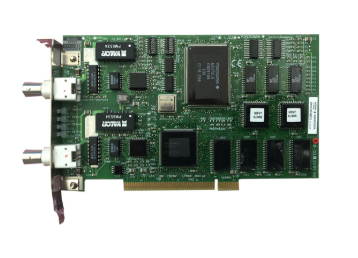

The Alstom MDEX1 microprocessor control board is a high-performance embedded control module designed by Alstom specifically for industrial automation control systems, rail transit traction systems, and core control of power equipment. This product is centered around a high-performance microprocessor, integrating multi-channel signal acquisition, high-precision computing processing, multi protocol communication interfaces, and security control logic. It undertakes core control responsibilities such as system instruction parsing, operation status regulation, and fault diagnosis and warning. It has core advantages such as fast computing speed, high control accuracy, stable and reliable operation, and strong environmental adaptability. It can provide precise and efficient control guarantees for equipment and systems in complex industrial conditions, and is the core control component in Alstom's high-end automation equipment and large-scale industrial systems.

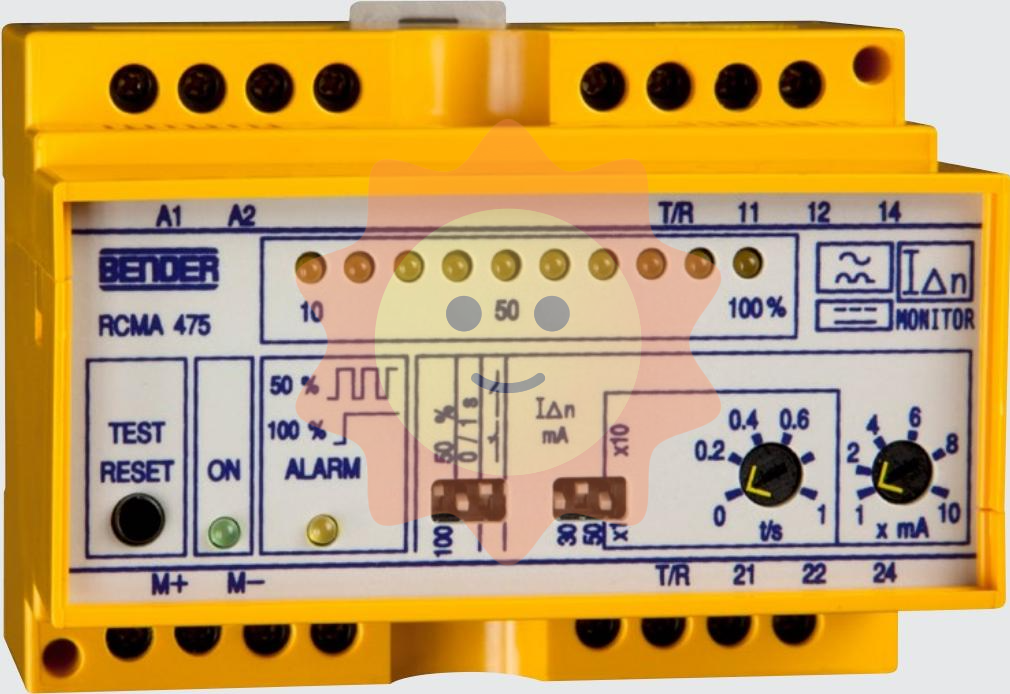

Alstom MDEX1 microprocessor control board

Product Overview

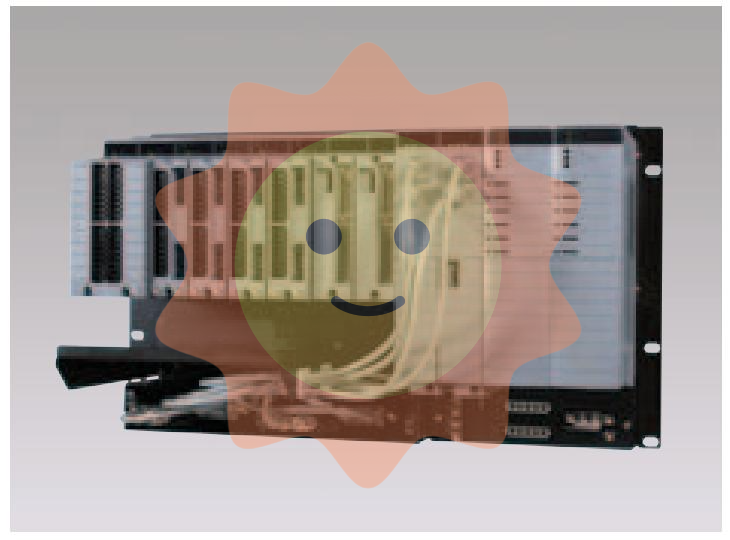

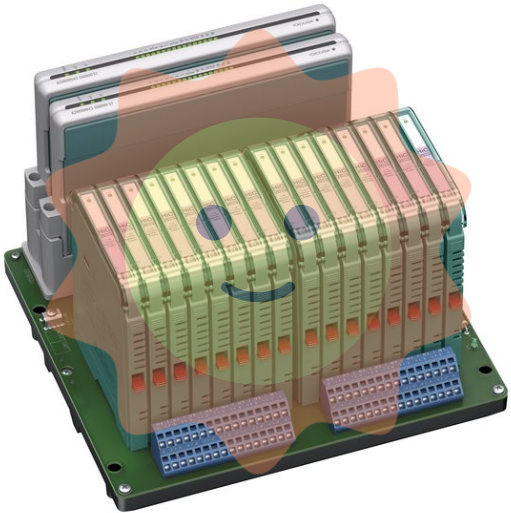

The Alstom MDEX1 microprocessor control board is a high-performance embedded control module designed by Alstom specifically for industrial automation control systems, rail transit traction systems, and core control of power equipment. This product is centered around a high-performance microprocessor, integrating multi-channel signal acquisition, high-precision computing processing, multi protocol communication interfaces, and security control logic. It undertakes core control responsibilities such as system instruction parsing, operation status regulation, and fault diagnosis and warning. It has core advantages such as fast computing speed, high control accuracy, stable and reliable operation, and strong environmental adaptability. It can provide precise and efficient control guarantees for equipment and systems in complex industrial conditions, and is the core control component in Alstom's high-end automation equipment and large-scale industrial systems.

