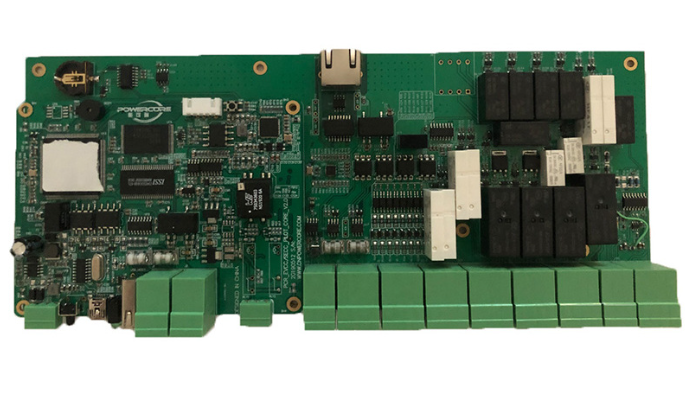

TOSHIBA HC422B 7862 System Module

Product Introduction: The TOSHIBA HC422B (also referenced as module 7862) is a key electronic control module within Toshiba's industrial automation portfolio. It is part of a component family that may include units like the 2N3B2895-C5, N-300, and 2J3B2895-C2. This module is engineered to perform dedicated high-level control, signal processing, or system communication tasks, serving as a vital component in complex drive and automation solutions.

Product Overview and Component Family

The TOSHIBA HC422B represents a critical piece of system intelligence within larger industrial equipment. Referred to by its base code HC422B or the numeric identifier 7862, this module is typically not a standalone product but is designed for integration into Toshiba's sophisticated drive systems, programmable controllers, or specialized industrial computers. Its function is often central to the operation of the host system, potentially managing core control algorithms, coordinating communication between subsystems, or processing critical feedback signals.

Associated Component References

This module is commonly specified and used alongside related components, forming a functional subsystem. These associated part numbers provide context for its application:

2N3B2895-C5 / 2J3B2895-C2: These likely represent complementary control boards, interface cards, or firmware-specific variants within the same hardware family, possibly differing in memory, processing speed, or supported features.

N-300: This may refer to a specific system series, a chassis model, or a higher-level control unit into which the HC422B module is installed, defining its operational platform and connectivity.

Understanding this ecosystem is key to identifying the correct module for system maintenance, repair, or upgrade.

Core Technical Features and System Role

Centralized Control & Processing

Acting as a system nerve center, the HC422B module likely houses a powerful microprocessor or digital signal processor (DSP). It is responsible for executing complex real-time control loops, mathematical computations for drive control (like vector control), and logic sequences. This offloads demanding tasks from other system components, ensuring high performance and deterministic response times essential for precise motion and process control.

Advanced System Communication Gateway

A primary function is to manage internal and external data flow. The module serves as a communication hub, interfacing with the system's power stage, operator interfaces, and higher-level networks (such as industrial Ethernet or fieldbus systems). It handles protocol conversion, data logging, and ensures synchronized operation across all connected parts of the automation system.

Comprehensive Diagnostics and Protection

Engineered for reliability, the module incorporates extensive diagnostic routines. It continuously monitors system health parameters—including voltage levels, current draw, temperature, and signal integrity. By preemptively identifying anomalies or faults, it can trigger protective shutdowns, alert operators, and store event logs, which are invaluable for troubleshooting and preventive maintenance, thereby maximizing system uptime.

Representative Technical Specifications

The specifications for a system-level module like the HC422B are defined by its role within the host platform (e.g., a Toshiba VF-S11/VF-S15 drive or a TOSLINE controller).

Feature Category General SpecificationModule Designation HC422B / 7862 (System Control/Interface Module)

Associated Components 2N3B2895-C5, N-300 unit, 2J3B2895-C2

Primary Function Main system control, signal processing, or communication management

Host System Compatibility Toshiba industrial AC drives, multi-axis controllers, or automation systems

Key Interfaces High-speed internal data bus, dedicated I/O ports, network communication links

Monitoring & Protection Real-time diagnostics for overcurrent, overvoltage, overheating, and communication faults

Operating Environment Rated for standard industrial ambient conditions (temperature, humidity, vibration)

Primary Industrial Applications

As a core control module, the HC422B enables advanced automation in performance-critical applications across various sectors.

High-Performance AC Drive Systems: Serving as the main control board in Toshiba variable frequency drives for precise control of motors in centrifugal pumps, fans, and complex machinery.

Multi-Axis Motion Control: Acting as the central processor in systems coordinating the synchronized movement of multiple servo or stepper motors in robotics, CNC machines, or packaging lines.

Industrial Process Control: Integrating into supervisory control units for continuous processes in chemical, pharmaceutical, or food & beverage production, managing loops and sequencing.

Material Handling & Logistics: Controlling the speed and torque of conveyor systems, sortation units, and automated storage/retrieval systems (AS/RS).

Test and Simulation Equipment: Providing the computational power and precise I/O handling needed for dynamic test rigs and industrial simulators.

Integration and Operational Value

The integration of the HC422B module elevates the capability of the host system. Its specialized processing power allows for the implementation of advanced control strategies that improve energy efficiency, product quality, and equipment responsiveness. The module's diagnostic capabilities facilitate a shift from reactive to predictive maintenance, reducing unplanned downtime. Furthermore, its role as a communication backbone ensures seamless integration with plant-wide monitoring and control systems (SCADA/MES), enabling data-driven decision-making and operational optimization.

Conclusion

The TOSHIBA HC422B (7862) module, alongside its related components like the 2N3B2895-C5, is a testament to the layered complexity and engineering depth in modern industrial automation. It provides the essential intelligence that transforms basic hardware into a smart, efficient, and reliable control system. For system integrators and maintenance engineers, this module represents a critical point of focus for ensuring system performance, facilitating upgrades, and executing precise repairs, thereby supporting the relentless drive for productivity and quality in industry.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-