ABB DAPC100 3ASC25H203 is an advanced control board dedicated to the field of large-scale industrial process control, belonging to the core computing unit of ABB Advant OCS/DCS system. Its core function is to achieve high-precision closed-loop control, multivariable coordinated control, and logical chain operation of complex industrial processes. It is widely used in scenarios such as power (coordinated control of thermal power units), petrochemicals (multi parameter adjustment of large reactors), metallurgy (tension control of steel rolling processes), etc., which require strict control algorithm complexity and real-time operation.

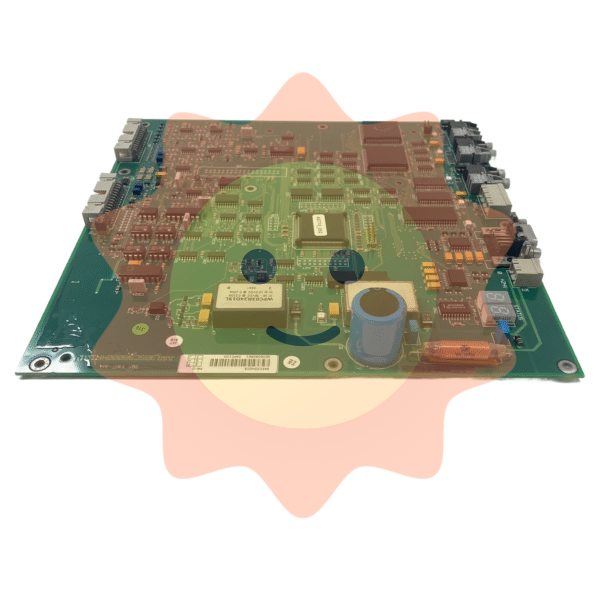

ABB DAPC100 3ASC25H203 Industrial Control Board

Product positioning and core values

ABB DAPC100 3ASC25H203 is an advanced control board dedicated to the field of large-scale industrial process control, belonging to the core computing unit of ABB Advant OCS/DCS system. Its core function is to achieve high-precision closed-loop control, multivariable coordinated control, and logical chain operation of complex industrial processes. It is widely used in scenarios such as power (coordinated control of thermal power units), petrochemicals (multi parameter adjustment of large reactors), metallurgy (tension control of steel rolling processes), etc., which require strict control algorithm complexity and real-time operation.

Its core value is reflected in "high computing algorithm support+strong process control capability+system level compatibility": equipped with a dedicated process control processor, supporting high-order control algorithms (such as predictive control and fuzzy control); Integrated multi-channel analog/digital processing interface, which can directly interface with sensors and actuators; Seamless compatibility with ABB Advant OCS/DCS systems and AC 800M expansion modules ensures the stability and scalability of large-scale control systems.

Core parameters and functional characteristics

1. Key electrical and performance parameters

Processor and computing power

32-bit dedicated process control processor, with a main frequency of 800MHz, integrated floating-point arithmetic unit (FPU), computing power ≥ 100 MIPS, supporting real-time multitasking scheduling (task switching time ≤ 1ms)

Signal processing interface

Analog input (AI): 8 channels, 4-20mA/0-10V dual range, sampling accuracy ± 0.05% (16 bit AD conversion); Analog output (AO): 4-channel, 4-20mA, output accuracy ± 0.1% (14 bit DA conversion); Digital input (DI): 16 channels, 24V DC (leakage type, response time ≤ 50 μ s); Digital output (DO): 8 channels, 24V DC (source type, single load ≤ 1A)

Control algorithm support

Built in PID/PID cascade control, feedforward control, ratio control, and split range control algorithms; Support user-defined algorithms (written in ABB Control Language); Up to 32 independent control circuits can be configured

Communication and Storage

Supports PROFIBUS DP (communication rate 9.6kbps-12Mbps) and MODBUS RTU communication protocols; Onboard 128MB Flash (program storage)+256MB DDR3 (data cache), supports data power failure storage (storage time ≥ 10 years)

Power and Environment

24V DC power supply (input range 19-30V DC), power consumption ≤ 12W, with overvoltage (32V DC protection), overcurrent (2A protection), and reverse connection protection; Working temperature -20 ℃ to 65 ℃, relative humidity 5% -95% (no condensation), protection level IP20 (onboard interface area), anti vibration performance 10-500Hz, 0.1g

Security certification

Compliant with CE (EN 61010-1), UL (UL 508), SIL 2 (IEC 61508) safety standards, flame retardant rating UL 94 V-0

2. Core functional features

High order process control capability: support predictive control algorithm (MPC), predict the change trend of process variables based on historical data and real-time parameters, and adjust control commands in advance. It is applicable to industrial processes with strong hysteresis (such as temperature control of large distillation tower). The control accuracy is improved by more than 30% compared with traditional PID, and the parameter fluctuation range is reduced to ± 0.2%.

