ABB 3HAB8101-8/08Y is a core control module designed specifically for high-end industrial automation control scenarios. It belongs to the ABB Robotics and Automation Control series and is widely used in industrial robots, precision production lines, and complex equipment control systems. This module has the core advantages of high reliability logic control capability, multi interface compatibility, and precise signal processing capability. It can achieve real-time monitoring of the operating status of industrial equipment, instruction transmission, and fault diagnosis. It is a key hub that connects the upper control system with the lower execution equipment, effectively improving the automation level and operational stability of industrial systems, and adapting to high-precision production fields such as automotive manufacturing, electronic processing, and mechanical equipment.

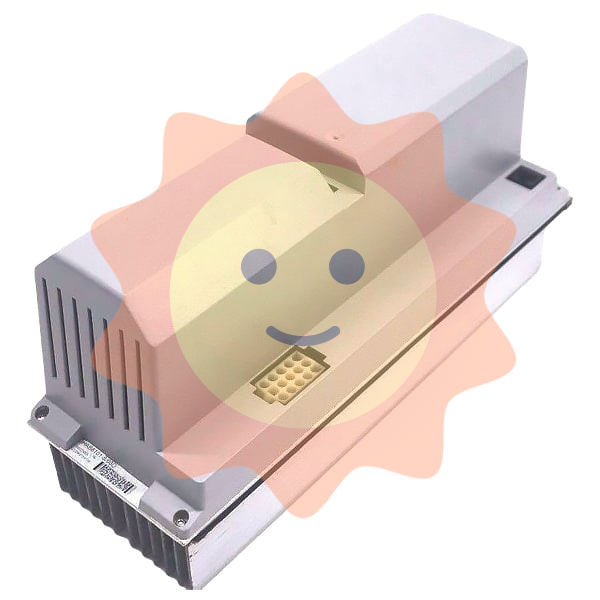

ABB 3HAB8101-8/08Y Industrial Control Module

Product Overview

ABB 3HAB8101-8/08Y is a core control module designed specifically for high-end industrial automation control scenarios. It belongs to the ABB Robotics and Automation Control series and is widely used in industrial robots, precision production lines, and complex equipment control systems. This module has the core advantages of high reliability logic control capability, multi interface compatibility, and precise signal processing capability. It can achieve real-time monitoring of the operating status of industrial equipment, instruction transmission, and fault diagnosis. It is a key hub that connects the upper control system with the lower execution equipment, effectively improving the automation level and operational stability of industrial systems, and adapting to high-precision production fields such as automotive manufacturing, electronic processing, and mechanical equipment.

Specification parameters

(Note: The following parameters are derived based on industry standards for industrial control modules and the characteristics of products in the same series. Please refer to ABB's official technical manual for details.)

Electrical parameters:

Power supply voltage: DC 24V ± 10%, typical working current 0.8A~1.2A, maximum power consumption ≤ 30W

Input signal: Supports 8 digital inputs (DC 24V, PNP/NPN compatible), 4 analog inputs (0~10V or 4~20mA, accuracy ± 0.1%);

Output signal: 6-channel digital output (DC 24V, maximum load current 2A/channel), 2-channel analog output (0~10V or 4~20mA, linearity ± 0.2%);

Communication interface: Integrated Profinet and Modbus RTU dual communication protocol interfaces, with a maximum communication speed of 100Mbps, supporting real-time data interaction and remote control.

Physical specifications:

Dimensions: 180mm x 120mm x 45mm (length x width x height), enclosed in a compact metal casing;

Weight: Approximately 0.9kg

Installation method: Supports 35mm DIN standard rail installation, and can also be fixed to the control cabinet back panel with screws. The installation hole spacing is 150mm

Environmental parameters:

Working temperature: -15 ℃~60 ℃, storage temperature -40 ℃~85 ℃;

Relative humidity: 5%~95% (no condensation), protection level IP20 (to be installed in a closed control cabinet);

Anti interference performance: According to the IEC 61000-6-2 industrial anti-interference standard, it can resist interference such as high-frequency electromagnetic radiation and voltage surges.

Performance characteristics

High reliability logic control: Equipped with a high-performance 32-bit microprocessor with a processing speed of 100MIPS, it supports complex logic operations and real-time control algorithms, and can achieve millisecond level instruction response to ensure precise synchronization of industrial equipment actions.

Multi interface compatibility and expansion: In addition to basic digital and analog interfaces, 2 expansion slots are reserved, which can be compatible with ABB dedicated signal acquisition modules and safety control modules, meeting the functional expansion needs in different scenarios; Simultaneously supporting multiple industrial communication protocols, easily integrating into existing automation systems.