As an industrial grade core control unit, the MDEX1 microprocessor control board strictly follows international industrial control standards and Alstom's strict quality control specifications, adapts to various harsh operating environments, and is widely used in fields such as rail transit, power plants, and industrial manufacturing that require high control accuracy and reliability. It provides core computing power and control support for the intelligent and automated operation of the system.

Core functions

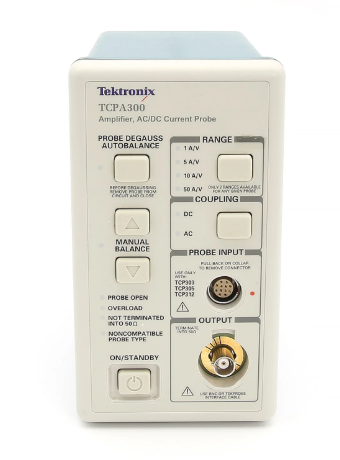

1. High precision data acquisition and processing

Integrating multi-channel high-precision analog signals (such as 4~20mA, 0~10V) and digital acquisition interfaces, it can real-time collect various state parameters (such as current, voltage, temperature, pressure, position, etc.) during system operation. Equipped with a high-performance 32-bit microprocessor, it has high computing frequency and strong data processing capability, which can quickly complete complex control algorithm operations, logical judgments, and instruction generation, ensuring the real-time and accuracy of control instructions.

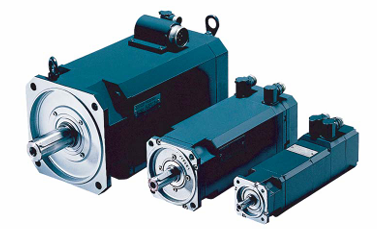

2. Multi mode precise control and logical regulation

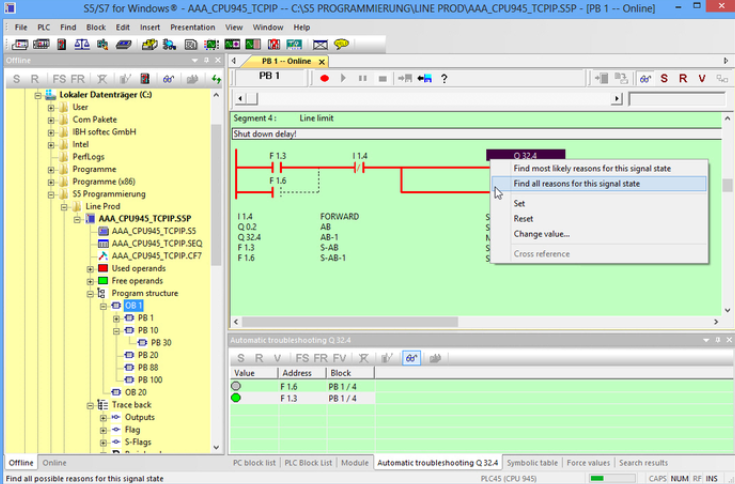

Supports multiple control modes such as position control, speed control, torque control, etc., and can be flexibly switched according to different application scenarios; Built in standardized control logic module, while supporting users to customize control strategies through dedicated development software, adapting to diverse device control requirements. Having precise closed-loop control capability, through real-time feedback adjustment, ensuring that equipment operating parameters are stable within the set range, improving control accuracy and operational efficiency.

