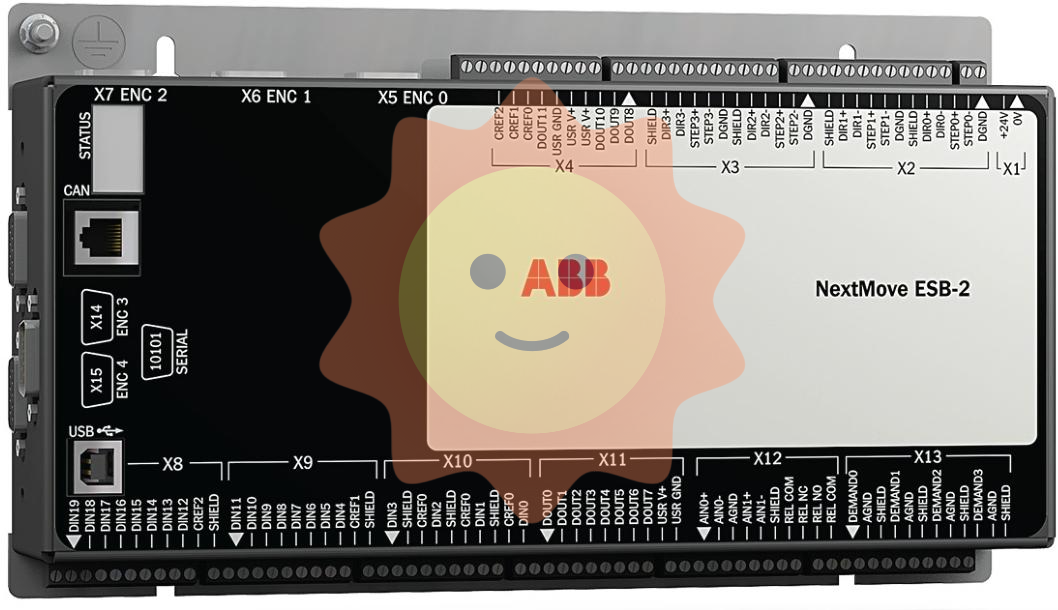

In the field of industrial automation, fieldbus module, as the “nerve center” connecting field equipment and control system,

plays a key role in the accuracy and stability of data transmission.ABB FI830F Fieldbus Module, by virtue of its advanced technology,

reliable performance and flexible application, has become the core equipment for industrial field communication.

ABB FI830F fieldbus modules are the core devices for industrial field communication, providing efficient data interaction solutions

for various industrial production scenarios.

