ABB UFC092BE01 is an industrial grade high-density binary input (DI) module, belonging to the ABB AC 800M series distributed control system signal acquisition unit. Its core function is to convert digital switch signals (such as buttons, travel switches, sensor status signals) from industrial sites into system recognizable digital signals, which are transmitted to controllers or control boards for logical operations. It is widely used in scenarios that require a large amount of digital signal acquisition, such as power, petrochemical, metallurgy, intelligent manufacturing, etc. (such as production line equipment status monitoring, large-scale unit interlock protection signal acquisition).

ABB UFC092BE01 Binary input module

Product positioning and core values

ABB UFC092BE01 is an industrial grade high-density binary input (DI) module, belonging to the ABB AC 800M series distributed control system signal acquisition unit. Its core function is to convert digital switch signals (such as buttons, travel switches, sensor status signals) from industrial sites into system recognizable digital signals, which are transmitted to controllers or control boards for logical operations. It is widely used in scenarios that require a large amount of digital signal acquisition, such as power, petrochemical, metallurgy, intelligent manufacturing, etc. (such as production line equipment status monitoring, large-scale unit interlock protection signal acquisition).

Its core value is reflected in "high-density acquisition+strong anti-interference+high reliability": a single module supports 16 binary inputs, greatly compressing the installation space of the cabinet; Adopting optoelectronic isolation and signal filtering technology to adapt to complex electromagnetic environments in industrial sites; Equipped with fault self diagnosis and channel level protection functions, ensuring signal acquisition without packet loss or misjudgment, and guaranteeing the stable operation of the control system.

Core parameters and functional characteristics

1. Key electrical and performance parameters

Input channel configuration

16 independent binary inputs (DI), supporting 24V DC drain input (compatible with source input, requiring external circuit configuration), input signal range 18-30V DC (high level effective)

Signal response performance

Channel response time ≤ 1ms (from signal triggering to module recognition), inter channel crosstalk ≤ 50 μ V, ensuring signal interference free when multiple channels are triggered simultaneously

Isolation and anti-interference

Each channel is optically isolated from the backplane bus, with an isolation voltage of 2500V AC (1 minute); Integrated RC filtering circuit for input circuit (adjustable filtering frequency of 100Hz), with anti electromagnetic interference level in accordance with EN 61000-6-2 standard

Diagnosis and status indication

Each channel is equipped with an independent LED indicator light (green constant light indicates effective signal, off indicates no signal); Module level fault indicator light (red constant light indicates power failure, flashing indicates communication failure)

Communication and power supply

Support PROFIBUS DP communication protocol (communication rate 9.6kbps-12Mbps adaptive), communicate with AC 800M controller or DAPC100 control board through DP bus; Auxiliary power supply 24V DC (input range 19-30V DC), power consumption ≤ 5W

Environmental adaptability

Working temperature -25 ℃ to 70 ℃, relative humidity 5% -95% (no condensation), protection level IP20 (module body), anti vibration performance 5-150Hz, 0.1g (sine wave vibration), anti impact performance 10g (11ms, half sine wave)

Security certification

Compliant with CE (EN 61010-1), UL (UL 508), SIL 2 (IEC 61508) safety standards, flame retardant rating UL 94 V-0

2. Core functional features

High density and flexible installation: The module size is only 45mm (width) x 100mm (height) x 120mm (depth), suitable for 35mm DIN rail installation. The 16 channel integration is 100% higher than the conventional 8-channel DI module. In scenarios with dense signal points (such as automotive assembly lines, which require monitoring the status of over 200 sensors), the number of modules used can be reduced by 50%, significantly reducing cabinet space.

Wide voltage compatibility and polarity protection: Supports 18-30V DC wide range input, compatible with different specifications of sensor power supplies in industrial sites (such as 24V DC switch power supplies, 27V DC equipment power supplies); The input circuit has polarity reversal protection, so even if the positive and negative poles are reversed, the module will not be damaged (only no signal output), reducing the risk of installation and wiring errors.

Channel level diagnosis and fault isolation: The status of each channel (normal/open/short) can be read in real time through the PROFIBUS DP bus. When a certain channel triggers an abnormality due to sensor failure (such as wire short circuit), the module only marks the fault of that channel and does not affect the signal acquisition of other channels; The fault information is automatically uploaded to the system monitoring station, making it easy for operation and maintenance personnel to quickly locate the fault point (such as a short circuited sensor circuit).

Anti interference and signal stability: Each channel is designed with independent optoelectronic isolation, which can suppress common mode interference and differential mode interference generated by high-power equipment (such as frequency converters and motors) in industrial sites; The RC filtering circuit can filter high-frequency noise (such as signal jitter caused by electromagnetic radiation), ensuring that the signal acquisition accuracy still reaches 99.99% in complex electromagnetic environments (such as steel rolling workshops in steel mills).

