of digital/analog signals in industrial fields, while also possessing lightweight system integration characteristics. This module has the core advantages of "high cost-effectiveness", "easy installation and debugging", and "stable and reliable". It can connect sensors, actuators, and upper control systems (such as PLC, HMI) to solve the automation control needs of small and medium-sized production lines and single machine equipment. It is suitable for fields such as food processing, textile machinery, HVAC, and small machine tools that require moderate control complexity. It is a practical control component that simplifies industrial control architecture and reduces system integration costs.

Compared to high-end control modules, its advantages lie in its compact size, easy wiring, and the ability to implement basic control logic (such as start stop interlocking and timing control) without complex programming. At the same time, it has industrial grade anti-interference and protection capabilities, which can adapt to most indoor industrial environments and provide a cost-effective solution for the automation upgrade of small and medium-sized enterprises.

Specification parameters

Electrical parameters (control core indicators):

Power supply voltage: DC 24V ± 10%, suitable for conventional voltage fluctuations in industrial scenarios, typical working current of 0.4A~0.8A, maximum power consumption ≤ 20W, low-power design suitable for long-term continuous operation;

Input signals: 8 digital inputs (DC 24V, PNP/NPN bipolar compatible, response time ≤ 1ms), 4 analog inputs (0~10V or 4~20mA optional, accuracy ± 0.1%), capable of collecting signals from limit switches, photoelectric sensors, temperature and humidity sensors and other devices;

Output signal: 6-channel digital output (DC 24V, maximum load current 2A/channel, built-in short-circuit protection), 2-channel analog output (0~10V or 4~20mA optional, linearity ± 0.2%), can drive relays, small contactors, solenoid valves, frequency converters and other actuating components;

Control Logic: Supports basic logic operations (AND/OR/NOT, Delay, Interlock), with 16 built-in programmable logic blocks and a program capacity of 32KB. It supports configuring control parameters through upper computer software or panel buttons.

Communication and Expansion Parameters (Lightweight Requirement Adaptation):

Communication interface: Integrated with one RS485 serial communication interface, compatible with Modbus RTU protocol, communication speed up to 115200bps, supporting data exchange with upper PLC, touch screen or industrial computer, meeting the remote monitoring needs of small and medium-sized systems;

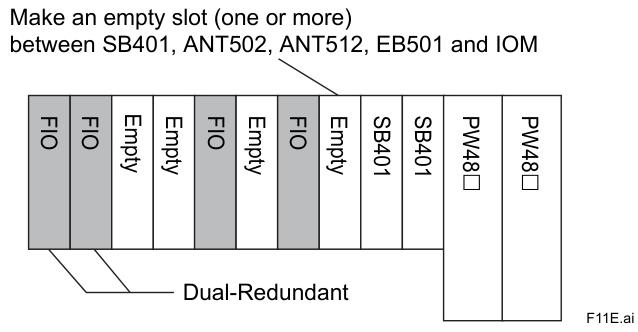

Expansion capability: Reserve 1 expansion slot, compatible with ABB dedicated digital expansion modules (such as CR-EX-D8 8-channel digital input module), can be expanded up to 16 channels of digital input/output, suitable for scenarios where the number of control points is slightly expanded.

Physical and environmental parameters (industrial scenario adaptation):

Physical specifications: Dimensions 140mm x 90mm x 35mm (length x width x height), with a flame-retardant plastic shell (flame retardant grade UL94 V-0), weighing approximately 0.3kg; supports 35mm DIN standard rail installation, with installation hole spacing of 120mm, suitable for mainstream small control cabinet layouts;

Environmental adaptability: Operating temperature range of -10 ℃~55 ℃, suitable for indoor industrial environments such as workshops and computer rooms; Storage temperature -40 ℃~85 ℃, meeting long-term inventory needs; Relative humidity of 10%~90% (no condensation), protection level IP20 (to be installed in a closed control cabinet to resist dust intrusion); Anti interference complies with the IEC 61000-6-2 industrial standard and can resist general electromagnetic interference (such as motor start stop interference and radio frequency interference).