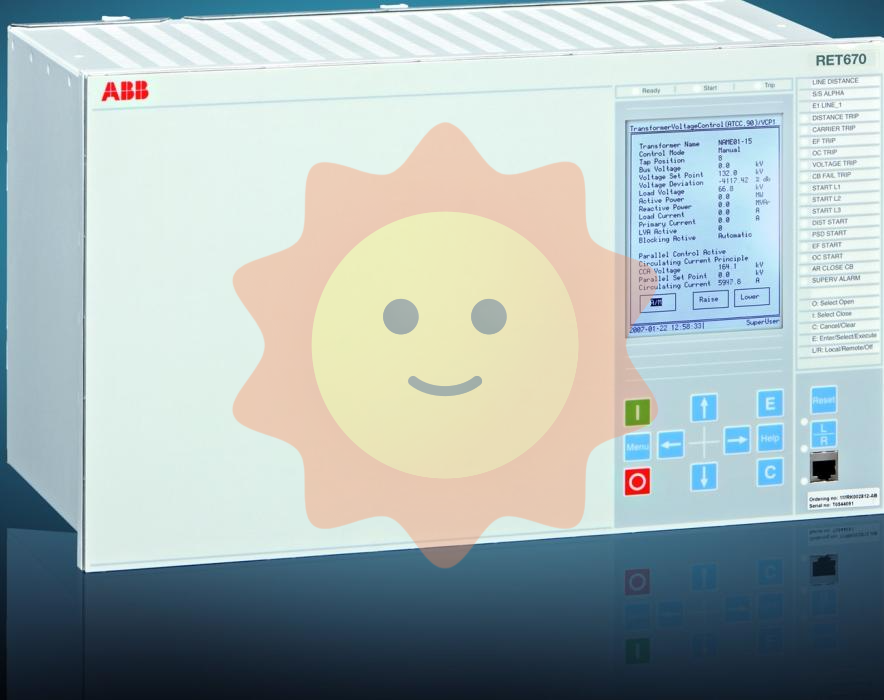

ABB FI830F Fieldbus Module

In the field of industrial automation, fieldbus module, as the “nerve center” connecting field equipment and control system,

plays a key role in the accuracy and stability of data transmission.ABB FI830F Fieldbus Module, by virtue of its advanced technology,

reliable performance and flexible application, has become the core equipment for industrial field communication.

ABB FI830F fieldbus modules are the core devices for industrial field communication, providing efficient data interaction solutions

for various industrial production scenarios.

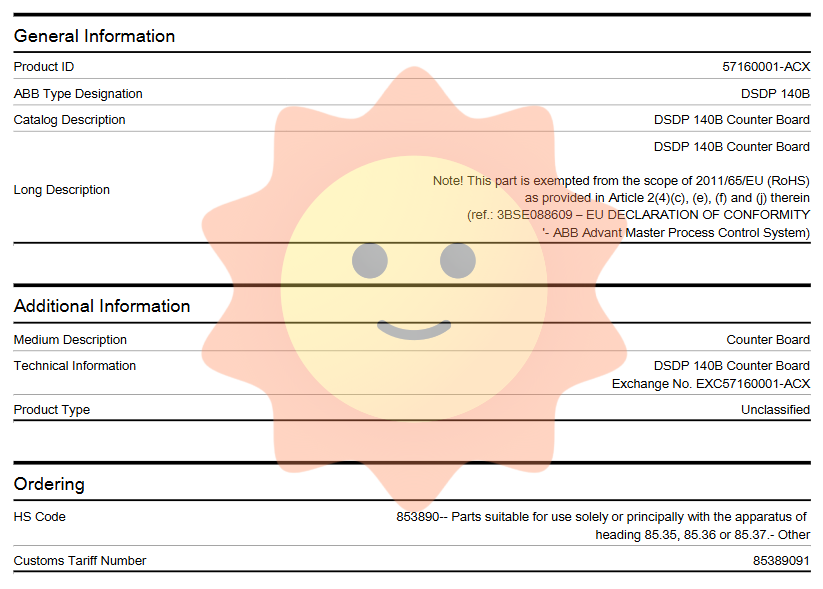

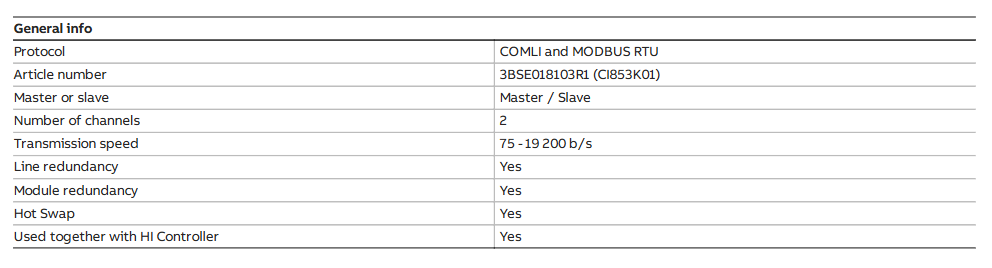

Basic Product Information

Product Positioning: FI830F is a high-performance fieldbus module designed for industrial automation system,

aiming at realizing stable communication between field devices and control system,

and meeting the strict requirements of real-time, reliability and accuracy in the industrial production process.

