Siemens SENTRON intelligent circuit protection equipment: full analysis of communication, measurement, and digital management

Siemens SENTRON intelligent circuit protection equipment: full analysis of communication, measurement, and digital management

In modern distribution systems, traditional circuit protection equipment only provides basic overload and short circuit protection functions, lacking real-time monitoring and data feedback of electrical status, making it difficult to meet the growing demand for system reliability, predictability, and intelligent management. The Siemens SENTRON series of circuit protection equipment with communication and measurement functions has emerged. It not only continues reliable protection performance, but also achieves transparency, warning and remote management of the distribution system through integrated communication, measurement and data acquisition functions, becoming a key component of intelligent distribution and energy management.

The limitations of traditional protection and SENTRON's innovation

Traditional circuit breakers, fuses, and other protective devices perform tripping operations when faults occur, but cannot record key information such as the cause of the fault, current and voltage trends, and equipment operating status. Operations personnel often need to conduct on-site inspections, which is inefficient and difficult to achieve preventive maintenance. The SENTRON series devices collect real-time electrical parameters such as current, voltage, power, energy, temperature, and residual current through built-in measurement sensors and wireless communication modules. The data is wirelessly transmitted to the central gateway - SENTRON Powercenter 1000, and then uploaded to the monitoring system or cloud platform. This trinity design of "protection+perception+communication" shifts circuit protection from passive response to active warning and intelligent management.

System Core: SENTRON Powercenter 1000

SENTRON Powercenter 1000 is the data transmission and reception center of the system, which adopts a compact 1TE wide DIN rail installation design and supports 24V DC (SELV) power supply. Its core functions include:

Wireless aggregation: It can perform bidirectional wireless communication with up to 24 SENTRON communication devices (such as circuit breakers, fuses, auxiliary switches, etc.), operating in the 2.4GHz frequency band and supporting AES-CCM encryption.

Multi interface upload: Provides Ethernet interface (supporting Modbus TCP) and Bluetooth interface (BLE 5.1), allowing real-time access to data through local networks or mobile devices.

Data storage: The built-in memory can store the trend of key measurement values for up to 30 days, and supports historical query and analysis.

Flexible networking: Supports up to 4 Powercenter 1000 devices working in parallel, avoiding interference by automatically or manually selecting wireless channels.

Rich terminal device types and functional features

The SENTRON series covers a variety of communicable terminal protection devices, suitable for different application scenarios:

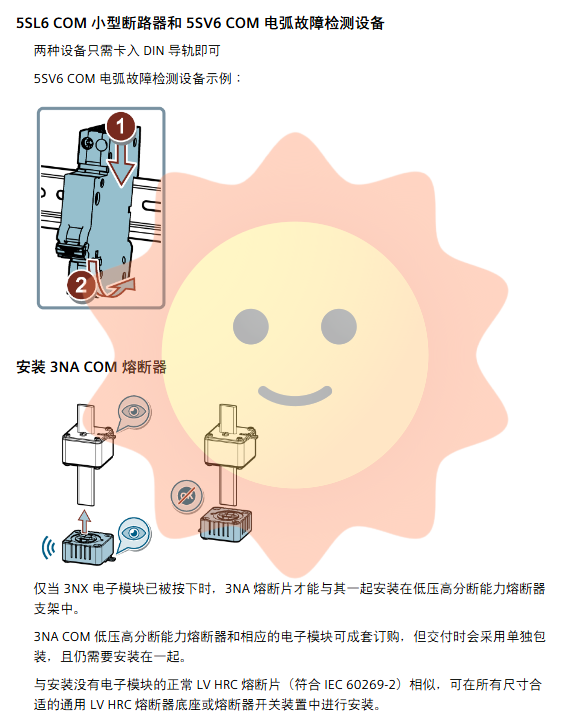

5SL6 COM miniature circuit breaker

In addition to conventional overload and short circuit protection, it integrates high-precision electrical measurement functions (current, voltage, power, energy, frequency, temperature), and some models support residual current monitoring (RCM, compliant with IEC 62020-1), which can detect residual current in multiple frequency bands and distinguish fault types such as insulation aging and high-frequency interference.

5SV6 COM Arc Fault Detection Device (AFDD)

By combining circuit breakers and arc fault protection functions, series and parallel arcs can be detected to prevent electrical fires. Simultaneously provide complete electrical parameter measurement and communication alarm.

3NA COM fuse

On the basis of standard NH fuses, electronic modules are integrated and powered from the main circuit through energy harvesting technology without the need for additional wiring. Real time monitoring of current and temperature, warning of overload trends, and avoiding unexpected circuit breakers.

5ST3 COM auxiliary switch and fault signal contact

Used for retrofitting traditional non communication circuit breakers, the additional module only occupies 0.5TE and can detect switch status, temperature, operation times, and wirelessly upload.

