Find the hidden champion of Chinese textile materials

1 History of the global textile industry: transformation to high value-added materials with a deep industrial foundation

Textile material industry chain sorting: top-down from heavy assets to heavy manpower, differentiated textile materials with high added value

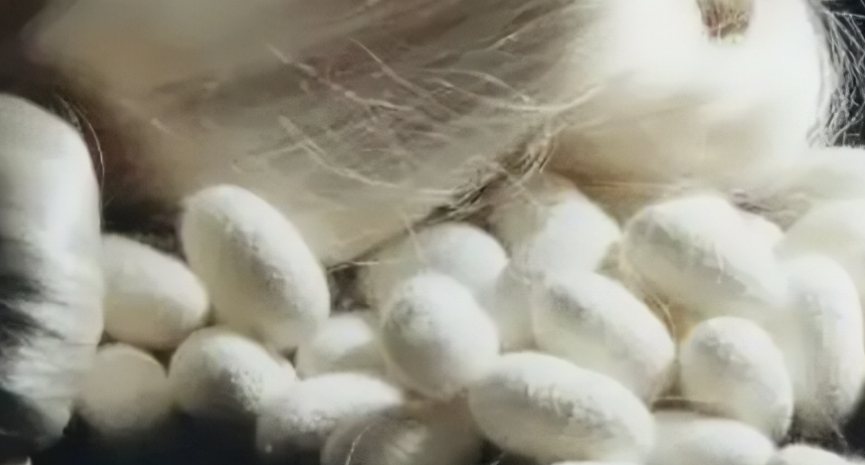

The initial product of clothing is yarn, which is twisted from textile fibers. Textile fibers are generally divided into chemical fibers and natural fibers according to the raw materials and processes required for the production process, of which chemical fibers are divided into synthetic fibers and man-made fibers. Natural fiber is directly composed of natural material cotton and hemp hair silk, artificial fiber is first processed by cotton wool, wood, acetic acid and other natural raw materials to form the corresponding cellulose and then synthesized, synthetic fiber is first produced by petroleum refining various chemicals and then synthesized by chemical reaction. Yarn is woven and dyed to form different kinds of fabrics, including synthetic fabrics, human fabrics, natural fibers and blended fabrics made of different kinds of yarns. At the same time, the accessories mainly include zipper buttons, etc., which are produced according to the design needs of the garment, and are matched with accessories in the fabric cutting and sewing to finally form the garment.

From the perspective of all links of the industrial chain, terminal processing such as clothing tends to be labor-intensive industries, with greater demand for manpower and low added value. The differentiated functions of clothing, such as sweat absorption, breathability, warmth, waterproof, etc., are mainly provided by yarn and fabric, so the development of differentiated yarn and fabric requires higher research and development ability of manufacturers, and accessories also have a greater impact on the appearance and functionality of clothing. In general, the industrial chain is bottom-up, the higher the equipment and capital requirements, the less the demand for manpower, and the differentiated yarn, fabric and other textile materials that have a greater impact on the functionality of the end product have higher added value.

Global textile industry recovery: a hundred years of history, five rounds of migration, accompanied by the upgrading of industrial structure

From the perspective of the migration sequence of various links, industries such as clothing that are biased towards terminal processing and have labor-intensive attributes migrate first, then migrate to low value-added textile production capacity, and finally achieve industrial transformation and upgrading, focusing on high-end manufacturing and technology research and development. From the current situation, China's textile industry continues to dominate the global leadership, to achieve the vertical extension of the industrial chain, high value-added industrial chain links are booming, low value-added terminal processing links are overflowing Southeast Asia.

1) Late 19th century to early 20th century: originated in the United Kingdom, migrated to the United States after the First World War, where labor and resources are rich

The outbreak of the first industrial revolution, the textile industry originated in the United Kingdom, in 1851, 60% of the British cotton textile exports to the world, accounting for 40% of the total domestic exports, in 1890, the British cotton yarn production of 42.4 million ingots (the United States/Japan only 14/280 million ingots), At the end of the 19th century, the raw material cotton of the British cotton industry was mainly imported from the Indian colonies, which had the comparative advantage of low cost. However, with the outbreak of the First World War, British exports fell into a downturn, coupled with the relative lack of labor costs and raw materials, cotton textile industry production gradually by the labor sufficient and resource-rich United States, in the 1920s, the United States cotton yarn production accounted for more than 50% of the world.

At the same time as the booming textile industry, clothing accessories as an accompanying industry came into being, the first clothing accessories to buttons, mainly used for "clothing closure", 1893 American Vitcon Judson applied for "mobile button", the formal prototype of modern zipper, but this invention was not paid attention to at first. It was not commercially available until 1918, when it was modified by the Swede Senbeck. Until the 1920s during the First World War, the United States Goodrich Company bought the patent of the zipper and began large-scale commercial, since the zipper due to its convenience and similar functionality with buttons, quickly replaced the status of buttons.