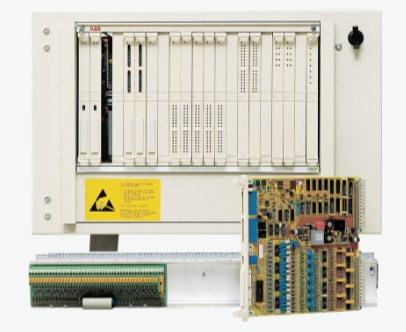

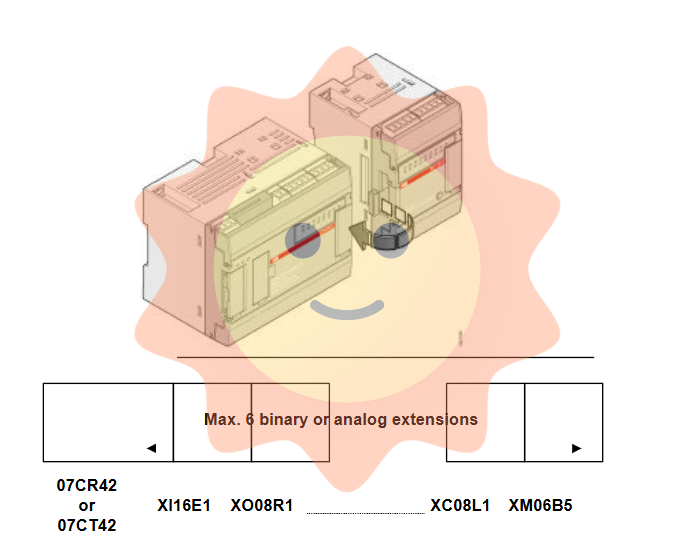

Belongs to the series: belongs to the important part of ABB AC 800F controller series,

can be seamlessly integrated with other devices of the series, to build a complete industrial automation control system,

and give full play to the overall effectiveness of the system.

Electrical characteristics

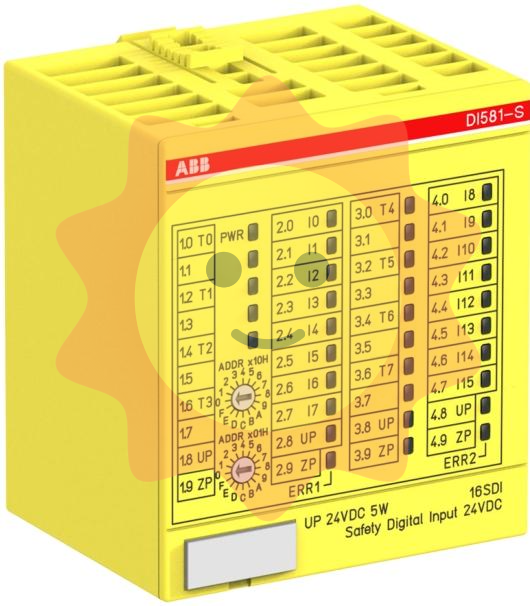

Signal types and channels: It supports a variety of analog input signals, including 4-20mA current signals and 0-10V voltage signals, etc.,

which can meet the needs of accessing different types of sensors.

Usually equipped with 8 analog input channels, it can collect data from multiple field devices at the same time to improve the data collection efficiency,

which is suitable for complex industrial monitoring scenarios, such as the simultaneous collection of temperature, pressure,

flow rate and other parameters from multiple reactors in the chemical production process.

Accuracy and resolution: With high precision data acquisition capability and 16-bit resolution,

it can accurately capture the subtle changes in the field signals to ensure the accuracy of the data.

In industrial production, even small parameter fluctuations can be accurately monitored, providing a reliable basis for precise control,

such as in the manufacture of precision instruments for accurate control of processing parameters.