Adaptation devices and collaborative applications

1. Core adaptation equipment

Controller/Control Board

ABB AC 800M controller (such as PM864K01), ABB DAPC100 3ASC25H203 control board, signal upload through PROFIBUS DP bus

Signal conversion unit

ABB DSTF610 terminal unit (using TK520 cable to transfer sensor signals for wiring management and signal preprocessing), ABB TU515 terminal unit (suitable for signal transfer in simple scenarios)

External sensors/switches

24V DC photoelectric sensor (such as ABB O5F series, NPN output, leakage signal), travel switch (such as ABB LS45 series, normally closed/normally open contacts), button switch (such as ABB M2SS series, 24V DC reset type)

Auxiliary equipment

ABB PROFIBUS DP bus connector (3RK1901-1BB00), redundant power module (PM861K01-R, providing dual power backup for the module), signal isolator (such as ABB AI801 Isolator, enhancing weak signal anti-interference capability)

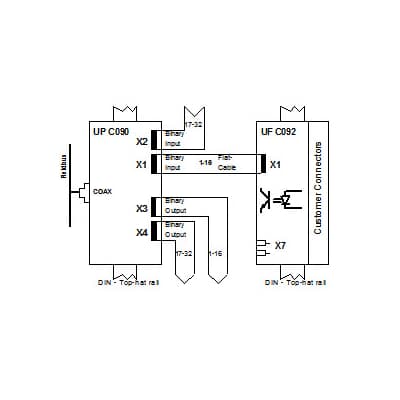

2. Collaborative application case with DAPC100 control board and DSTF610: Chain protection system for petrochemical reaction kettle

System architecture: The reactor needs to monitor 12 critical status signals (such as high pressure alarm, high temperature alarm, stirring motor operation status, and feed valve switch status). When any signal triggers an "abnormality", the system needs to immediately stop feeding and activate the emergency pressure relief valve, involving 16 DI signal acquisition (including 4 backup signals) and 2 DO control signal outputs.

Connection logic:

12 sensor/switch signals (pressure switch, temperature switch, motor status feedback) are connected to DI terminals 1-12 of DSTF610 terminal unit through wires. DSTF610 is connected to the input interface of UFC092BE01 module through TK520 cable to achieve signal preprocessing and isolation;

UFC092BE01 transmits the collected digital signals to the DAPC100 control board through the PROFIBUS DP bus, and the control board runs the interlock protection logic to determine whether the signal is abnormal;

When the "high pressure" or "high temperature" signal is detected, DAPC100 triggers the DSDO 131 digital output unit through the DO interface, cuts off the power supply of the feed valve (stops feeding) and opens the pressure relief valve (emergency pressure relief), while outputting an alarm signal to the monitoring station.

Core advantage: UFC092BE01's 16 channels meet the system signal acquisition requirements (including backup channels to enhance redundancy); The photoelectric isolation and filtering function ensures that there is no interference or false alarm in the strong electromagnetic environment of the chemical workshop; The channel level diagnostic function can quickly locate faulty sensors (such as a short circuit in a temperature switch), reducing the troubleshooting time to within 10 minutes.

Installation and troubleshooting specifications

1. Installation process and key points

Rail fixation: Installed through a 35mm DIN rail, with a distance of ≥ 8mm between adjacent modules (such as DAPC100 control board, DSDO 131 unit) to ensure heat dissipation; The module needs to be installed inside the control cabinet (away from the cabinet door to avoid dust and moisture). If there are strong interfering devices such as frequency converters inside the control cabinet, the distance between the module and the module should be ≥ 30cm.

Power connection: Use a 1.5mm ² copper wire to connect the "+24V" and "GND" terminals of the redundant power module (PM861K01-R) to the module power input terminals ("V+" and "V -"). Reversing the positive and negative poles will trigger internal protection (the module is not damaged and needs to be reconnected to the correct polarity to resume operation).

Signal and communication wiring:

Input signal: The output terminal of DSTF610 terminal unit is connected to the DI terminals ("DI1" to "DI16") of UFC092BE01 through a 1.0mm ² shielded twisted pair cable. The shielding layer is grounded at one end (module side), and the signal transmission distance is ≤ 200m (signal repeater needs to be added for over distance);

Communication bus: Use PROFIBUS DP cable to connect the "DP IN" and "DP OUT" terminals of the module to the DP interface of the controller/control board. The module at the end of the bus needs to be connected to a 120 Ω terminal resistor (enabled by the module side dip switch).

Address setting: Use the 8-bit dip switch on the side of the module to set the PROFIBUS DP address (range 1-126), ensuring that it does not overlap with other DP slave addresses in the system (if set to 10, it needs to be configured accordingly in the Control Builder M software).

2. Common faults and solutions

Fault phenomenon

troubleshooting direction

No signal acquisition for all channels

Check if the auxiliary power supply voltage is within the range of 19-30V DC; Confirm if the PROFIBUS DP bus communication is normal (module "COM" light flashing indicates normal communication, constant off indicates communication interruption); If the power supply and communication are normal, it may be an internal motherboard fault of the module and needs to be replaced

Single channel without signal acquisition

Measure the input voltage of the channel with a multimeter (normally 24V DC, high level is valid); Check whether the sensor is normal (such as whether the photoelectric sensor is triggered and whether the output signal is normal); If the input voltage is normal but there is still no signal, it may be due to damage to the channel optoelectronic isolation chip, and the module needs to be replaced

Channel signal false alarm (frequent on-off)

Check if the input signal cable is laid in parallel with the power cable (such as 380V motor cable) (separate wiring is required, with a spacing of ≥ 20cm); Enable the RC filtering function of the module (set the filtering frequency to 50-100Hz through software) to filter high-frequency noise; Check for mechanical shaking of the sensor (such as poor contact of the travel switch contacts)

Communication bus interruption

Check if the A/B wires of the DP cable are reversed (module terminal "DP-A" is connected to bus "A" wire, "DP-B" is connected to bus "B" wire); Confirm whether the bus terminal resistor is installed correctly (only the terminal module is enabled); Use ABB DP diagnostic tool (such as 3RK1901-1BB00) to test the bus signal strength. If the signal attenuates, shorten the cable length or add a repeater

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-