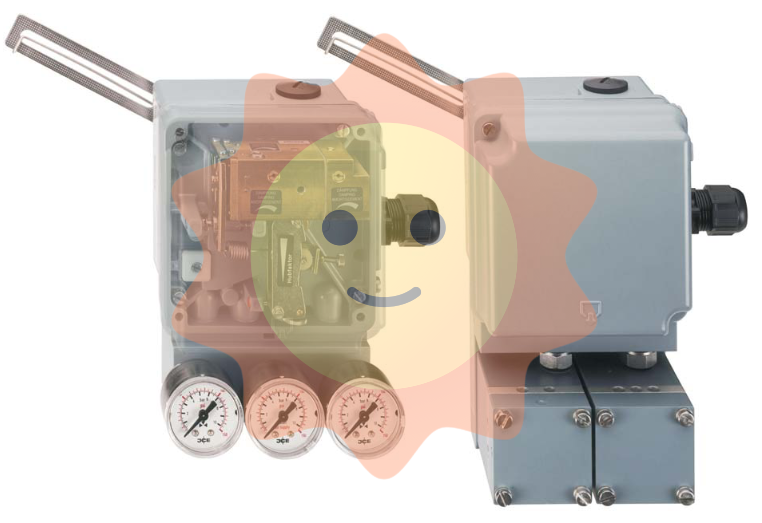

ABB IOR810N200 Mounting Base for IOR-810

Basic Introduction

The ABB IOR810N200 Mounting Base for IOR - 810 is a mounting base specifically designed for IOR - 810 equipment. It provides a stable mounting platform for the IOR-810 and ensures that the unit is installed and operates correctly in all environments.

Functional Features

Solid mounting support

Precise fit: This mounting base is custom designed to fit the dimensions and mounting requirements of the IOR-810 unit. It precisely matches the bottom or side mounting ports of the IOR-810, ensuring that the unit is mounted in the exact position it needs to be, without wobbling or shifting. For example, the mounting holes are positioned and sized to exactly match the fixing holes of the IOR-810 unit, allowing the unit to be securely fixed to the base.

High mechanical stability: It is made of robust materials, usually metal (e.g. aluminum alloy or steel plate), with sufficient strength and rigidity. This allows it to withstand the weight of the IOR - 810 device and effectively protects the device from damage in the event of an external shock, such as a minor bump or vibration. For example, in industrial environments where there may be vibrations caused by the operation of machinery, the mounting base absorbs these vibrations and prevents them from adversely affecting the IOR-810 equipment.

Convenient Mounting Options

Multiple Mounting Options: A variety of mounting options are supported to suit different usage scenarios. It can be screwed to a desktop, cabinet mounting panel, wall, or other flat surface. For example, in a laboratory environment, it can be fixed on a lab benchtop; in an industrial control cabinet, it can be mounted on the internal panel of the cabinet for easy integration with other equipment.

Easy to operate: The installation process is simple and easy. Users only need to place the IOR - 810 device on the base, align the mounting holes, and then use the matching screws and other fixed parts to fix the device. This simple installation does not require complex tools or specialized installation skills, reducing installation time and costs.

Environmental adaptability

Good protection: With a certain degree of protection, it can protect the IOR - 810 equipment from the surrounding environment. For example, it prevents the bottom of the device from coming into direct contact with wet floors or being exposed to dust. In harsh industrial environments, such as those where corrosive gases or liquid splashes are present, the mounting base acts as a first line of defense, isolating the equipment from harmful environmental factors.

Temperature adaptability: able to maintain stable performance over a wide temperature range. The materials used will not be significantly deformed or damaged due to temperature changes, ensuring that IOR-810 equipment can be installed and work properly in different temperature conditions (such as low-temperature refrigerated warehouses or near high-temperature industrial furnaces).

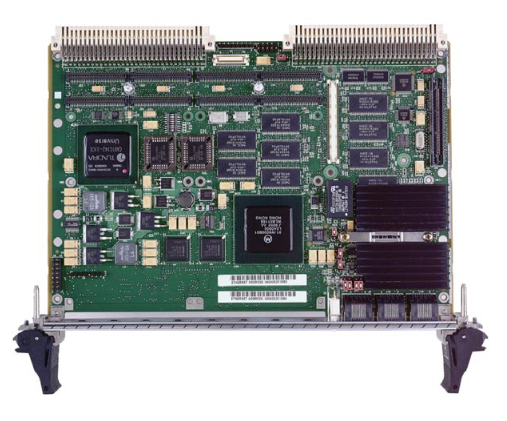

Technical data

Physical parameters

Dimensions: The dimensions are adapted to the IOR-810 equipment, depending on the size of the IOR-810. For example, the length may be between 200 - 500mm, the width between 100 - 300mm and the thickness between 10 - 50mm, these dimensions are to ensure stable support of the equipment and ease of installation.