Comprehensive fault diagnosis and protection: It has functions such as input and output signal disconnection detection, overvoltage/overcurrent protection, module temperature monitoring, etc. When abnormalities are detected, it can output real-time fault alarm signals (dry contacts/communication messages) and record fault codes for quick positioning and maintenance; And it supports saving power-off data to avoid the loss of key control parameters.

Wide environmental adaptability: Adopting a wide temperature design and anti vibration structure (compliant with IEC 60068-2-6 vibration standard), it can operate stably in industrial sites with high temperature, high dust, and slight vibration, reducing the impact of environmental factors on module performance.

Working principle

The ABB 3HAB8101-8/08Y industrial control module operates based on the closed-loop control process of "signal reception logic operation instruction output state feedback". The core steps are as follows:

Signal reception and preprocessing: The module receives signals from sensors (such as photoelectric sensors and pressure sensors) and upper computers (such as PLCs and industrial control computers) through digital/analog input interfaces; After the input signal is filtered to remove interference, it is converted into a digital signal that can be recognized by the microprocessor.

Logical operation and instruction generation: The microprocessor performs arithmetic processing on preprocessed signals based on preset control programs (such as device action logic and parameter threshold judgment); For example, when the analog input detects that the pressure value exceeds the set range, it triggers a logical judgment and generates a control command to adjust the valve opening.

Instruction output and execution control: Control instructions are converted into corresponding electrical signals through output interfaces and transmitted to underlying execution devices (such as relays, servo drivers, pneumatic valves) to drive the devices to perform corresponding actions; At the same time, the communication interface uploads command information and module working status in real-time to the upper computer, achieving data exchange.

Status monitoring and feedback: The module collects real-time output voltage, current, and its own temperature data, and compares them with preset thresholds; If there is an abnormality (such as output overcurrent, module overheating), immediately trigger the protection mechanism (cut off output or limit current), and output a fault signal through the alarm interface to complete closed-loop protection.

Precautions

Installation and wiring specifications:

Before installation, it is necessary to confirm that the module model matches the system requirements, and it is strictly prohibited to mix control modules of different models; When wiring, it is necessary to distinguish between the positive and negative terminals of the power supply and the input and output terminals to avoid module burnout caused by misconnection. It is recommended to use crimping terminals to connect wires and ensure reliable contact;

The module needs to be installed in a well ventilated control cabinet, with a distance of not less than 100mm from heating equipment (such as frequency converters) to prevent high temperatures from affecting module performance; If the temperature inside the control cabinet exceeds 40 ℃, a cooling fan or cooling device should be equipped.

Operational safety requirements:

Before powering on the module, it is necessary to check whether the power supply voltage is within the rated range (24V ± 10%) to avoid overvoltage damage; It is strictly prohibited to plug or unplug modules or disassemble wiring when in a live state. During maintenance, the power supply must be disconnected first, and the capacitor must be discharged (at least 3 minutes) before operation;

When programming and debugging, it is necessary to first backup the original control program to avoid program loss caused by misoperation; After modifying the parameters, a no-load test is required to confirm that there are no abnormalities before connecting the load device.

Maintenance and upkeep:

Conduct a visual inspection of the module every 3 months, clean the surface dust (wipe with a dry soft cloth, and prohibit the use of corrosive cleaning agents), check whether the wiring terminals are loose or oxidized, and promptly handle any abnormalities;

Perform one-time energy calibration annually, using specialized calibration equipment to test the accuracy of analog input and output, as well as the response time of digital signals, to ensure that module performance meets usage requirements; Modules that have been out of use for a long time (more than 6 months) must undergo a power test before being reactivated to confirm that there are no faults before being put back into use.

Application scenarios

Industrial robot control: As the core control unit of the robot control cabinet, it is responsible for receiving signals from robot body sensors (such as position sensors and torque sensors), generating joint motion commands, controlling the robot to complete precise grasping, assembly and other actions, and adapting to scenarios such as automotive welding and electronic component assembly.

Precision production line regulation: used in electronic chip and medical device production lines to monitor parameters such as conveyor belt speed, processing equipment temperature, material position, etc., adjust equipment operating status through logical operations, ensure consistency and high precision in the production process, and reduce product defect rates.

Heavy machinery automation: In heavy equipment such as machine tools and injection molding machines, the equipment operation panel and actuator are connected to achieve automatic control of equipment start stop and parameter adjustment (such as machine speed and injection pressure), and real-time monitoring of equipment load status to avoid overload damage.

Intelligent warehousing and logistics system: used for controlling stacker cranes and conveyor belts in three-dimensional warehouses, receiving scheduling instructions from the upper level warehousing management system, controlling equipment to complete cargo storage and transportation actions, and providing feedback on equipment operation status to improve the automation efficiency of warehousing and logistics.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-