The ABB 128877-103 high-precision industrial control module is a specialized functional module designed for micro/millivolt precision control scenarios, belonging to the ABB industrial control module system. Its core function is to achieve high-precision acquisition of weak signals in industrial sites, execution of complex closed-loop control algorithms, and multi parameter collaborative adjustment, filling the precision gap of conventional control modules in the field of ultra precision. Compared to the previously analyzed TC820-1 temperature control module (with an accuracy of ± 0.1 ℃), its analog acquisition accuracy has been improved by more than 10 times, and the control response speed has been shortened to the microsecond level. It can be adapted to scenarios such as semiconductor manufacturing, optical equipment, and precision machine tools that require control accuracy of "micrometer level displacement" and "millivolt level voltage". This module can seamlessly integrate with the PM861K01 processor and CI853-1 communication module of the AC 800M series, building a complete precision control system of "high-precision acquisition high-order operation multi protocol interaction". It is a key component for achieving ultra precision production in high-end manufacturing industry.

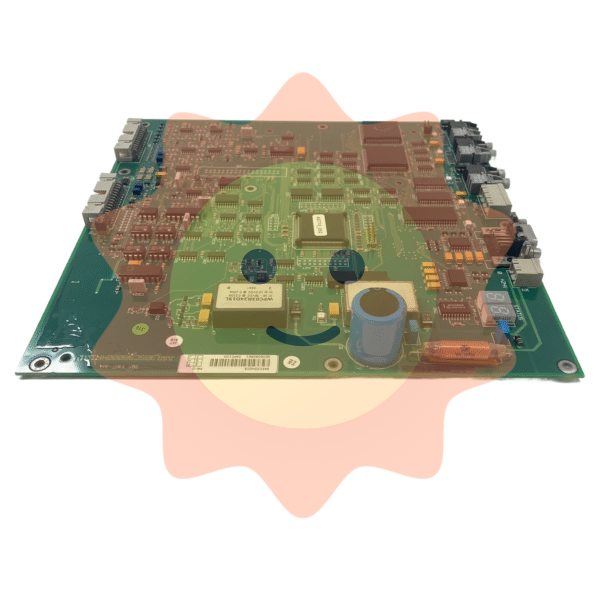

ABB 128877-103 High Precision Industrial Control Module

Product core positioning

The ABB 128877-103 high-precision industrial control module is a specialized functional module designed for micro/millivolt precision control scenarios, belonging to the ABB industrial control module system. Its core function is to achieve high-precision acquisition of weak signals in industrial sites, execution of complex closed-loop control algorithms, and multi parameter collaborative adjustment, filling the precision gap of conventional control modules in the field of ultra precision. Compared to the previously analyzed TC820-1 temperature control module (with an accuracy of ± 0.1 ℃), its analog acquisition accuracy has been improved by more than 10 times, and the control response speed has been shortened to the microsecond level. It can be adapted to scenarios such as semiconductor manufacturing, optical equipment, and precision machine tools that require control accuracy of "micrometer level displacement" and "millivolt level voltage". This module can seamlessly integrate with the PM861K01 processor and CI853-1 communication module of the AC 800M series, building a complete precision control system of "high-precision acquisition high-order operation multi protocol interaction". It is a key component for achieving ultra precision production in high-end manufacturing industry.

Key technical parameters

(1) Signal acquisition and control accuracy parameters

Advantages compared to conventional modules (TC820-1)

Input channel configuration

8 differential analog inputs (supporting voltage/current/resistance signals), 2 pulse signal inputs (for displacement feedback)

New pulse signal input, compatible with precision feedback equipment such as grating rulers and encoders

Input signal type

Voltage signal: ± 10 mV, ± 100 mV, ± 1 V, ± 10 V; Current signal: 4-20 mA, 0-20 mA; Resistance signal: Pt1000 (accuracy ± 0.001 Ω)

Supports millivolt level weak voltage signals, with conventional modules only supporting a minimum of 0-10V

Collection accuracy

Voltage signal: ± 0.001% full scale (accuracy ± 0.1 μ V at ± 10 mV range); Current signal: ± 0.002% of full scale; Resistance signal: ± 0.0005% of full range

Improve accuracy by 10-20 times to meet millivolt/micro European level acquisition requirements

Control algorithm

Built in adaptive PID, fuzzy PID, sliding mode variable structure control, Kalman filter algorithm, supporting custom C language control logic

Add sliding mode control and Kalman filter to adapt to nonlinear precision systems

Control cycle

Minimum control cycle of 10 μ s, supporting dynamic adjustment of cycle (10 μ s-100 ms)

The control cycle is shortened to microsecond level, with a minimum of 10 ms for conventional modules

(2) Hardware and power supply parameters

Power supply specifications

Input voltage 24 VDC (allowable fluctuation range ± 5%, requires regulated power supply), power consumption ≤ 3 W, low ripple power supply requirement (ripple ≤ 10 mVp-p)

Size specifications

Width 35mm x height 95mm x depth 150mm, ultra-thin design, suitable for compact installation space of precision equipment, compatible with 35mm DIN rail

Environmental adaptability

Working temperature -10 ℃ to+60 ℃ (requires constant temperature control, temperature fluctuation ≤ ± 0.5 ℃), storage temperature -40 ℃ to+85 ℃; Relative humidity of 30% to 60% (no condensation); Vibration resistance level IEC 60068-2-6 (10-500 Hz, 2 g acceleration), impact resistance level IEC 60068-2-27 (5 g, 11 ms)

Protection level

Module body IP30, wiring terminal IP40, dustproof and anti small particle intrusion (suitable for semiconductor clean rooms)

Isolation performance

1000 VAC electrical isolation between input channel and power supply, 500 VAC isolation between channels, anti common mode interference voltage ≥ 1000 V

(3) Communication and compatibility parameters

Communication interface

1 high-speed synchronous serial interface (100 Mbps for real-time data exchange with PM861K01), 1 RS485 interface (supporting Modbus RTU for configuration and diagnosis)

Data transmission delay

Communication delay with PM861K01 ≤ 1 μ s, ensuring no lag in control instructions

Software compatibility

Supports ABB Precision Control Studio V3.0 and above (dedicated configuration software), compatible with Control Builder M V7.0 (plugin required)

Expansion capability

Single PM861K01 supports up to 8 parallel 128877-103 modules, achieving 64 high-precision acquisition channels and 16 pulse feedback channels

Core performance advantages

Millivolt level acquisition and micrometer level control accuracy: With an acquisition accuracy of ± 0.001% of full scale, it can distinguish 0.1 μ V weak signals (such as small changes in semiconductor wafer temperature) within a range of ± 10 mV. With a 10 μ s control cycle and sliding mode variable structure control algorithm, it achieves a positioning accuracy of ± 1 μ m for precision displacement tables (conventional modules only ± 10 μ m), meeting the requirements of ultra precision scenarios such as optical lens alignment and semiconductor lithography.

Multi signal collaboration and anti-interference design: 8 differential input channels support simultaneous acquisition of voltage, current, and resistance signals (such as temperature, pressure, and displacement signals), with 500 VAC isolation between channels to avoid signal crosstalk; 1000 VAC high isolation and 1000 V anti common mode interference capability enable stable operation in strong electromagnetic environments (such as RF equipment) in semiconductor workshops. The fluctuation of collected data is ≤ 0.002%, far superior to the 0.1% fluctuation of conventional modules.

Complex algorithms and custom control logic: The built-in Kalman filter algorithm can effectively filter out noise in weak signals (such as high-frequency interference from grating ruler feedback signals), improving the signal-to-noise ratio by 30 dB. It supports C language custom control logic and can develop exclusive precision control algorithms (such as dynamic focus control for laser cutting), suitable for high-end manufacturing scenarios with high customization.

High speed communication and low latency interaction: The communication delay between the 100 Mbps high-speed serial interface and PM861K01 is ≤ 1 μ s, ensuring that there is no lag in the issuance of control instructions and the upload of feedback data (such as real-time position correction for precision machine tools); Compared to the millisecond level industrial Ethernet communication of CI853-1, it is more suitable for the demand of "microsecond level synchronization" in ultra precision control.

Compact design and clean environment adaptation: IP30 protection and ultra-thin size (35 mm wide), can be installed inside precision equipment in semiconductor cleanrooms (Class 100) without the need for additional protective covers; Low power (≤ 3 W) design reduces temperature interference from module heating to surrounding precision sensors (such as infrared thermometers), ensuring stable acquisition accuracy.

Typical application scenarios

Semiconductor wafer lithography process control:

In the 7nm wafer lithography equipment, the 128877-103 module collects the wafer cone temperature (Pt1000, accuracy ± 0.001 ℃), lithography lens displacement (laser interferometer, ± 10 mV signal corresponds to ± 1 μ m displacement), and vacuum chamber pressure (capacitive sensor, 4-20 mA) through 8 differential inputs; The built-in sliding mode control algorithm dynamically adjusts the heating power of the wafer stage according to temperature changes, with a control cycle of 10 μ s, ensuring that the temperature fluctuation of the wafer stage is ≤± 0.005 ℃, and avoiding the offset of the lithography pattern caused by temperature drift; By exchanging data with PM861K01 through a high-speed serial interface, PM861K is then connected to the main control system of the lithography machine through the PROFINET IRT interface of CI853-1, achieving precise collaboration throughout the entire process.

Dynamic balance control of precision machine tool spindle:

On a five axis precision milling machine, the 128877-103 module collects feedback from the spindle grating ruler through two pulse inputs (each pulse corresponds to 0.1 μ m displacement), and collects spindle vibration (acceleration sensor, ± 100 mV signal), bearing temperature (Pt1000), and cutting force (strain gauge, ± 10 mV signal) through eight analog inputs; The Kalman filter algorithm filters out vibration signal noise, and the adaptive PID algorithm adjusts the spindle servo motor current in real-time based on displacement deviation (control accuracy ± 0.1 mA), controlling the spindle radial runout to ≤ 2 μ m, far superior to the 5 μ m standard of conventional machine tools; The 1 μ s low latency communication between the module and PM861K01 ensures real-time correction of dynamic errors during the cutting process, improving the machining accuracy of aerospace components.

