ABB DAPI100 (order number: 3AST000929R109) is a high-performance Ethernet communication interface module for industrial automation control systems, belonging to the core adapter series of ABB's industrial communication product family. Its core positioning is to serve as a "data bridge" between industrial equipment and Ethernet networks, enabling bidirectional data exchange between industrial equipment such as PLCs, controllers, I/O modules, intelligent instruments, and upper monitoring systems (SCADA/HMI), enterprise management systems (MES/ERP), and cloud platforms through standardized Ethernet protocols. It solves communication compatibility issues between different devices in industrial sites and is a key component in building transparent and efficient industrial communication networks.

ABB 5SGY3545L0010 3BHB006485R0001 Controller Module

Product Overview

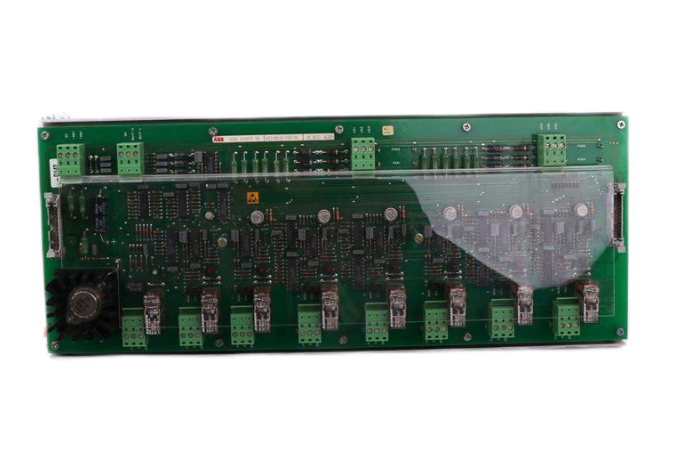

ABB 5SGY3545L0010 (order number: 3BHB006485R0001) is a high-performance controller module for the medium and high voltage industrial control field, belonging to the core control unit series of ABB Advant OCS control system family. Its core positioning is to serve as the "decision-making center" for the control of medium and high voltage motors, power system protection, and precision control of industrial processes. By collecting real-time data from on-site sensors, actuators, and supporting modules, it executes preset control logic and protection algorithms to achieve precise control and safety protection of industrial equipment. It is the core equipment that ensures the stable operation of key production links in industries such as metallurgy, power, petrochemicals, and rail transit.

This module integrates ABB's dual technological accumulation in the fields of power electronics and industrial control, and has the characteristics of fast computing speed, high control accuracy, strong anti-interference ability, and excellent redundancy performance. It has been hardware optimized for the special requirements of medium and high voltage industrial scenarios, supporting multi-channel signal acquisition and multi protocol communication, and can be seamlessly integrated into mainstream control systems such as ABB AC 800PEC and Symphony Plus. It is also compatible with third-party medium and high voltage equipment, greatly reducing system integration complexity and improving the reliability and scalability of control networks.

Core functions and roles

2.1 Multi channel precise data acquisition and computation

The 5SGY3545L0010 controller module is equipped with 16 analog input channels, 32 digital input channels, and 16 digital output channels, supporting standard industrial signal acquisition such as 0-10V and 4-20mA. It can simultaneously collect multiple parameters such as voltage, current, temperature, and pressure of medium and high voltage equipment in real time, with a sampling frequency of up to 1kHz and a sampling accuracy of ± 0.1%. The module is equipped with a high-performance 32-bit DSP processor and FPGA logic unit, with powerful parallel computing capabilities. It can complete multi-channel data filtering, conversion, and logic judgment within 1ms, providing data support for precise control. For example, in the control of medium and high voltage motors, it can quickly calculate the operating parameters of the motor and achieve precise adjustment of speed and torque.

2.2 Exclusive control and protection of medium and high voltage equipment

Module integration of dedicated algorithms for control and protection of medium and high voltage equipment, providing full process functions such as start-up control, speed control, overload protection, short circuit protection, overvoltage protection, undervoltage protection, temperature protection, etc., based on the operating characteristics of medium and high voltage motors, transformers, frequency converters, etc. In the scenario of starting a medium to high voltage motor, the module can smoothly increase the motor speed through a soft start algorithm, avoiding damage to the power grid and equipment caused by the impact of starting current; When the device current exceeds 1.2 times the rated value, the overload protection action can be triggered within 50 μ s, cutting off the control circuit and issuing an alarm signal to minimize the risk of equipment damage.

2.3 Dual redundancy architecture and high availability guarantee

In response to the high reliability requirements of medium and high voltage control scenarios, the module adopts a dual redundancy design of "hardware+communication". At the hardware level, it supports 1+1 hot standby redundancy configuration. The main and backup modules synchronize real-time operation data and control status through a dedicated synchronization bus. When the main module fails, the backup module can switch without disturbance within ≤ 10ms to ensure uninterrupted control flow; At the communication level, it is equipped with dual Ethernet ports and dual PROFIBUS DP interfaces, supporting link redundancy. When the main communication link fails, it automatically switches to the backup link to ensure the continuity of data transmission. The dual redundancy architecture ensures a module system availability of over 99.99%, meeting the continuous operation requirements of critical production processes.

