The GE IS200TSVCH1ADC S1CX01H servo input-output board (hereinafter referred to as the "TSVCH1ADC board") is the core servo interface component in the General Electric (GE) Speedtronic Mark VIe control system, designed specifically for signal interaction and control of industrial grade servo drive systems. This board serves as a bridge between the servo system and the main controller, undertaking key tasks such as input signal acquisition, output command transmission, signal isolation and amplification. It is widely used in high-precision industrial control scenarios such as gas turbines, steam turbines, and large motor control, providing reliable guarantees for the stable operation and precise control of equipment.

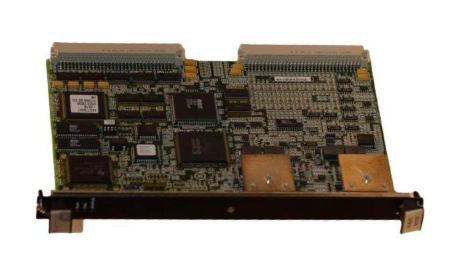

GE IS200TSVCH1ADC S1CX01H servo input-output board

Product Overview

The GE IS200TSVCH1ADC S1CX01H servo input-output board (hereinafter referred to as the "TSVCH1ADC board") is the core servo interface component in the General Electric (GE) Speedtronic Mark VIe control system, designed specifically for signal interaction and control of industrial grade servo drive systems. This board serves as a bridge between the servo system and the main controller, undertaking key tasks such as input signal acquisition, output command transmission, signal isolation and amplification. It is widely used in high-precision industrial control scenarios such as gas turbines, steam turbines, and large motor control, providing reliable guarantees for the stable operation and precise control of equipment.

Its design follows industrial grade high reliability standards, with characteristics such as anti electromagnetic interference, wide temperature operation, and anti vibration. It can adapt to complex and harsh industrial site environments and is an important component of the GE Mark VIe control system for achieving servo closed-loop control.

Core functions and roles

2.1 Core functions of signal interaction

The core function of the TSVCH1ADC board is to achieve bidirectional signal interaction between the servo system and the main controller, which includes the following two aspects:

-Input signal acquisition: Accurately collect feedback signals from servo motors, such as encoder signals (position, speed feedback), temperature sensor signals, current/voltage detection signals, etc. These analog or digital signals are preprocessed (such as filtering, isolation) and transmitted to the main controller to provide real-time data support for the controller's operation and decision-making.

-Output command execution: Receive servo control commands issued by the main controller, such as speed commands, position commands, torque commands, etc., amplify and convert the command signals into signal types recognizable by the servo drive through internal driving circuits, drive the servo motor to complete corresponding actions according to the commands, and achieve precise control of the motor's operating status.

2.2 Signal processing and protection functions

-Signal isolation: Using optoelectronic or magnetic isolation technology, the input and output signals are electrically isolated from the internal circuits of the board, effectively suppressing electromagnetic interference (EMI) and common mode interference in industrial sites, avoiding the impact of interference signals on control accuracy and board stability, and ensuring the accuracy of signal transmission.

-Overcurrent/Overvoltage Protection: Built in overcurrent and overvoltage detection and protection circuits. When abnormal overcurrent or overvoltage situations occur in the input and output signals, the board will quickly trigger protection mechanisms, such as cutting off signal paths or issuing alarm signals, to prevent damage to the board and connected servo equipment and improve system safety.

-Fault diagnosis: It has basic fault self diagnosis function, which can monitor the working status of the board itself in real time (such as power supply voltage, circuit on/off) and signal transmission status. When a fault occurs, it feeds back the fault code to the main controller through specific pins or communication interfaces, making it easy for operation and maintenance personnel to quickly locate and troubleshoot the problem.

2.3 System adaptation function

As a dedicated board for the GE Mark VIe control system, the TSVCH1ADC board has good compatibility with other components within the system, such as the main controller, communication module, and power module. It supports high-speed communication with the main controller through system buses (such as ControlNet, EtherNet/IP), ensuring real-time transmission of control instructions and feedback signals, and meeting the high requirements of servo systems for control response speed. At the same time, its standardized interface design facilitates the installation, replacement, and maintenance of the board, reducing system operation and maintenance costs.