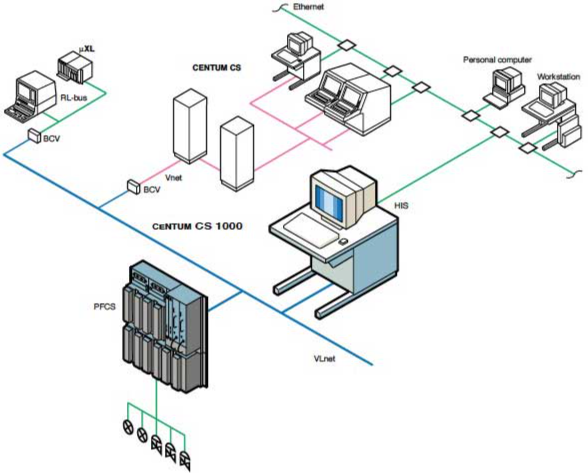

3. Multi protocol communication and system collaborative interconnection

Built in various mainstream industrial communication interfaces and protocol processing units such as CANopen and EtherCAT, it can achieve high-speed data exchange with upper monitoring systems, lower actuators, sensors, and other control modules. Supporting the construction of distributed control networks, it can serve as the core node in the control network to achieve multi device collaborative control, improving the overall system's collaborative operation efficiency and scalability.

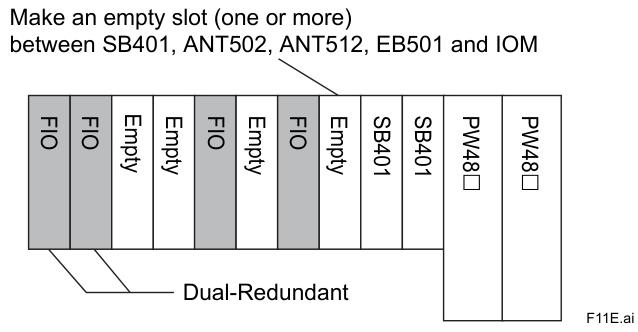

4. Fault diagnosis and safety protection under all operating conditions

Equipped with full operating condition monitoring and fault diagnosis functions, it can detect various abnormal operating conditions such as circuit faults, signal abnormalities, overload, overheating, overvoltage, etc. in real time, quickly trigger fault alarms, and record fault information. Built in redundant safety control logic and hardware protection circuits can promptly execute protective actions such as safe shutdown and emergency braking in the event of a fault, minimizing fault losses and ensuring the safety of equipment and personnel.

5. Flexible configuration and remote operation and maintenance management

Support control parameter configuration, control logic debugging, and program upgrading through dedicated software, with offline programming and online debugging functions, suitable for on-site debugging and later system upgrade requirements. Supporting remote communication and status monitoring, operation and maintenance personnel can remotely obtain equipment operation data and fault information, achieve remote diagnosis and parameter optimization, and reduce operation and maintenance costs and on-site workload.

Key technical parameters

Product Model

Alstom MDEX1

Product Type

Industrial grade microprocessor control board (embedded core control module)

Core processor

32-bit high-performance microprocessor, operating frequency ≥ 150MHz

storage capacity

Program memory ≥ 256KB, data memory ≥ 64KB

Signal acquisition channel

Analog input: 8 channels (12 bit AD conversion, accuracy ≤ ± 0.1% F.S); Digital input: 16 channels

Control output channel

Digital output: 8 channels (maximum load current 3A); PWM output: 4 channels (adjustable frequency, accuracy ≤± 0.5%)

communication interface

1 CANopen 2.0B, 1 EtherCAT, 1 RS485 (Modbus RTU)

power supply parameters

DC 24V (typical value), operating voltage range: DC 18~32V; Rated power consumption ≤ 10W

Working temperature range

-30 ℃~+70 ℃ (no condensation, no freezing)

Storage temperature range

-40 ℃~+85 ℃ (no condensation, no freezing)

relative humidity

≤ 95% (non condensing)

Protection level

IP20 (terminal section); IP30 (main body of the board)

Electromagnetic compatibility standards

Compliant with DIN EN 61000-6-4 (emission) and DIN EN 61000-6-2 (immunity) standards

Installation method

DIN rail installation or screw fixed installation (compliant with IEC 60715 standard)

connection method

Screw terminal connection, compatible with wire specifications: 0.2~2.5mm ² (rigid/flexible)

Dimensions (length x width x height)

Approximately 120mm x 100mm x 50mm (excluding terminals and installation components)

Product advantages

-Efficient computation and precise control: Equipped with a high-performance 32-bit microprocessor, it has fast computation speed and strong data processing capability. Combined with high-precision signal acquisition and closed-loop control logic, it has high control accuracy and fast response, ensuring stable and efficient operation of the equipment.