2) 1930~1975: Europe and the United States pioneered and completed the transformation of synthetic fiber, Japan became an export power, and the garment segment moved to the port of South Korea and Taiwan in the late 60s

In fact, at the end of the 19th century, Japan has begun to develop the textile industry, cotton yarn production reached 38.14 million ingots in 1920 (only 1.14 million ingots in 1900), with the promotion of scientific management model and textile equipment upgrading, Japan's cotton yarn industry labor production efficiency is higher than the United Kingdom and the United States. From 1910 to 1930, Japan undertook a large number of textile manufacturing from Western countries with low labor costs, and in 1925 Japan's textile industry exports accounted for 68.5% of the total domestic volume. During World War II, the Japanese textile industry was severely affected, and spinning and textile production did not get back on track until 1955. In the 1950s, Japan's low labor costs led to the partial transfer of global industry to Japan, and the textile industry in South Korea and Taiwan had just achieved self-sufficiency. The zipper industry also began the first big industrial transfer with this wave, and Japan began to replace the United States as the world's zipper manufacturing center.

In the 1960s, the export share of the textile industry in Western Europe and the United States continued to decline, but the transformation and upgrading of the textile industry was completed through the development of synthetic fibers and high-end equipment manufacturing. The growth of natural fibers and fabrics in Japan slowed down, and the textile industry continued to maintain the world's first leading position by promoting the development of chemical fibers in the late 1960s, but with the sharp rise in labor costs in Japan, Japan quickly transferred clothing production capacity to South Korea and Taiwan Port, from the share of clothing exports, Japan fell from 11% in 65 years to 2% in 75 years. Korea and Taiwan rose from 2 percent to 7-8 percent.

3) 1970-1995: Japan to high-end technology and manufacturing transformation, South Korea and Taiwan bear the export center, the beginning of 90s gradually peel off the garment link

With the rising labor costs in Japan in the late 1960s, South Korea and Taiwan, which had cheap labor and sufficient production conditions, gradually assumed the role of division of labor in the textile industry. In 1980, the share of Japan/South Korea/Taiwan textile industry exports was 6.8%, 6.2% and 5.1%. South Korea/Taiwan exports are dominated by natural fibers and garments (the share of South Korea's garments and cotton yarn exports is about 10%). At this time, the appreciation of the yen accelerated the contraction of the Japanese textile industry, and Japan transformed and upgraded its research and development of high-end fibers and fabrics. At the end of the 1980s, the share of South Korea's garment exports reached a peak, and the first place of Italy was basically the same, and then due to the rise of labor costs, the garment link has been migrated to China.

4) 1990-2015: Korea and Taiwan were looking for a way of transformation and upgrading, and China started from the garment link, and the textile industry quickly rose to the absolute lead

At the end of the 1990s, with the demographic dividend fading, Korea/Taiwan clothing, textile exports have declined. China's Taiwan began to develop capital-intensive upstream petrochemical raw materials, and South Korea learned from Japan's path to strengthen the development of high-end fibers and fabrics, advanced equipment investment and enhance clothing design capabilities, and transition to high value-added links. At the same time as the migration of the textile industry, the zipper manufacturing industry also began a second industrial transfer, and the zipper manufacturing center was moved from Japan to China. After the 21st century, under the double benefit of accession to the WTO and the abolition of the MFA agreement, the development of China's textile industry has ridden the dust, in 2015 textile/garment exports share of 37.8%/39.5%, while bearing 70% of the global synthetic fiber production.

5) 2010~ now: The rise of Southeast Asia, China has a trend of low-end capacity migration and rapid increase of high-end products

After 2010, China's labor cost has risen, and the labor cost is only 1/3 of China's emerging countries in Southeast Asia, which bear the terminal processing links such as clothing. In 2019, the export share of Vietnam/Bangladesh/India textile industry was 5.3%/4.6%/4.5% respectively, of which the share of apparel was 6.5%/6.6%/4.4% respectively. China has a trend of partial stripping of low-end links, the share of garment exports has fallen to 34.1%, and the export value of cotton fabrics has decreased by 11% from 2011 to now (synthetic fabrics have increased by 28%). At the same time, the proportion of China's high value-added products is also rapidly increasing, the proportion of special textiles in 2000 was only 4.2% (Japan/Korea/Taiwan about 18%), and reached 17.5% in 2019 (Japan/Korea/Taiwan 35%/18%/22%).

1780~1940: The origin of the textile industry, the United Kingdom, the United States, Japan has developed rapidly

The first industrial revolution opened the long river of the development of textile manufacturing industry, along with the process of industrial revolution, economic development stage and war, the textile industry in Britain, the United States, Japan has been rapid development, countries with production and trade to complete the initial capital accumulation.

United Kingdom: The first Industrial revolution in the 18th century contributed to the origin of the cotton spinning industry. In the 18th century, the textile industry originated in the United Kingdom, the invention of the steam engine in 1781 contributed to the first industrial revolution, bringing a steady stream of power to the textile industry, Britain imported cheap cotton raw materials from the Indian colonies, produced high-quality cotton products and exported to the world, cotton fabric successfully replaced wool and linen products to become the most popular fabric in Europe. For more than a century, the United Kingdom dominated the export of cotton products worldwide, and in 1851, the United Kingdom exported nearly 60% of its cotton textile products, accounting for 40% of all exports. Until the end of the 19th century, the British textile industry still accounted for half of the world's production capacity.