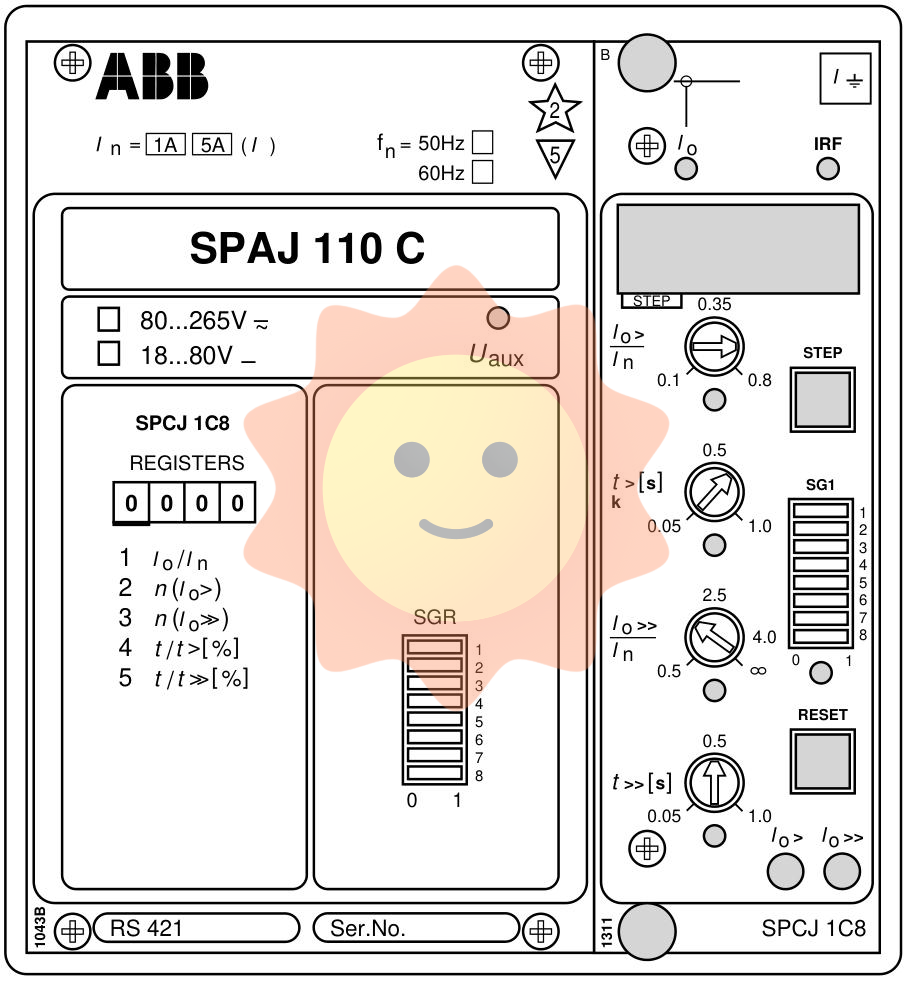

Isolation characteristics: the electrical isolation design between each input channel and between the channel and the system,

the isolation voltage can reach 500V AC, effectively preventing signal interference and electrical faults affecting each other.

In the complex electromagnetic environment of the industrial site, this isolation feature can guarantee the stable operation of the module,

avoid data errors or equipment damage caused by interference, and improve the reliability and safety of the system.

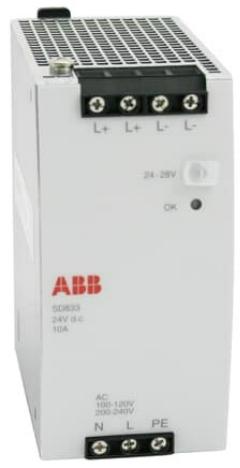

Power supply requirements: the operating voltage is generally 24V DC, with a certain voltage tolerance range to adapt to the voltage fluctuations

that may exist in the industrial field. Low power consumption, in order to ensure high-performance data processing and communication at the same time,

reduce energy consumption, reduce the need for heat dissipation, easy to install and use in a variety of industrial control cabinets.

