Manufacturers

ABB

Model(s)

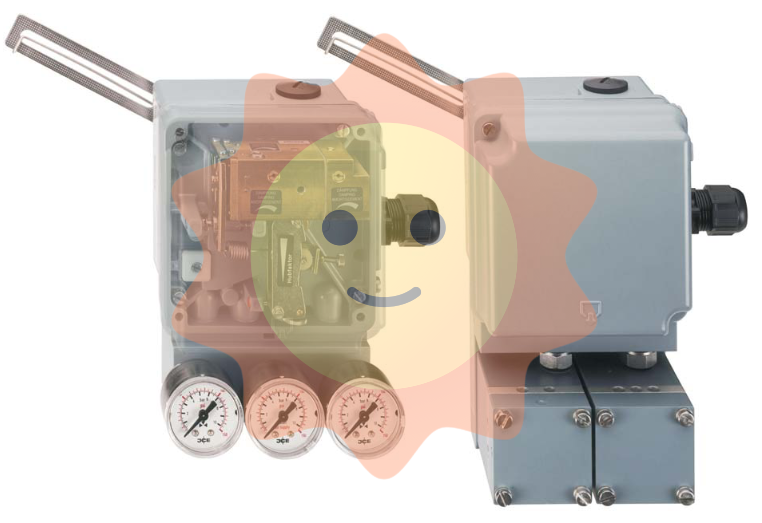

ABB Advant Controller 31, ABB Advant OCS

Additional Information

8 binary inputs, 6 relay outputs, 120/230 V a.c. power supply

Estimated Shipping Size

Dimensions: 4.0" x 4.0" x 5.0"

(10.2 cm x 10.2 cm x 12.7 cm)

Weight: 1 lbs 13.0 oz (0.8kg )

Country of Origin: France

Ships from Webster NY, USA

ABB 1SBP260021R1001 07CR41 Advant Controller Basic Unit

Basic Information

Model and Series:

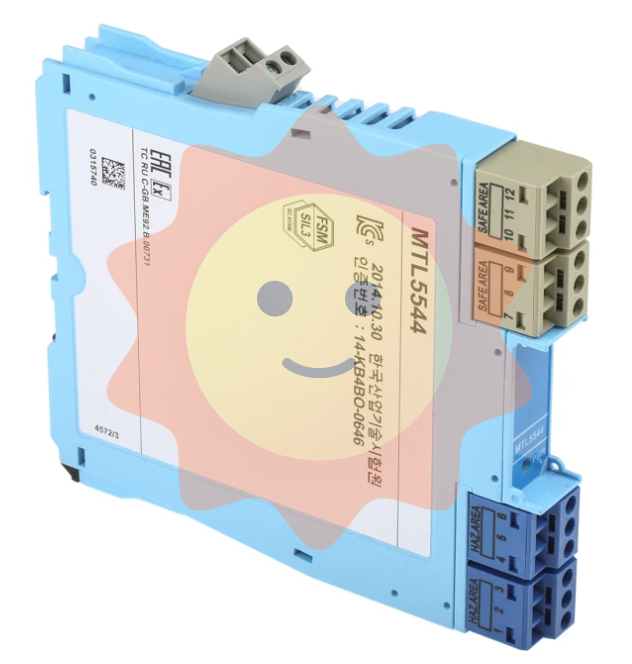

The model number 1SBP260021R1001 belongs to ABB's 07CR41 Advant Controller Basic Unit. In industrial automation control systems, the basic unit is the core part of the whole system, providing basic support for the realisation of various control functions.

Appearance and size guess:

Considering its function as a Basic Unit and the possible installation environment, it is probably a rectangular shaped device. The length is probably around 30 - 40 cm, the width around 20 - 30 cm, and the thickness probably between 10 - 20 cm. The weight is estimated to be in the region of 3 - 6kg, a size and weight that would facilitate installation in a control cabinet or console.

Origin speculation:

ABB's high-end industrial control equipment of this type is usually produced in regions with advanced industrial manufacturing technology, most likely from European countries such as Sweden. These regions have advanced electronic manufacturing technology and strict quality control system, which helps to ensure the high quality and reliability of the basic unit, so that it can operate stably in complex industrial environments.

Performance Features

Control function:

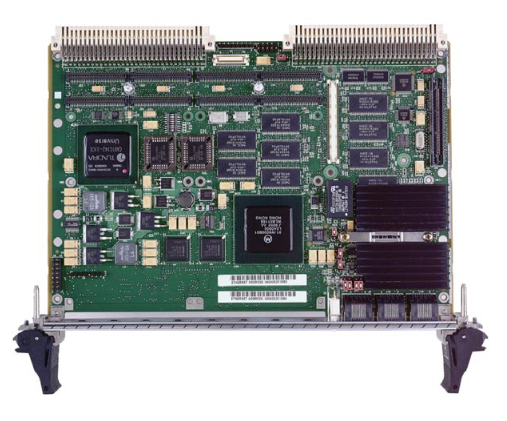

The unit is equipped with powerful control capabilities and is capable of executing a wide range of control strategies and logic operations. It can process signals from various input devices, such as temperature, pressure, position and other signals from sensors, and generate output signals according to preset control procedures and algorithms to control the operation of industrial equipment. For example, in an automated production process, it can control the start and stop of motors, the opening and closing of valves and other operations according to the position of materials and the status signals of the equipment to realise an automated production process.

It supports a variety of control modes, such as open-loop control and closed-loop control. In closed-loop control mode, it receives feedback signals, such as actual temperature, pressure, or speed signals, compares them with setpoints, and then adjusts the outputs through control algorithms, such as PID (Proportional-Integral-Differential), to stabilise the actual physical quantities near the setpoints. This mode of control is important in industrial applications where precise control of physical quantities is required, such as the chemical, power and other process industries.

Data processing and storage capability:

It is capable of handling large amounts of data efficiently. It can receive and process digital and analogue signals from multiple input channels, perform data conversion, filtering, calculations and other operations. For example, for analogue signals, it can perform high-precision analogue-to-digital conversion to convert continuous analogue signals into digital signals for processing. At the same time, it also has a certain data storage capacity, and can store control procedures, configuration parameters, historical data and other information. These stored data can be used for fault diagnosis, data analysis, process optimisation and other purposes.

Communication interface diversity:

Support for a variety of communication interfaces is key to enabling integration with external devices and systems. These may include Ethernet interfaces, RS-485 interfaces, CAN bus interfaces, and more. Ethernet interface can be easily accessed to the factory's LAN to achieve communication with the host computer, other controllers or remote monitoring system; RS-485 interface is suitable for connecting some traditional industrial equipment, such as sensors and actuators with RS-485 communication function; CAN bus interface is widely used in some distributed control systems that require high real-time and reliability, such as equipment control in the production line of automobile manufacturing. The CAN bus interface is widely used in distributed control systems that require high real-time and reliability, such as equipment control in automotive production lines.

Reliability and stability:

High reliability design is adopted to ensure stable operation in industrial environment. In terms of hardware, the use of high-quality electronic components, with good anti-interference ability, can work normally in harsh industrial environments (such as high temperature, high humidity, strong electromagnetic interference, etc.). At the same time, in terms of software, there may be a perfect fault detection and recovery mechanism, when there is a programme error, communication interruption, etc., it can automatically try to recover or take appropriate emergency measures to protect the continuity of the control process.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com