-Communication compatibility and strong collaboration: integrating multiple mainstream industrial communication protocols and interfaces, supporting distributed control network construction, can achieve seamless collaborative interconnection with multiple devices and systems, and enhance system integration and scalability.

-Safe and reliable, comprehensive protection: equipped with full condition fault diagnosis and redundant safety protection functions, dual hardware and software protection, can effectively respond to various abnormal working conditions, maximize equipment and personnel safety, and reduce fault losses.

-Flexible configuration, convenient operation and maintenance: supports custom control strategies and remote operation and maintenance management, adapts to diverse application scenarios, while reducing on-site debugging and later operation and maintenance costs, and improving operation and maintenance efficiency.

-Industrial grade design, excellent environmental adaptability: strictly following industrial grade design standards, wide temperature working range, high protection level, can operate stably for a long time in harsh industrial environments such as high and low temperatures, high humidity, and strong electromagnetic interference, with long service life and low failure rate.

Application scenarios

The Alstom MDEX1 microprocessor control board, as an industrial grade core control component, is widely used in fields with strict requirements for control reliability and accuracy due to its high-precision control capability and stable operating performance. Typical scenarios include:

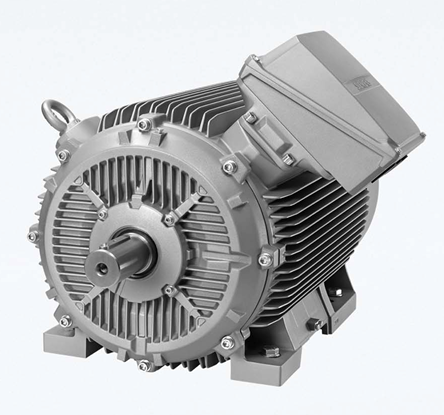

1. In the field of rail transit: traction control system, braking control system, door control unit, core control of onboard monitoring system for subway and high-speed rail;

2. Power industry: core control modules for automation monitoring systems, relay protection devices, and generator speed control systems in power plants and substations;

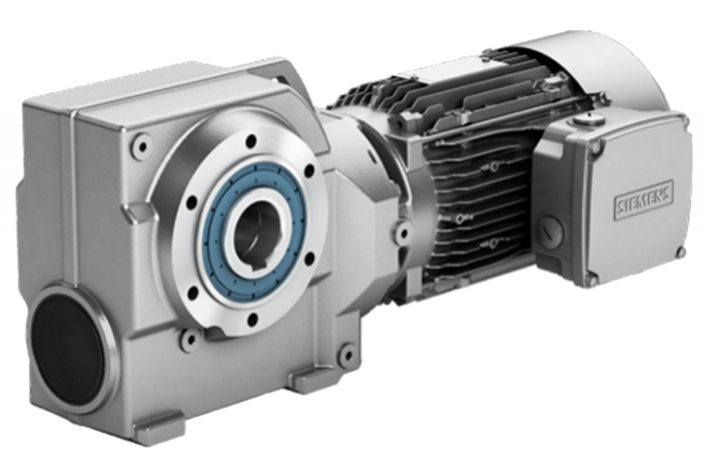

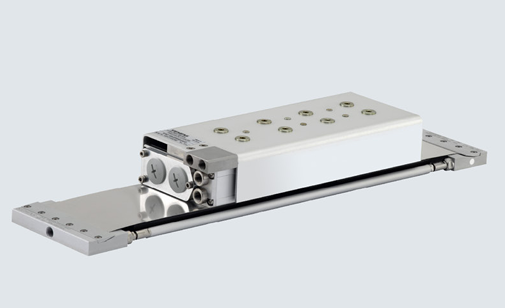

3. Industrial automation: transmission control systems for production lines, precision machining equipment control units, and robot motion control systems in industries such as metallurgy, chemical engineering, and cement;

4. Intelligent manufacturing: Equipment collaborative control network for intelligent factories, precision control system for production processes, and control units for intelligent warehousing and logistics equipment;

5. Other industrial scenarios: control systems for large industrial pumps/fans, control units for special equipment (such as lifting equipment, elevators), control modules for new energy equipment (such as photovoltaic inverters, wind power converters).

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com