2.4 Multi protocol compatibility and flexible communication

The module supports multiple mainstream industrial communication protocols, equipped with 2 Gigabit Ethernet interfaces, 2 PROFIBUS DP master station interfaces, and 1 CANopen interface, which can achieve bidirectional data exchange with upper monitoring systems (SCADA/HMI), medium and high voltage frequency converters, intelligent instruments, and other controllers. The supported protocols include EtherNet/IP, Modbus RTU/TCP, PROFIBUS DP V1, OPC UA, and ABB dedicated PPA bus protocol, which can upload device operation data to the upper system and receive control instructions issued by the upper system, achieving remote monitoring and centralized management. For example, the operating parameters of medium and high voltage motors can be uploaded to the SCADA system through the Modbus TCP protocol, and control instructions can be received through the EtherNet/IP protocol to adjust the motor's operating status.

2.5 Modular Programming and Function Expansion

The module supports modular programming based on the IEC 61131-3 standard, and operators can develop control logic using various programming languages such as ladder diagram (LD), functional block diagram (FBD), structured text (ST), etc. through ABB dedicated programming software (such as Control Builder M, Symphony Plus Engineering Studio). The module has 8 expansion slots, which can flexibly configure analog input modules, digital output modules, communication expansion modules, etc., to meet the functional needs of different medium and high voltage control scenarios, without the need to replace the module body, reducing system upgrade costs.

Key technical parameters

Order Number

3BHB006485R0001

Product Model

5SGY3545L0010

Product Type

High voltage industrial control dedicated controller module (redundant compatible)

Core processor

32-bit DSP processor (clock speed 1GHz)+FPGA logic unit

Memory configuration

RAM:1GB; Flash: 4GB (supports expansion up to 8GB)

I/O channel configuration

Analog input: 16 channels (4-20mA/0-10V); Digital input: 32 channels (24V DC); Digital output: 16 channels (24V DC)

Sampling frequency and accuracy

Sampling frequency: 1kHz; Sampling accuracy: ± 0.1%

communication interface

2 Gigabit Ethernet ports, 2 PROFIBUS DP master interfaces, 1 CANopen interface

Supported Protocols

EtherNet/IP、Modbus RTU/TCP、PROFIBUS DP V1、OPC UA、ABB PPA、CANopen

redundant function

1+1 hardware hot standby redundancy, switching time ≤ 10ms; communication link redundancy

Working Voltage

DC 24V ± 20% or AC 110/220V ± 10%, dual power redundant input

Working temperature range

-25℃ ~ +65℃

relative humidity

5%~95% (non condensing)

Protection level

IP20 (module body), compatible with the control cabinet, can reach IP54

Electromagnetic compatibility standards

IEC 61000-4-2 (ESD), IEC 61000-4-3 (radiated immunity), IEC 61000-4-6 (conducted immunity)

Installation method

DIN 35mm standard rail installation or rack mounted installation

Structure composition and interface description

4.1 Core Structure Composition

The 5SGY3545L0010 module adopts a high-strength modular structure, mainly composed of six core components: the first is the core computing unit, which includes DSP processor, FPGA logic unit and memory chip, responsible for data operation, logic processing and control instruction generation; The second is the I/O interface unit, which integrates analog and digital signal acquisition and output circuits to achieve signal interaction with field devices; The third is the communication unit, which includes Ethernet, PROFIBUS DP, and CANopen interface circuits, responsible for data transmission and protocol parsing; The fourth is the power management unit, which supports dual power redundant inputs and includes power filtering and overvoltage/overcurrent protection circuits to provide stable power supply for the module; The fifth is a redundant synchronization unit, which includes a dedicated redundant synchronization chip and bus interface to achieve data synchronization and switching control between the main and backup modules; The sixth is the status indicator unit, which consists of multiple sets of LED indicator lights and provides real-time feedback on the operation status of the module.

4.2 Key Interface and Indicator Light Description

-Power interface: located on the left side of the rear of the module, in the form of a phoenix terminal, marked with "PWR1" and "PWR2" to distinguish between main and backup power supplies, supporting DC 24V or AC 110/220V input, equipped with a power status indicator light (green constant light - normal, red light - fault).

-Ethernet interface: 2 RJ45 Gigabit Ethernet ports, labeled as "ETH1" and "ETH2", supporting link redundancy, used to connect to the upper system or other controllers. Each interface is equipped with a link light (green - connected, yellow - data transmission).

-PROFIBUS DP interface: 2 DB9 pin interfaces labeled "DP1" and "DP2", used as the main station to connect medium and high voltage equipment or I/O modules, supporting a maximum transmission rate of 12Mbps, equipped with communication status indicator lights.

-I/O interface: Analog input (AI) and digital input (DI) use Phoenix terminals, labeled "AI1-AI16" and "DI1-DI32" respectively; The digital output (DO) is labeled as "DO1-DO16" and supports both dry and wet contact outputs.

-Redundant synchronization interface: 1 dedicated Phoenix terminal interface labeled "RED SYNC", used for redundant synchronization signal transmission between primary and backup modules, ensuring data synchronization and interference free switching.

-Debugging interface: 1 USB Type-B interface (labeled "DEBUG") and 1 RS-232 interface (labeled "CONFIG"), used to connect to a computer for program download, parameter configuration, and fault diagnosis.

-Status indicator lights: There are 6 sets of indicator lights at the front of the module, including power light (PWR), running light (RUN, green flashing - normal), fault light (ERR, red on - fault), redundancy status light (RED, yellow - main module, green - backup module), I/O status light (I/O, green - normal), and communication status light (COM, green - normal).

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-