Functional advantages

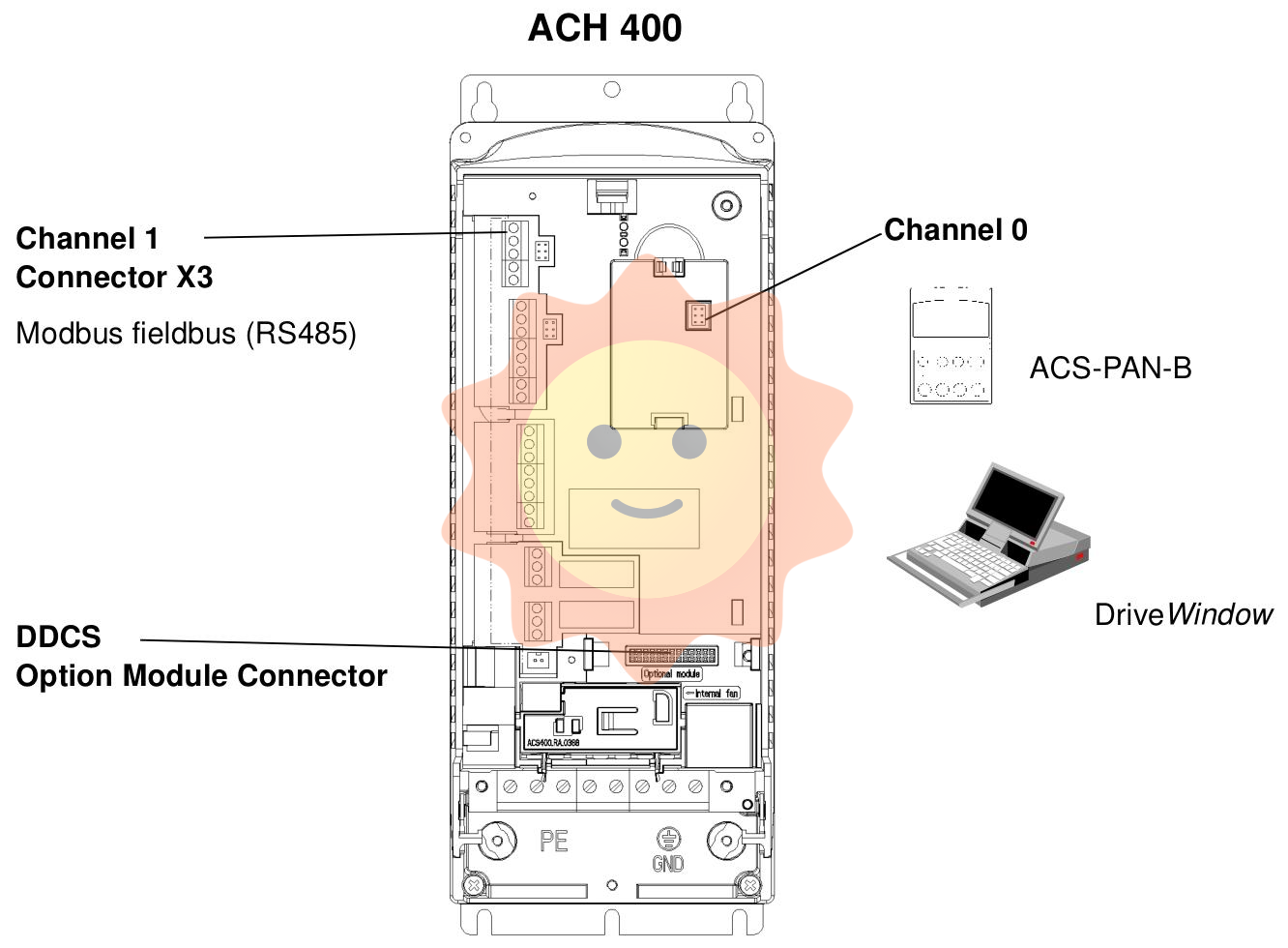

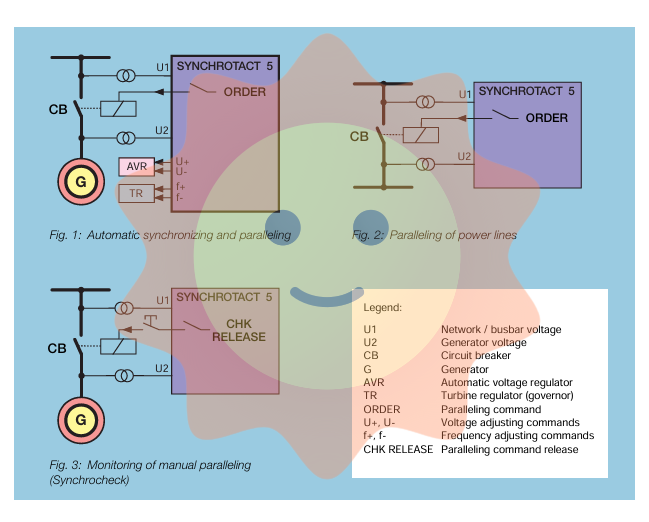

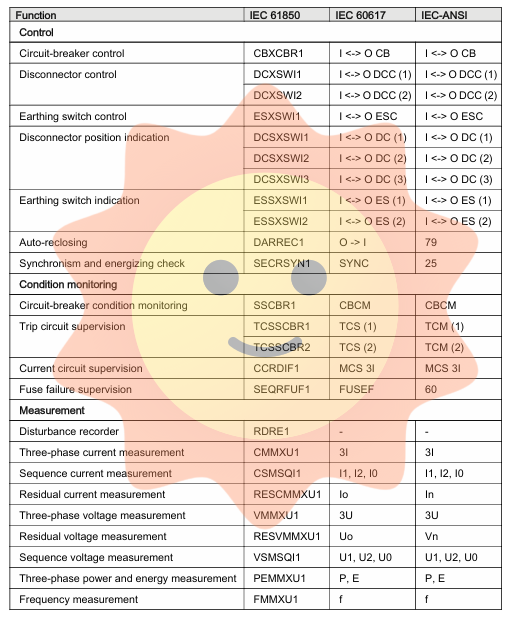

Fieldbus communication protocol: It supports mainstream fieldbus communication protocols such as Profibus DP,

which has high-speed data transmission capability and strong anti-interference performance,

and can realize efficient communication between the module and PLC, DCS and other control systems as well as other field devices.

Through this protocol, FI830F module can transmit data quickly and accurately to ensure real-time monitoring

and precise control of industrial production processes, which meets the requirements of industrial automation for real-time and reliable communication.

Self-diagnosis and fault handling: The built-in perfect self-diagnosis function can monitor the module's operation status

and communication connection in real time. Once a fault is detected, such as channel failure, communication interruption,

power supply abnormality, etc., the module will immediately issue an alarm signal and transmit the fault information to the control system through the fieldbus.

At the same time, the module also has a fault isolation function, when a channel failure,

will not affect the normal work of other channels, easy to quickly locate and troubleshooting,

reduce downtime and improve the continuity of industrial production.

Flexible Configuration and Programming:

The module supports flexible configuration and programming through ABB's Control Builder software,

which allows users to conveniently set the module's parameters, such as input signal type, range, filtering time constant, etc.,

according to the actual application requirements. In addition, the module's communication parameters can also be configured to achieve compatibility

with different control systems and field devices. This flexible configuration allows the FI830F module to adapt to diverse industrial application scenarios

and meet the individual needs of different users.

Data Processing and Conversion: With powerful data processing capability,

it can perform pre-processing operations such as filtering, linearization and engineering conversion on the raw data collected.

For example, the current or voltage signals collected by the sensor can be converted into actual physical quantities (such as temperature, pressure, flow, etc.),

and the data format can be converted according to the requirements of the control system, which is convenient for the control system to analyze and process.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

email:1583694102@qq.com

wang@kongjiangauto.com