The United States: In the 19th century, the second Industrial Revolution promoted productivity progress, and the United States gradually replaced the United Kingdom as the global textile trade center. In the mid-19th century, the second Industrial Revolution brought electric power technology innovation to promote the rapid development of the textile industry in Europe and the United States, the United States with unique land resources and labor advantages to vigorously develop cotton planting and textile industry. The outbreak of the First World War led to a downturn in the export of British textile products, and the United States gradually replaced the United Kingdom as a global trade center. According to the statistics of the Australian Cotton Association, the United States in the 1920s accounted for more than 50% of the world's cotton yarn production.

Japan: The textile industry grew rapidly in the first half of the 20th century, and the industry was revitalized after World War II, and the added value was upgraded. In 1882, Mitsui Zaibatsu invested in the establishment of Osaka Textile Company as a sign, the government began to vigorously develop silk reeling and cotton spinning, in 1890, the output of cotton ingots in Japan was only 278,000 (in the same year, the output of cotton ingots in the United Kingdom was 42.4 million, and the output of cotton ingots in the United States was 14.4 million), and rapidly increased to 38.136 million in 1920. From 1910 to 1930, Japan undertook a large number of textile production from Western countries with the advantage of lower costs. In 1915, Japan's textile exports accounted for 43.1% of total exports, and in 1925, the export proportion was as high as 68.5%, becoming an important pillar of the national economy, of which raw silk and cotton silk accounted for 43%. In the industrial chain in the relatively upstream stage, according to the "Japanese textile Industry Centennial history and prospects", in 1933, Japan's cotton industry exports more than the United Kingdom. At the same time, Japanese cotton textile enterprises promote scientific management methods, and vigorously improve textile equipment, such as doubling the production process of the roving frame, and completing the super draft in the spinning frame, so that the draft ratio has been increased from 15 times to 30-50 times, and the production efficiency has been greatly improved. According to statistics, the labor production efficiency index of Japan's cotton yarn industry in 1933 (compiled according to the output of cotton yarn per hour of labor) reached 225, surpassing the 165/120 of the United States and the United Kingdom. The economic crisis and World War II affected Japanese exports, but the added value of products increased: from 1930 to 1945, affected by the Showa economic crisis and World War II, Japan's overall exports were impacted, of which textile exports fell faster, and the proportion of exports fell to 42% in 1940. In terms of the structure of export products, compared with raw silk and cotton silk, the proportion of higher value-added products such as textiles and textile machinery has been greatly increased.

1940~1970: The United States and Europe created synthetic fibers to complete the transformation, Japan grew, and South Korea and Taiwan started

The European and American textile industry migrated to East Asia, pioneered synthetic fibers, and completed the transformation of the industry to high-end manufacturing and technology; Japan with a better industrial base to follow the pace of Europe and the United States to develop synthetic fibers; Korea, Taiwan textile industry from import-based to self-sufficient and then export-oriented, on the one hand, quickly undertake the natural fiber from Japan, clothing links, on the other hand, China Taiwan in the cotton industry export restrictions, vigorously develop synthetic fiber business, product added value has advantages.

Europe and the United States: Pioneered synthetic fibers, the textile industry moved to East Asia and completed the transformation

Due to the rising labor costs in the United States and Europe, the textile industry gradually migrated to East Asia with cost advantages. According to statistics, in 1962, the share of textile exports in the United States/United Kingdom was only 8.3%/11.8%, and the share of clothing exports was only 6.0%/7.3%, which was significantly lower than that of Japan in the same period, and there is still a trend of continued decline. At the same time, the European and American textile industry is rapidly transforming and upgrading, on the one hand, the development of high-end manufacturing areas such as textile machinery, on the other hand, the creation of synthetic fibers, leading the change of the textile industry.

Europe and the United States created synthetic fiber, petrochemical industry to promote the industrialization of synthetic fiber, textile industry into a new era. In 1939, the United States DuPont Company realized the industrial production of nylon 66 fiber, in 1940, the German Farbon company realized the industrial production of nylon 6 fiber, and in 1953 and 1955, the United States DuPont and the United Kingdom ICI built polyester fiber production bases. Synthetic fiber has excellent performance and is not affected by the advantages of natural conditions, coupled with the rapid rise of the global petrochemical industry in the late 1950s to provide sufficient new raw materials for the synthetic fiber industry, synthetic fiber raw materials from coal and calcium carbide to stone oil and natural gas conversion, thus promoting the explosive growth of the global synthetic fiber industry. From 1950 to 1970, the production of synthetic fibers in the world increased from 69,000 tons to 4.7 million tons, and the textile industry gradually entered the era led by synthetic fibers. Due to the relatively difficult production technology and conditions of synthetic fibers at that time, the world's synthetic fibers were mainly concentrated in the United States, Western Europe and Japan three developed countries/regions, and the United States/Western Europe/Japan accounted for 32%/31%/21% of the global synthetic fiber production in 1970.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands