YOKOGAWA CENTUM VP Integrated Production Control System

YOKOGAWA CENTUM VP Integrated Production Control System

Overview

The General Overview Manual for Yokogawa Electric's CENTUM VP Integrated Production Control System (Document Number: TI 33J01A10-01EN) is the 4th edition released in 2016, which provides a detailed introduction to the system's core concepts, configuration architecture, functional characteristics, engineering environment, and full lifecycle support. As the 8th generation CENTUM series product, CENTUM VP is the core platform of Yokogawa VigilantPlant solution, designed for control and management of multi industry factories, with high reliability, openness, and flexible scalability.

Core philosophy and core advantages

(1) Core concept

Build a full value chain operation support system around the three dimensions of "See Clearly, Know in Advance, Act with Agility":

See Clearly: Real time capture of factory wide data, precise push of key information, reducing information overload and blind spots;

Know in Advance: Integrate historical, real-time, and predictive data to support rapid and intelligent decision-making, and mitigate operational risks;

Act with Agility: Accelerate task collaboration, automate best practices, enhance production flexibility and bottleneck prediction capabilities.

(2) Core advantages (by role/scenario)

Description of core advantages of applicable objects/scenarios

Unified control/security/asset intelligence interface by operators to avoid information overload; Continuous Systematic Best Operating Practices

The integrated engineering environment of Engineer AD Suite supports flexible design, and the control application and I/O configuration can be independently adjusted

Controller performance 99.99999% availability, dual redundancy design, fault free instantaneous switching, supports N-IO software configurable I/O

Production management is compatible with S95/B2MML standards, achieving MES/enterprise system integration; Built in network security authentication

Maintenance personnel upgrade and modify online without any single point of failure; 40 year downward compatibility, protecting long-term investments

Integrated solution for project implementation (DCS/SIS/PIMS, etc.) to reduce integration risks and accelerate project delivery

System configuration and core components

(1) Overall architecture

The system is centered around "HIS+FCS+control network" and supports full-scale deployment from small to super large (1 million tags). It can integrate security systems, third-party devices, and remote sites to form a unified control ecosystem.

(2) Key component description

core component

HIS (Human Interface Station): Based on Windows system, supports desktop/open/closed consoles, compatible with 16:10/4:3 displays, multiple HIS mutual backup without single point of failure;

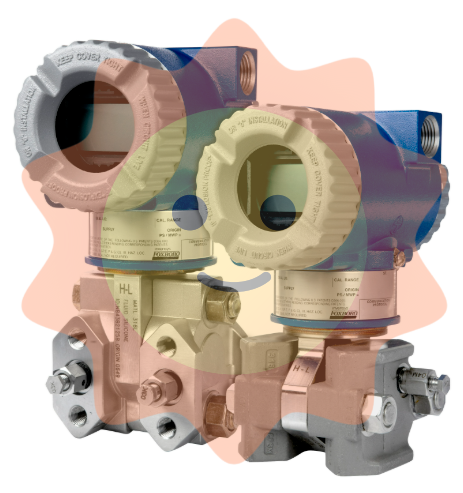

FCS (Field Control Station): independently developed by Yokogawa, supporting cabinet/rack installation, equipped with dual redundant processors, power and I/O modules, supporting online maintenance and remote deployment (IEC Zone 2/Class I Div. 2);

Control network (Vnet/IP): 1Gbps redundant Ethernet, compliant with IEEE802.3 standard, supports 5ms full network time synchronization, ensuring deterministic communication.

Auxiliary components

ENG (Engineering Station): Install AD Suite engineering software, supporting modular/non modular engineering design;

Gateway station (GSGW/USGS/BIOS): GSGW is used for subsystem monitoring, UGS/UGS2 integrates STARDOM/PLC, SIOS connects to third-party PCS (OPC interface);

Communication relay devices: BCV (connecting old CENTUM system), AVR (interconnecting Vnet/IP and V net), WAC Router (connecting Vnet/IP domains across WAN).

integrated system

ProSafe-RS: T Ü V SIL3 certified safety instrumented system, supporting ESD/PSD/F&G/BMS functions, sharing operating environment with CENTUM VP to achieve integrated safety and control;

Digital fieldbus: supports mainstream protocols such as Foundation fieldbus, HART, PROFIBUS-DP, Modbus TCP/IP, ISA100.11a, etc;

Third party integration: Through OPC DA/A&E interface, data exchange with third-party PCS and ERP systems is achieved.

Detailed explanation of core functions

(1) Engineering Features (AD Suite)

AD Suite is an integrated engineering environment added to CENTUM VP R6, supporting full lifecycle engineering management. Its core functions are divided into standard and optional features

Function type, specific function, core value

The standard function non modular project first determines the hardware configuration, and then carries out engineering design on a hardware by hardware basis

History management automatically saves engineering change records, supports traceability and retrieval

AD Server centrally manages engineering data and projects, supports backup/recovery

Optional modular engineering reuse design modules (control logic/alarm attributes, etc.) to improve efficiency and consistency

Batch editing and modification of multiple module parameters, supporting consistency verification

Change control is managed through ModPack to manage the change process, recording test results and responsible parties

Dependency analysis analyzes the correlation between control logic/I/O/graphic labels and evaluates the impact of changes

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com