Weight: Medium weight, typically between 1 - 5kg depending on material and size. Lighter weights allow for easier installation and handling, while heavier sections increase stability.

Material Characteristics: If it is made of metal, such as aluminum alloy, it has good electrical and thermal conductivity and corrosion resistance; if it is made of steel plate, it has high strength and hardness. The surface of these materials may be specially treated, such as spraying anti-corrosive paint, galvanizing, etc., to further improve its protective performance.

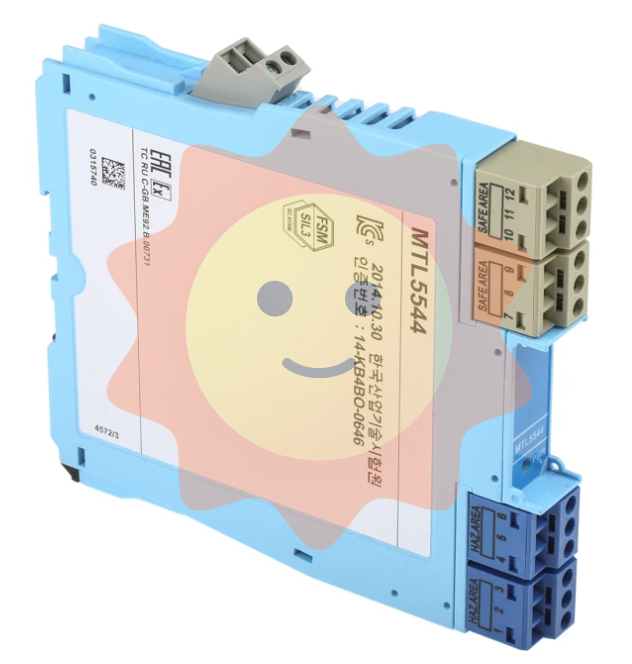

Installation Parameters

Mounting Hole Positions and Sizes: The positions and sizes of the mounting holes are designed according to the fixing requirements of the IOR-810 equipment. The holes are typically spaced between 50 - 200mm apart, with a hole diameter of 3 - 8mm, and are capable of being mounted using standard screws or bolts.

Mounting compatibility: In addition to screw mounting, other mounting methods may be supported, such as snap-in mounting (if designed with the appropriate snap-in construction) or rail mounting (in specific cabinet systems). This compatibility allows it to be used flexibly in a variety of installation environments.

Application Scenarios

Industrial automation

Control cabinet mounting: In industrial automation control cabinets, as a mounting base for IOR-810 devices (possibly controllers, drives, etc.). After mounting the device on the base, the base is then fixed to the internal panel of the control cabinet, which facilitates the wiring and connection of the device to other electrical components (e.g., PLCs, sensors, actuators, etc.), as well as the maintenance and replacement of the device.

Production Equipment Integration: On industrial production equipment (e.g. machine tools, automated production lines), it is used to mount the IOR - 810 device so that the device can be better integrated with the control system of the production equipment. For example, in a robot control cell in an automotive manufacturing line, the mounting base ensures that the IOR-810 device (which may be a component of the robot controller) is stably mounted in the robot's control cabinet, guaranteeing precise control of the robot.

Laboratory and test environments

Bench mounting: In the laboratory, the mounting base is fixed to the bench top for mounting the IOR-810 device for experimentation and testing. For example, in an electronics test lab, where the IOR-810 device may be part of the test instrumentation, the mounting base ensures that the test instrumentation is stable on the lab bench, allowing for easy manipulation and observation by the researcher.

Test System Integration: In complex test systems, a mounting base can help integrate the IOR-810 unit with other test equipment such as signal generators, oscilloscopes, etc. The IOR-810 unit can also be integrated with other test equipment. By mounting the IOR - 810 equipment on the base and then placing the base in a suitable location, signal transmission and cooperative work between the equipment can be better realized, improving the efficiency and accuracy of the test system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com