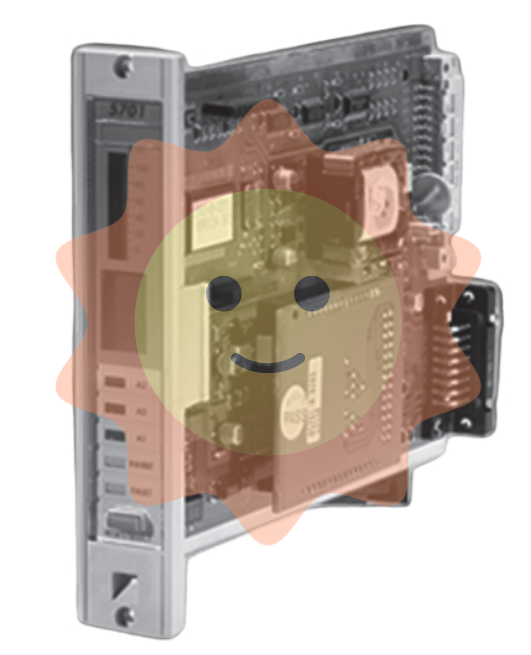

The SST-PFB-SLC is a ProfiBus scanner for the SLC500. It enables communication between SLC processors (SLC 5/03 or later) and DP remote I/O devices on the ProfiBus network.

It acts as a ProfiBus DP remote I/O scanner and can scan up to 96 slave devices. The scanner supports up to 244 bytes of input data and 244 bytes of output data. If you use the SST ProfiBus configuration tool to configure the scanner you can have up to 1000 words of input data and 1000 words of output data. If you configure the scanner with Siemens COM PROFIBUS, it supports a total of 160 words of input data and 160 words of output data.

The scanner can be located in any slot in the local SLC chassis except slot 0 (reserved for SLC processors). You can have multiple scanner mounts in the same place and the scanner supports all standard ProfiBus baud rates (9600, 19200, 93.75k, 187.5k, 500k, 750k, 1.5M, 3M, 6M, 12M) You can use the SST ProfiBus I/O configuration tool or the Siemens COM PROFIBUS configuration software on a DP network.

The SST configuration tool exports the configuration to a *.bss file (binary), while COM PROFIBUS exports the configuration to a *.2bf file (binary). You can upload the configuration to the scanner via the serial port on the scanner, transferring using Xmodem from any serial communication software. The scanner stores this configuration in the scanner's flash memory so that you don't need to upload the configuration every time you start SLC. Input and output data from devices are mapped to SLC I, O, M0, and M1 files. The mapping depends on the address you assign in the configuration and you can create it using any of the configuration tools.

The scanner does not need to set G files in SLC. All configurations are made using the SST configuration tool or COM PROFIBUS.

The scanner maintains the following status information about the network and the I/O modules on the network:

• Slave device status for each slave device

• Network diagnostic counters

•DP master diagnostic counter

•FDL diagnostic counter

Choose Xiamen control Smith after sale worry

Excellent product quality

Only cooperate with manufacturers of first-line brands in the industry

Imports/Products

Good pre-sale service

Communicated with customers repeatedly about product model, quality, price and delivery date

Work with the customer to determine the best solution

Address user concerns in advance

Business execution in place

Ordered products delivered on time

Make perfect delivery plan to ensure the time limit

Assist users to handle the acceptance procedures

Perfect after-sales service

During the warranty period, problems will only be replaced and not repaired

Never put a problem on the back of your head

Service hotline 7x24 hours service

Solemn promise

1. All the items sold by the company, module card parts, etc., the quality problems arising from normal use during the warranty period are replaced free of charge, and there is no evasion.

2. For materials and equipment that have not been discontinued beyond the warranty period, only the cost of relevant parts will be charged for quality problems.

3. Provide replacement models and equipment replacement process services for discontinued materials and equipment.

4. Customers have purchased materials and equipment, lifetime free upgrade system software, related technical information provided free of charge.

5. Visit the use of materials purchased by customers from time to time, and solve any problems in time.

6. The company hotline provides 24-hour service, and the questions raised by customers are answered within 1 hour.

7. Not done, the company spirit of "thoughtful service, responsible to the end" attitude, from the customer's point of view to solve the problem, with serious and rigorous enterprise style, dedicated to each customer service.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com