Optical equipment laser focusing control:

In the laser marking machine, the 128877-103 module collects laser power (photoelectric sensor, ± 1 V signal, accuracy ± 0.001 V), worktable displacement (linear encoder, pulse signal), and ambient temperature (Pt1000); Custom C language control logic adjusts the laser power supply voltage based on power deviation (millivolt level adjustment), while correcting the focusing lens position based on displacement feedback (± 1 μ m positioning) to ensure that the marking pattern accuracy is ≤ 5 μ m; By communicating with the CI853-1 module through the RS485 interface, the laser power and displacement data are uploaded to the MES system, achieving full parameter traceability of the marking process and adapting to the precision marking requirements of electronic components.

Medical equipment precision fluid control:

In the hemodialysis machine, the 128877-103 module collects dialysate flow rate (electromagnetic flowmeter, 4-20 mA, accuracy ± 0.002%), temperature (Pt1000, ± 0.001 ℃), and pressure (pressure sensor, ± 100 mV); The fuzzy PID algorithm adjusts the peristaltic pump speed based on flow deviation (control accuracy ± 1 rpm) to ensure a stable dialysate flow rate of 500 mL/min ± 0.1 mL/min; The high isolation design of the module avoids the impact of electrical interference on medical equipment, complies with the IEC 60601 medical safety standard, and ensures the safety and reliability of the dialysis process.

Selection and usage precautions

(1) Key selection points

Select based on accuracy and signal type:

If millivolt level acquisition (such as ± 10 mV sensors) or micrometer level control (such as grating scale feedback) is required, priority should be given to 128877-103; If it is a conventional accuracy (± 0.1 ℃/± 1%), TC820-1 or PM820-1 can be selected to reduce costs.

When processing pulse feedback (such as encoders, grating rulers) and analog signals simultaneously, the 2-channel pulse input of 128877-103 is a necessary configuration, and conventional modules do not have this function.

Confirm the environment and power supply requirements:

The fluctuation of working temperature should be controlled within ± 0.5 ℃ (such as in semiconductor clean rooms), otherwise a constant temperature control cabinet is required; High precision regulated power supply (ripple ≤ 10 mVp-p) is required for power supply to avoid power supply noise affecting acquisition accuracy.

Software and system compatibility:

Precision Control Studio V3.0 specialized software (Control Builder M for regular modules) needs to be installed. If it needs to work with PM861K01, V7.0 or higher version plugins need to be installed to ensure algorithm parameters are synchronized with the main CPU.

(2) Installation and wiring precautions

Installation environment requirements:

Installed in a location away from heat sources (such as power modules) and strong electromagnetic sources (such as frequency converters), with a distance of ≥ 1 meter from interference sources; The installation of clean workshops requires the use of anti-static trays, with module grounding resistance ≤ 1 Ω (separately grounded, not shared with power ground); Reserve a 20mm gap between modules to avoid heat dissipation affecting surrounding precision sensors.

Wiring specifications:

Signal wiring: Use twisted pair shielded wires (wire diameter ≥ 0.5 mm ², single ended grounding of shielding layer), with a millivolt level signal cable length ≤ 5 meters to avoid signal attenuation; Pulse signals (such as grating rulers) require the use of dedicated differential signal lines, with 120 Ω terminal resistors installed at both ends.

Power wiring: Double core shielded wire (cross-sectional area ≥ 1 mm ²) is used, connected in series with a 1A fast fuse, and the positive pole of the power supply is connected in series with a 0.1 μ F filtering capacitor (near the module end) to reduce power ripple.

Isolation requirement: The module should be grounded and insulated from the equipment casing (using insulation gaskets) to avoid interference from ground current on weak signal acquisition.

(3) Key points for use and maintenance

Parameter configuration optimization:

Set the input signal range according to the sensor range (such as ± 10 mV range for micrometer level displacement) to avoid wasting accuracy due to excessive range; The control cycle is set according to the system response requirements (such as 10 μ s for lithography equipment and 100 μ s for conventional equipment), balancing accuracy and resource utilization; The parameters of Kalman filter need to be adjusted according to the characteristics of signal noise (such as increasing the filtering coefficient for high-frequency noise).

Regular calibration and maintenance:

Use a standard signal generator (such as a precision voltage source, with an accuracy of ± 0.0001%) to calibrate the input channel every month. If the deviation exceeds ± 0.002% of the full scale, zero and gain correction must be performed through software; Clean the module wiring terminals quarterly (using a dry and dust-free cloth), and check if the shielding layer grounding is reliable.

Test the isolation performance every six months (using a shaking table to measure the input power isolation resistance ≥ 100 M Ω) to ensure anti-interference ability; Replace the filtering capacitor and shielding cable annually to avoid accuracy degradation caused by aging.

Fault handling and data backup:

If the collected data fluctuates too much, priority should be given to checking the power supply ripple and grounding; If the control accuracy decreases, check the sensor calibration status and algorithm parameters; Regularly backup control algorithms and parameter configurations (stored on encrypted USB drives), and ensure consistent firmware versions when replacing modules to avoid compatibility issues.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-