Multi variable coordinated control: It can achieve linkage control of 8 input variables and 4 output variables. For example, in the coordinated control of thermal power units, parameters such as boiler steam pressure, turbine generator load, and water supply are synchronously collected, and the feed pump speed and fuel supply are dynamically adjusted through coordination algorithms to ensure stable operation of the unit under optimal conditions.

Fault self diagnosis and fault tolerance: It has dual diagnostic functions at the hardware level (processor, AD/DA conversion circuit) and software level (algorithm execution, communication link), and fault information is uploaded in real time to the system monitoring station through the communication bus; Support "soft redundancy" configuration (2 control boards as backups for each other), with a primary backup switching time of ≤ 50ms, to avoid control interruptions caused by single point failures.

Interface Expansion Flexibility: The board has 2 expansion interfaces, which can be externally connected to ABB dedicated signal conditioning modules (such as 3ASC25H204 isolation module) and digital expansion boards (such as DIO1616). After expansion, it can support up to 32 AI, 16 AO, 48 DI, and 24 DO channels, adapting to the multi signal acquisition needs of complex industrial sites.

Adaptation devices and collaborative applications

1. Core adaptation equipment

System controller

ABB Advant OCS controllers (such as MASTERPIECE 200) and AC 800M controllers (PM864K01) achieve control instruction interaction and data upload through PROFIBUS DP bus

Actuator driver unit

ABB DSDO 131 digital output unit (driving high-power contactors, solenoid valves), ABB AO810 analog output module (expanding AO channels, driving frequency converters, regulating valves)

Signal conversion unit

ABB DSTF610 terminal unit (for transferring sensor signals, achieving signal isolation and wiring management), ABB 3ASC25H204 isolation module (enhancing AI signal anti-interference capability)

Sensors and actuators

Pressure transmitter (ABB 266HSH series, 4-20mA output), temperature sensor (ABB TSP series, PT100 signal), electric control valve (ABB V183 series, 4-20mA control), frequency converter (ABB ACS880 series)

Auxiliary equipment

ABB PROFIBUS DP bus connector (3RK1901-1BB00), redundant power module (PM861K01-R), system monitoring software (ABB Operator Workplace)

2. Collaborative application case with DSDO 131 and AC 800M controllers: boiler feedwater control for thermal power units

System architecture: It is necessary to achieve precise control of boiler feedwater flow, involving 3 steam pressure AI signals, 2 feedwater flow AI signals, and 1 steam drum water level AI signal. The control output includes 2 feedwater pump frequency converter AO signals, 1 feedwater valve DO signal, and 1 alarm DO signal.

Connection logic:

After the pressure transmitter, flow sensor, and water level sensor signals are transferred through the DSTF610 terminal unit, they are connected to the AI interface of the DAPC100 control board; The control board communicates with the AC 800M controller (PM864K01) through the PROFIBUS DP bus to obtain the set load value of the unit;

DAPC100 runs the "cascade PID+feedforward" control algorithm: with the steam drum water level as the outer loop control objective and the feedwater flow rate as the inner loop feedback, combined with the unit load feedforward signal, outputs a 4-20mA signal to the frequency converter (adjusts the speed of the feedwater pump);

When the water supply flow exceeds the limit, the control board triggers the DSDO 131 digital output unit through the DO interface, cuts off the power supply of the water supply valve (emergency valve closure), and outputs an alarm signal to the monitoring station to achieve safety interlock control.

Core advantage: The high-order algorithm of DAPC100 solves the lag problem of boiler feedwater system, and the water level control accuracy reaches ± 5mm (traditional PID control accuracy is ± 15mm); The high load driving capability of DSDO 131 ensures the reliability of emergency valve closing action, which meets the SIL 2 safety requirements of thermal power units.

Comparison with conventional control modules (such as DAPM100)

Comparing dimensions

ABB DAPC100 3ASC25H203 control board

ABB DAPM100 Conventional Control Module

Core adaptation scenarios

Large scale process control (thermal power units, chemical reactors) requires high-order algorithms and multivariable coordination

Small and medium-sized equipment control (single machine equipment, small production line), only requiring basic PID and logic control

Computing power and algorithms

800MHz dedicated processor, supporting predictive control, multivariable coordination, and 32 control loops

400MHz general-purpose processor, only supports basic PID, 8 control loops

Signal processing accuracy

AI sampling accuracy ± 0.05%, AO output accuracy ± 0.1%, suitable for high-precision adjustment

AI sampling accuracy ± 0.1%, AO output accuracy ± 0.2%, meeting basic control requirements

Redundancy and Fault Tolerance

Support soft redundancy (switching ≤ 50ms), dual fault diagnosis

No redundant function, only basic fault alarm

Expansion capability

Scalable with 32 AI/16 AO/48 DI/24 DO channels

Maximum expansion of 16 AI/8 AO/24 DI/16 DO channels

Cost level

The unit price is about three times that of DAPM100, suitable for critical process control

High cost-effectiveness, suitable for basic control scenarios

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-