Key technical parameters

Power parameters

Input voltage: ± 5V DC/± 15V DC

Typical working power supply, supporting a wide voltage fluctuation range (± 10%)

Input channel

Analog input: 4-8 channels

Supports 0-10V DC or 4-20mA signals, compatible with sensor feedback

Digital input: 8-16 channels

Optical isolation, compatible with NPN/PNP, compatible with encoder and limit switch signals

output channel

Analog output: 2-4 channels

Output range 0-10V DC or 4-20mA, used for issuing control commands

Digital output: 4-8 channels

Open collector output, maximum load current 1A, used for controlling signal output

Isolation level

Input/output isolation: 2500Vrms (1 minute)

Compliant with IEC 61010-1 safety standard

working environment

Temperature: 0-60 ℃; Humidity: 10% -90% (no condensation)

Adapt to wide temperature and high humidity environments in industrial sites

communication interface

System bus interface: compatible with GE Mark VIe bus

Support high-speed data exchange with the main controller

Dimensions

Standard 3U rack mounted board, compatible with Mark VIe control cabinet

Compliant with industrial board installation specifications

Applicable scenarios and application areas

The TSVCH1ADC board, with its high-precision signal processing capability and high reliability, is mainly used in industrial fields that require strict servo control. Typical scenarios include:

1. Power generation equipment control: The speed control system of gas turbines and steam turbines collects signals such as turbine speed and blade position, and issues precise control instructions to ensure stable operation of the unit; The variable pitch servo system of wind turbines achieves real-time adjustment of blade angles and improves power generation efficiency.

2. Industrial motor control: The starting, speed regulation, and braking control of large asynchronous motors and synchronous motors, such as steel rolling mill motors in steel plants and rotary kiln motors in cement plants, are achieved through precise closed-loop control of motor speed and torque through boards.

3. Precision manufacturing equipment: servo drive system for CNC machine tools and robot workstations, collecting feedback signals such as machine coordinate axis position and robot joint angle, issuing position control instructions to ensure machining accuracy and motion accuracy.

4. Heavy machinery control: Servo actuator control for cranes, metallurgical machinery, and mining machinery, such as speed control for crane lifting mechanisms and tilt angle control for metallurgical furnaces, to achieve safe and stable operation of equipment through boards.

Installation and usage precautions

5.1 Installation specifications

-The board needs to be installed in a dedicated rack for the GE Mark VIe control system to ensure a secure installation and avoid poor contact caused by vibration; Before installation, it is necessary to confirm that the rack is well grounded with a grounding resistance of ≤ 4 Ω to enhance anti-interference capability.

-When connecting input and output cables, it is necessary to strictly follow the pin definition of the board for wiring, distinguish between analog and digital interfaces, and avoid damage to the board due to incorrect connections; The cable should use shielded wire, with the shielding layer grounded at one end to reduce interference.

-The power supply of the board must be matched with the system power supply, and it is strictly prohibited to connect voltage beyond the rated range; When wiring the power supply, it is necessary to distinguish between positive and negative poles to avoid reversing and burning the internal circuit of the board.

5.2 Key points of use and maintenance

-Before starting the system, it is necessary to perform initialization testing on the board through the main controller to confirm that the board is in normal working condition and that no fault signals have been triggered before it can be put into operation.

-During operation, it is necessary to regularly monitor the working temperature, power supply voltage, and signal transmission status of the board to avoid long-term operation in high temperature and high load environments and extend its service life.

-When the board malfunctions, the power supply of the board should be cut off first before troubleshooting; When replacing the board, it is necessary to choose a product of the same model and specification. After replacement, it is necessary to reset the configuration to ensure compatibility with the system.

-The maintenance of the board should be carried out by professional technicians, and non professionals are strictly prohibited from disassembling or modifying the board without authorization to avoid safety accidents or equipment damage.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-