3RV2 COM wireless auxiliary and signal switch

Adapt to 3RV2 motor starter protector, monitor its switch status, tripping reasons (overload/short circuit), temperature, and operating time.

5ST3 COM Remote Control Assist (RCA)

Supports remote switch control, automatic reclosing (ARD), and RCD/insulation resistance testing (compliant with IEC 63024), suitable for situations that require remote operation and automatic recovery.

Installation, Debugging, and Parameter Setting

4.1 Installation points

Environmental requirements: The equipment is suitable for environments with pollution level 2 (3NA COM can be used for level 3), with a working temperature of -25 ° C to+60 ° C.

Wireless layout: It is recommended that the distance between the terminal equipment and Powercenter 1000 should not exceed 3 meters, avoiding metal barriers and placing them in the center as much as possible to ensure communication quality.

Power connection: 5SL6 COM and 5SV6 COM need to be connected to the phase line and neutral line (230V AC); Powercenter 1000, 5ST3 COM, etc. use 24V DC power supply and support screw free terminal daisy chain connection.

4.2 Debugging Process

Device addition: Use the mobile application "SENTRON Powerconfig mobile" or PC software "SENTRON Powerconfig" to add the device to the project by scanning the Data Matrix Code (including RF code) on the device or manually entering the MAC address and installation code.

Pairing Connection: Pair the terminal device with Powercenter 1000 in the application to establish a secure wireless connection.

Parameter settings: configurable device name, alarm threshold (current, voltage, temperature, residual current, etc.), radio transmission power, time zone synchronization, etc.

Data viewing: Real time viewing of measurement values, alarm information, trend curves, and support for exporting project files (. splx format) for backup or migration.

4.3 Advanced Features

Time synchronization: Supports SNTP protocol to ensure consistent timestamps for all devices, facilitating event sorting and analysis.

Firmware update: Unified push through Powercenter 1000, supporting wireless upgrade of the entire system.

Modbus TCP integration: Provides a complete register mapping table for third-party systems (such as SCADA, energy management systems) to directly read data and control devices.

Intelligent diagnosis, warning and maintenance support

5.1 Multi level alarm mechanism

The device supports multiple types of alarms, including:

Electrical parameters exceeding limits: overcurrent, undercurrent, overvoltage, undervoltage, high temperature.

Lifespan warning: The number of operation cycles, trip times, and running time are approaching the set threshold.

Residual current alarm: RCM equipment can provide segmented warnings for AC or pulsating DC residual current.

Status alarm: equipment trip, communication interruption, self-test failure, etc.

Alarm can be notified to users in real-time through various methods such as LED indicator lights (flashing frequency and color differentiation level), mobile application messages, Modbus TCP status words, etc.

5.2 Data Recording and Traceability

Powercenter 1000 stores key trend data (such as current, voltage, power, temperature, etc.) with a time resolution ranging from 10 seconds to 1 day, and can be saved for up to 30 days. By combining event logs (such as trips, alarms, parameter changes), users can trace the historical status of the system and analyze the root cause of faults.

5.3 Predictive Maintenance Support

By continuously monitoring electrical parameters and equipment status, the system can identify potential risks in advance, such as line overload, insulation degradation, and contact overheating, to avoid unexpected power outages. Statistical information such as operating hours and frequency of operations also provide a basis for planned replacement and maintenance.

Typical application scenarios and system integration

The SENTRON intelligent circuit protection system is suitable for various distribution scenarios that require high reliability, visualization, and remote management:

Commercial buildings and data centers: Real time monitoring of energy consumption in each circuit, warning of overload, and rapid fault location.

Industrial production line: Monitor motor branch current and temperature to prevent shutdown caused by overload or insulation failure.

Infrastructure and Public Facilities: Remote Operation and Automatic Recovery Function (ARD) enhances power supply availability.

Renovation project: Quickly upgrade existing circuit breakers by adding communication modules (such as 5ST3 COM) without the need to replace the main equipment.

The system can be seamlessly integrated into the Siemens digital ecosystem:

SENTRON Powermanager: A professional energy management system that conducts in-depth energy efficiency analysis and generates reports.

SENTRON Powercenter 3000: IoT gateway that provides web visualization, data archiving, email alerts, and cloud connectivity (such as MindSphere).

Third party platform: Connect to various SCADA, BMS, or self-developed platforms through the standard Modbus TCP protocol.

7、 Safety and Compliance

Electrical safety: All equipment complies with relevant standards such as IEC and EN, and the protection function is independent of the communication module, ensuring reliable tripping even in case of communication interruption.

Communication security: Wireless pairing uses a unique installation code and AES-CCM encryption, and Bluetooth connections require PIN code verification.

Network security: Supports firewall, static IP, VPN access. It is recommended to deploy and restrict external access within the local area network.

Complete certification: The equipment has multiple certifications such as CE, RED, VDE, KEMA, etc., and complies with radio and EMC specifications.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA