The GE IS200TTURH1CCC S1DF00Z Terminal Turbine Board (hereinafter referred to as the "TTURH1CCC Board") is the core terminal interface unit in the General Electric (GE) Speedtronic Mark VIe turbine control system, designed specifically for turbine operation status monitoring, signal aggregation, and control command distribution. This board serves as a key hub between the on-site sensors, actuators, and main control system of the steam turbine, undertaking important tasks such as core parameter acquisition, control signal relay, and equipment status feedback. It is widely used in steam turbine control scenarios in thermal power, nuclear power, industrial drive, and other fields, providing solid hardware support for safe start stop, stable operation, and fault warning of the turbine.

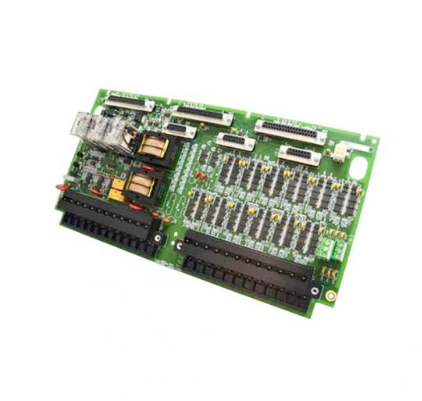

GE IS200TTURH1CCC S1DF00Z Terminal Turbine Plate

Product Overview

The GE IS200TTURH1CCC S1DF00Z Terminal Turbine Board (hereinafter referred to as the "TTURH1CCC Board") is the core terminal interface unit in the General Electric (GE) Speedtronic Mark VIe turbine control system, designed specifically for turbine operation status monitoring, signal aggregation, and control command distribution. This board serves as a key hub between the on-site sensors, actuators, and main control system of the steam turbine, undertaking important tasks such as core parameter acquisition, control signal relay, and equipment status feedback. It is widely used in steam turbine control scenarios in thermal power, nuclear power, industrial drive, and other fields, providing solid hardware support for safe start stop, stable operation, and fault warning of the turbine.

It adopts industrial grade reinforced design, with high anti-interference, wide temperature adaptability, and high reliability. It can work stably in complex environments such as high temperature, vibration, electromagnetic interference, etc. in the operation site of the steam turbine. It is the core component of the GE Mark VIe control system to achieve closed-loop control and safety protection of the steam turbine.

Core functions and roles

2.1 Signal aggregation and distribution function

The core function of TTURH1CCC board is to achieve centralized signal management of steam turbine control system and build a communication bridge between on-site equipment and main controller, including:

-Multi type signal collection and aggregation: Centralize the collection of core parameter signals for steam turbine operation, including turbine speed signals (from speed sensors), shaft vibration and displacement signals (from eddy current sensors), bearing temperature signals (from thermal resistors/thermocouples), steam pressure and temperature signals (from pressure/temperature transmitters), etc. The board uniformly receives and preliminarily conditions these analog, digital, and frequency signals, laying the foundation for subsequent transmission to the main controller.

-Accurate distribution of control instructions: Receive turbine control instructions issued by the main controller, such as speed control valve opening adjustment instructions, extraction valve control instructions, emergency stop instructions, etc., convert the instruction signals into signal types that can be recognized by on-site actuators (such as 4-20mA analog signals or digital switch signals), and accurately distribute them to corresponding actuators (such as servo valves, solenoid valves) to achieve real-time control of the operating status of the turbine.

2.2 Signal conditioning and safety protection functions

-Signal preprocessing and optimization: Built in signal filtering, amplification, and linearization processing circuits are used to reduce noise, adjust gain, and correct errors in the collected on-site signals, effectively eliminate interference signals, improve the accuracy and stability of signal transmission, and ensure that the parameters obtained by the main controller can truly reflect the operating status of the steam turbine.

-Safety interlock protection: Integrating signal logic processing modules related to steam turbine safety protection. When the collected parameters exceed the safety threshold (such as speed exceeding the limit, shaft vibration exceeding the limit, and bearing temperature being too high), the local interlock response can be quickly triggered, such as directly outputting an emergency stop signal to the actuator and feedback alarm information to the main controller, providing dual safety protection for the steam turbine and avoiding malignant accidents.

-Electrical isolation protection: using photoelectric isolation and power isolation technology, the on-site input and output signals are electrically isolated from the internal circuits of the board, and between the board and the main controller. The isolation voltage can reach 2500Vrms or more, effectively blocking the influence of electromagnetic interference and common mode voltage on the system, while preventing the backflow of on-site fault signals that damage the main controller, and improving the overall safety of the system.

2.3 Status monitoring and fault feedback function

-Real time monitoring of equipment status: Real time monitoring of the working status of the board itself (such as power supply voltage, circuit integrity, communication link status) and the working status of connected on-site equipment, identifying signal abnormalities, line disconnections, sensor failures, and other issues through built-in diagnostic circuits.

-Quick feedback of fault information: When a fault is detected, the board sends a fault code and fault type information to the main controller through a dedicated communication channel, and displays the fault status (such as power failure, signal loss, communication interruption) intuitively through the board indicator light, making it easy for operation and maintenance personnel to quickly locate the fault point and shorten the troubleshooting time.

2.4 System adaptation and expansion functions

As a dedicated terminal board for the GE Mark VIe control system, the TTURH1CCC board has seamless compatibility with the main controller, communication module, power module, and other components within the system. It supports high-speed data exchange with the main controller through industrial buses such as ControlNet and EtherNet/IP, ensuring real-time signal transmission and meeting the strict response speed requirements of steam turbine control. At the same time, the board reserves standardized expansion interfaces that can be connected to additional sensors or actuators according to actual control requirements, enhancing the flexibility of system configuration.

Key technical parameters

Power parameters

Working power supply: 24V DC ± 10%; Backup power supply: 24V DC redundant input

Support dual power redundancy, improve power supply reliability, and avoid board shutdown caused by single power failure

Input channel

Analog input: 8-12 channels

Supports 4-20mA, 0-10V DC signals, compatible with temperature, pressure and other transmitters

Frequency/speed input: 2-4 channels

Supports 0-10kHz frequency signals, compatible with magneto electric/photoelectric speed sensors

Digital input: 16-24 channels

Optical isolation, compatible with NPN/PNP, compatible with limit switches and status feedback signals

output channel

Analog output: 4-6 channels

Output 4-20mA or 0-10V DC signal for controlling servo valves and regulating valves

Digital output: 8-12 channels

Relay output/open collector output, maximum load current 2A, used for controlling solenoid valves and alarm devices

Isolation level

Isolation between input/output/power supply: 2500Vrms (1 minute)

Compliant with IEC 61010-1 safety standard, strong anti-interference ability

working environment

Temperature: -10 ℃ -70 ℃; Humidity: 5% -95% (no condensation)

Adapt to the harsh environment of high temperature and high humidity on the steam turbine site

communication interface

System bus: compatible with GE Mark VIe dedicated bus; Auxiliary interface: 1-channel RS485 (for local debugging)

Support high-speed communication with the main controller and local parameter configuration

Dimensions

3U standard rack mounted, dimensions: 100mm x 320mm x 160mm (height x width x depth)

Compatible with GE Mark VIe standard control cabinet, easy to install

Applicable scenarios and application areas

The TTURH1CCC board, with its powerful signal processing capabilities, high reliability, and safety protection features, is mainly used in fields that require extremely high precision and safety for steam turbine control. Typical scenarios include:

1. Control of thermal power generation steam turbines: Used in coal-fired and gas-fired power generation units for controlling steam turbines of different capacities such as 300MW, 600MW, and 1000MW. It collects signals such as turbine speed, shaft vibration, and main steam parameters to achieve speed regulation, load control, and emergency shutdown protection of the steam turbine, ensuring stable power generation of the power generation unit.

2. Nuclear power auxiliary turbine control: In nuclear power plants, it is used to control auxiliary equipment such as feedwater pump turbines and circulating water pump turbines, collect equipment operating parameters, issue control instructions, ensure stable operation of auxiliary systems, and provide support for the safety of nuclear power units.

3. Industrial driven turbine control: In the petrochemical, chemical, steel and other industrial fields, industrial turbine control is used to drive compressors, fans, pumps and other equipment. By accurately adjusting the turbine speed, it meets the dynamic load requirements of industrial production and improves production efficiency.

4. Steam turbine test bench: Used for parameter acquisition and control of the test bench during the development, manufacturing, and maintenance of steam turbines, real-time monitoring of the operating status of the turbine under different working conditions, and providing data support for equipment performance optimization and fault diagnosis.

Installation and usage precautions

5.1 Installation specifications

-The board needs to be installed in a dedicated cabinet for the GE Mark VIe control system, which should have good ventilation, heat dissipation, and dust prevention functions; The installation location should be far away from the high-temperature area of the steam turbine body (such as near the steam pipeline), and it is recommended to maintain a distance of more than 1 meter from the heat source. At the same time, avoid installing in areas with severe vibration, and install shock absorbers if necessary.

-Before wiring, it is necessary to confirm that the power supply of the board is turned off, strictly follow the pin definition of the board and the official GE wiring diagram for wiring, distinguish between analog, digital, power, and communication interfaces, and strictly prohibit misconnection or mixing; Key signal cables such as speed and vibration should use twisted pair shielded wires, with the shielding layer grounded at one end (grounding resistance ≤ 4 Ω) to reduce electromagnetic interference.

-The board power supply needs to use redundant power supply to ensure that when one power supply fails, the other can seamlessly switch to ensure the continuous operation of the board; The power wiring should be firm to avoid power failure or abnormal operation of the board due to poor contact.

5.2 Key points of use and maintenance

-Before the system is put into operation, the engineer station of GE Mark VIe control system needs to perform parameter configuration and functional testing on the board, including signal acquisition accuracy calibration, control command output testing, fault diagnosis function verification, etc., to confirm that all performance indicators of the board meet the requirements before it can be put into use.

-During operation, it is necessary to regularly monitor the working status of the board, including indicator light status, power supply voltage, signal transmission stability, etc; Regularly clean the dust inside the board and cabinet, check if the wiring terminals are loose, ensure good heat dissipation of the board, and avoid faults caused by dust accumulation or poor contact.

-When the board malfunctions, the fault code should be checked through the main controller first to preliminarily determine the cause of the fault; Before troubleshooting, it is necessary to cut off the power supply and related signal circuits of the board, and it is strictly prohibited to plug or unplug the board or connect it with power on; When replacing the board, it is necessary to use products of the same model and specifications. After replacement, parameter configuration and calibration need to be carried out again to ensure compatibility with the system.

-The maintenance and overhaul of the board must be carried out by professional technicians with GE Mark VIe control system operation qualifications. Non professionals are strictly prohibited from operating it without authorization. During the maintenance process, safety protection measures must be taken to avoid electric shock or equipment damage accidents.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-