Performance characteristics

Concise and easy-to-use logic control: No professional programming knowledge is required, supporting control logic settings through ABB's official simple configuration software (such as ABB Easy Control 2.0) or module panel buttons (such as "Input 1 and Input 2 trigger simultaneously → Output 1 action" and "Input 3 triggers with a delay of 5 seconds → Output 2 action"). The graphical configuration interface is intuitive and easy to understand, and debugging time can be reduced by more than 50%, suitable for the operational needs of technical personnel in small and medium-sized enterprises.

Stable signal processing capability: The digital input adopts a photoelectric isolation design (isolation voltage 2000V AC), effectively avoiding external interference signals from entering the module, ensuring accurate acquisition of switch signals; The analog input is equipped with an RC filtering circuit, which can filter out high-frequency noise (such as electromagnetic interference generated by a frequency converter), and the acquisition accuracy is controlled within ± 0.1%. It is suitable for stable monitoring of continuous signals such as temperature and pressure.

Basic security protection mechanism: integrates multiple protection functions - power supply overvoltage protection (triggered to cut off when the voltage exceeds 28V), to avoid module damage due to voltage fluctuations; Short circuit protection for digital output (immediately shuts off when the output current exceeds 2.5A/circuit) to prevent module burnout caused by short circuit of execution components; Internal over temperature protection of the module (triggering derating operation when the temperature exceeds 70 ℃) ensures long-term operational reliability.

Lightweight system integration: compact size, clear layout of wiring terminals (input/output/power/communication terminal partition arrangement), support for quick plug-in wiring (some terminals are optional), high installation and wiring efficiency; The communication protocol is simple and universal (Modbus RTU), which can be integrated with mainstream upper level devices (such as ABB AC500 PLC and Weilun Tong touch screen) without complex configuration. The system integration cost is reduced by 30% to 40% compared to traditional PLC control solutions.

High cost performance and long life: industrial components (such as high-temperature resistant capacitors and anti-aging terminals) are used, with MTBF ≥ 60000 hours, reducing the cost of later maintenance; The unit price of the module is lower than that of high-end control modules, and it supports functional expansion. It can be gradually upgraded according to control needs (such as adding expansion modules directly when increasing input points in the later stage), balancing cost and flexibility.

Working principle

The ABB CR-M4LS industrial control module is based on the basic closed-loop control architecture of "signal acquisition logic judgment instruction output state feedback". The core process is as follows:

Signal acquisition and preprocessing:

Digital signal: Receive switch signals from limit switches, buttons, photoelectric sensors and other devices through input terminals (such as "material in place" and "safety door closed"), isolate interference through photoelectric isolation circuits, convert them into binary digital signals (0/1) recognizable by the module, and transmit them to the internal logic processing unit;

Analog signal: Receive continuous signals from temperature and humidity sensors, pressure sensors, and other devices (such as "25 ℃ temperature" and "0.5MPa pressure"), filter out noise through an RC filtering circuit, convert them into digital signals through a 16 bit ADC (analog-to-digital converter), and then convert them into actual physical quantities through a scaling algorithm (such as "4-20mA current signal" corresponding to "0-100 ℃ temperature value"), and store them in a data register.

Logical judgment and instruction generation:

The logic processing unit performs real-time judgment on the collected input signals based on the user's preset control logic (such as "interlock relationship" and "delay parameter" configured through software). For example, when the "start button signal (input 1=1)" and the "safety door closing signal (input 2=1)" meet the same conditions, it generates a control instruction for "driving motor operation (output 1=1)"; If the analog input detects "temperature>50 ℃ (input 5=10V)", generate the command to "start the cooling fan (output 3=1)".

Instruction output and execution driver:

Digital output: After the control command is amplified by the output driving circuit, it outputs a DC 24V voltage through the terminal to drive the relay, solenoid valve and other executing components to act (such as controlling the motor to start after the relay is closed); Real time monitoring of current in the output circuit. If a short circuit occurs (current>2.5A), immediately cut off the output to protect the module and actuator components;

Analog output: If the instruction is continuous adjustment (such as "adjusting the frequency of the frequency converter to 30Hz"), a 16 bit DAC (digital to analog converter) will convert the digital instruction into an analog signal (such as "12mA current signal" corresponding to "30Hz frequency"), and output it to the frequency converter, proportional valve and other devices to achieve continuous parameter adjustment.

Status feedback and monitoring:

The module real-time collects its own working status (such as power supply voltage, output signal status, internal temperature), and visually displays it through panel indicator lights: the power light (PWR) is always on to indicate normal power supply, the input lights (DI1~DI8) are lit to indicate that the corresponding input signal is valid, the output lights (DO1~DO6) are lit to indicate corresponding output action, and the fault light (ERR) is lit to indicate module abnormality; At the same time, the status data is uploaded to the upper computer through the RS485 interface, making it easier for operators to remotely monitor the system's operating status.

Precautions

Installation and wiring specifications:

Before installation, it is necessary to confirm that the module model (CR-M4LS) matches the system control requirements (such as input and output points, communication protocol). It is strictly prohibited to connect AC power or DC voltage beyond the rated range (such as 36V DC); The installation location should be far away from strong magnetic field equipment (such as high-power transformers, frequency converters) and heating equipment (such as power resistors), with a distance of ≥ 80mm from the above equipment to avoid high temperature or magnetic field interference affecting signal processing;

When wiring, it is necessary to strictly distinguish the terminal functions: the power terminal (+24V/GND) must not be reversed, the input terminals (DI1~DI8) can only be connected to DC 24V signals, and the output terminals (DO1~DO6) cannot directly drive high-power equipment (such as motors above 3kW, which need to be switched through contactors); The RS485 communication terminals (A/B/GND) need to distinguish between positive and negative poles, with A connected to the upper computer RS485-A and B connected to the upper computer RS485-B to avoid communication abnormalities.

Configure and debug security:

Before configuring control logic, it is necessary to clarify the device action logic (such as "which input signals trigger which output actions" and "whether delay is required") to avoid logical conflicts (such as the same output being repeatedly triggered by multiple conditions); When using configuration software, it is necessary to first backup the default configuration. If the configuration is incorrect, the initial state can be restored;

During debugging, perform a no-load test first: disconnect the power supply of the executing component, connect only the module and sensor, simulate input signals (such as manually triggering limit switches), and observe whether the output indicator lights turn on/off according to the preset logic; After the no-load test shows no problems, gradually connect the execution components and start testing from low load (such as driving the indicator light first, then driving the relay and contactor) to avoid logical errors that may cause equipment misoperation (such as accidental motor start-up).

Maintenance and troubleshooting:

Regular maintenance: Clean the surface dust of the module every 3 months (wipe with a dry soft cloth, do not use wet cloth or cleaning agent), check whether the wiring terminals are loose (gently pull the wire with your hand, no obvious displacement is recommended), test whether the input and output signals are normal (measure the input terminal voltage and output terminal on/off with a multimeter);

Fault handling: When a fault occurs, first check the status of the panel indicator light: if the PWR light is not on, check the power supply voltage and wiring; If the ERR light is on, read the fault code through the upper computer (such as "E01" representing output short circuit, "E02" representing communication interruption), and correspondingly investigate the output circuit or communication line; If a module needs to be replaced, it is necessary to ensure that the new module model is consistent with the original module, reconfigure the control logic, conduct a no-load test, and then connect it to the system.

Environmental adaptation requirements:

The module is not suitable for environments with high dust, corrosive gases (such as hydrogen sulfide, chlorine gas), or condensation. If installation is required in these environments, the control cabinet must be equipped with a dust cover, dehumidification device, or anti-corrosion coating;

If there are frequent voltage fluctuations in the system (such as peak power consumption in the factory), it is recommended to install a DC stabilized power supply (output 24V DC, ripple ≤ 10mV) at the module power input terminal to avoid voltage fluctuations causing module restart or control logic disorder.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-