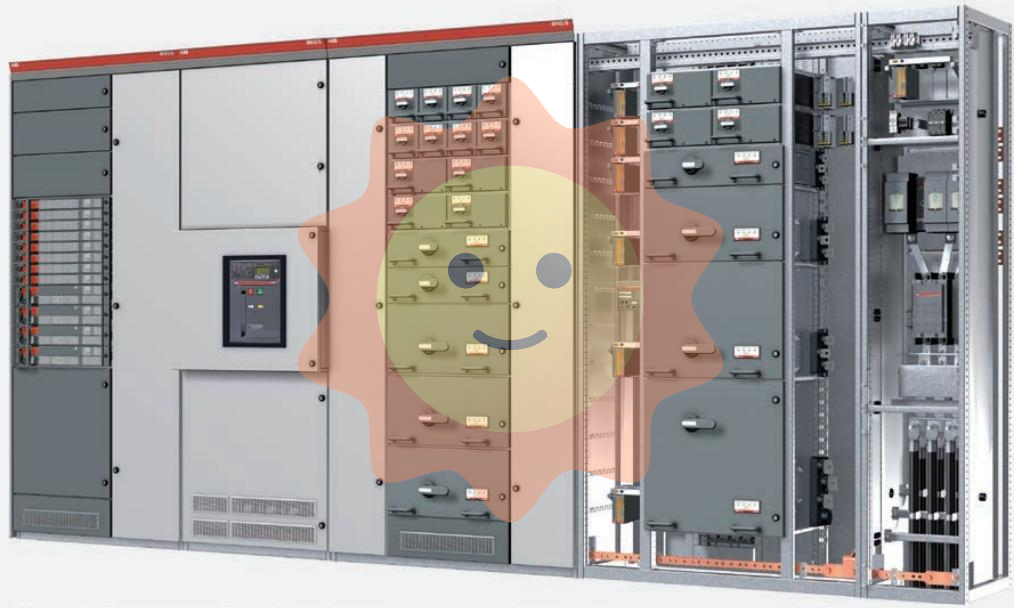

In the complex network of industrial electrical systems, the drive contactor as a key hub between the power supply and the load,

and its performance is directly related to the stability and reliability of the system operation.

ABB EHDB280 drive contactor is specially designed for the harsh industrial application scenarios,

by virtue of the excellent electrical performance, durable structural design and convenient maintenance characteristics,

to become the mainstay of the industrial power control field.

ABB EHDB280 drive contactors: powerful protection for industrial power control

In the complex network of industrial electrical systems, the drive contactor as a key hub between the power supply and the load,

and its performance is directly related to the stability and reliability of the system operation.

ABB EHDB280 drive contactor is specially designed for the harsh industrial application scenarios,

by virtue of the excellent electrical performance, durable structural design and convenient maintenance characteristics,

to become the mainstay of the industrial power control field.

Electrical Performance Parameters

Rated Voltage: Suitable for medium and high voltage systems, the common rated voltage covers 3kV, 6kV and 10kV, etc.,

which can be seamlessly adapted to industrial power grids with different voltage specifications.

Whether it is high-power motors in large industrial facilities or precision equipment that requires high voltage stability,

EHDB280 can provide stable and reliable power access to ensure stable operation of equipment in different voltage environments.

Rated current: With a strong current carrying capacity of up to 280A,

the EHDB280 is able to cope with the high current demand during the startup and operation of high-power motors.

At the moment of motor startup, an inrush current several times of the rated current is often generated,

EHDB280 can easily carry these inrush currents by virtue of its excellent design of rated current,

guaranteeing smooth startup of the motor and continuously providing stable current for the motor under full load or overload conditions,

avoiding abnormal operation or damage to the motor due to insufficient current.

Breaking capacity: With excellent short-circuit breaking capacity,

it can quickly cut off the fault current in a very short time (millisecond response) in the face of short-circuit and other sudden electrical faults.

This feature is essential to effectively prevent the fault current from spreading in the electrical system,

to protect motors, lines and other electrical equipment from the impact of high current damage,

for the industrial electrical system to build a solid safety line of defense,

to ensure that the system in the event of a failure in a timely manner to stop the loss, to maintain the overall stability.

Second, the structural design features

Arc extinguishing system: the use of advanced and efficient arc extinguishing technology and materials,

such as vacuum arc extinguishing chamber or magnetic blowing arc extinguishing device.

Vacuum arc extinguishing chamber using a high vacuum environment to rapidly cool and extinguish the arc,

significantly reducing contact erosion, significantly extending the service life;

magnetic blowing arc extinguishing device with the help of a magnetic field,

the arc will be quickly blown into the arc extinguishing grids, accelerating the arc cooling and extinguishing process.

In industrial scenarios with frequent switching operations,

this highly efficient arc extinguishing system ensures that the contactor reliably breaks the circuit,

greatly reduces the risk of malfunction caused by the arc, and guarantees the long-term stable operation of the equipment.

Contact material: The main contacts are made of silver alloy and other high-performance conductive materials,

with excellent conductivity and anti-melting performance. In the process of long-term frequent high current,

the contacts are not easy to oxidize, wear and tear, and always maintain a stable contact resistance,

effectively avoiding problems such as heat and fire caused by poor contact, to ensure the stability and reliability of the current transmission,

reduce the frequency of maintenance of the equipment, and improve production efficiency.

Protection level: The overall protection level reaches IP20 and above, which can effectively prevent foreign objects

with a diameter of more than 12mm and fingers from touching the internal electrically charged parts,

and in the dusty and crumbly industrial environment, it can resist the intrusion of dust, small particles

and other debris to ensure the normal operation of the internal electrical components and prolong the service life of the contactor.

For some special application scenarios, higher protection level models are also available, such as IP65 protection level products,

which can effectively prevent dust and water splash, and are suitable for humid and watery industrial environments,

such as food processing factories, ships and other places.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

email:1583694102@qq.com

wang@kongjiangauto.com