Laser type: Using helium neon laser technology, it has continuous wave output, heterodyne characteristics, and linear polarization properties. The core vacuum wavelength is concentrated around 632.9915 nm (F1 vertical polarization, F2 horizontal polarization), and the wavelength stability reaches 0.005 ppm/hour, which can meet high-precision application requirements.

Safety compliance: Clearly classified as a Class II laser, compliant with NCDRH (National Committee on Laser Safety and Standards) regulations, and can provide basic protection through human eye blink reflex under normal use, reducing operational risks.

ZYGO ZMI 7702 8070-0102-01X Laser Head

Core positioning and technological foundation

Laser type: Using helium neon laser technology, it has continuous wave output, heterodyne characteristics, and linear polarization properties. The core vacuum wavelength is concentrated around 632.9915 nm (F1 vertical polarization, F2 horizontal polarization), and the wavelength stability reaches 0.005 ppm/hour, which can meet high-precision application requirements.

Safety compliance: Clearly classified as a Class II laser, compliant with NCDRH (National Committee on Laser Safety and Standards) regulations, and can provide basic protection through human eye blink reflex under normal use, reducing operational risks.

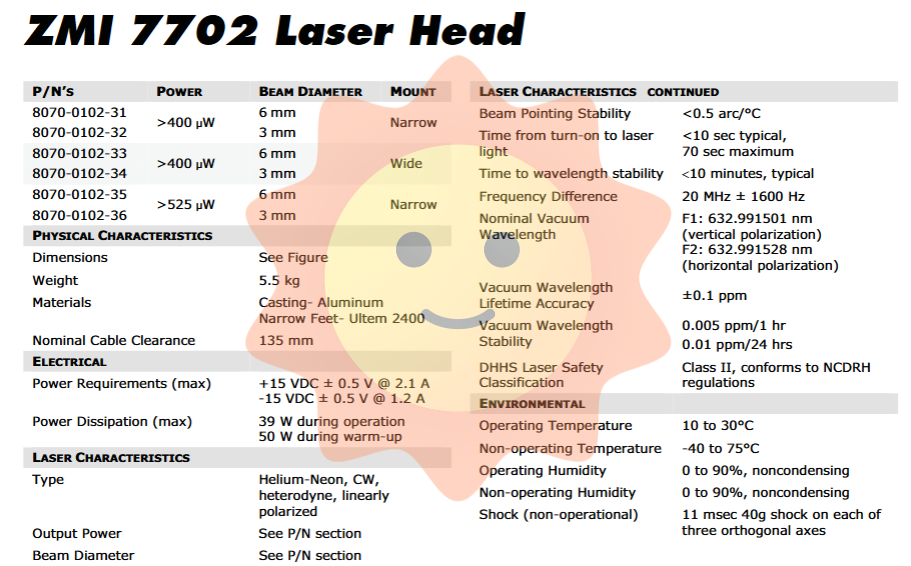

Core model parameters (differentiated by P/N)

Power: Models 31 and 33 have a power greater than 400 µ W; Model 36 has a power greater than 525 µ W; Models 32, 34, and 35 are not labeled.

Beam diameter: 6 mm for models 31, 33, and 35; 3 mm for models 32, 34, and 36.

Installation method (Mount): Models 31 and 36 are "Narrow"; Model 34 is "Wide"; Models 32, 33, and 35 are not labeled.

Key technical characteristics

1. Physical characteristics

Weight: 5.5 kg.

Material: The casting is made of aluminum, and the Narrow Feet are made of Ultem 2400 material.

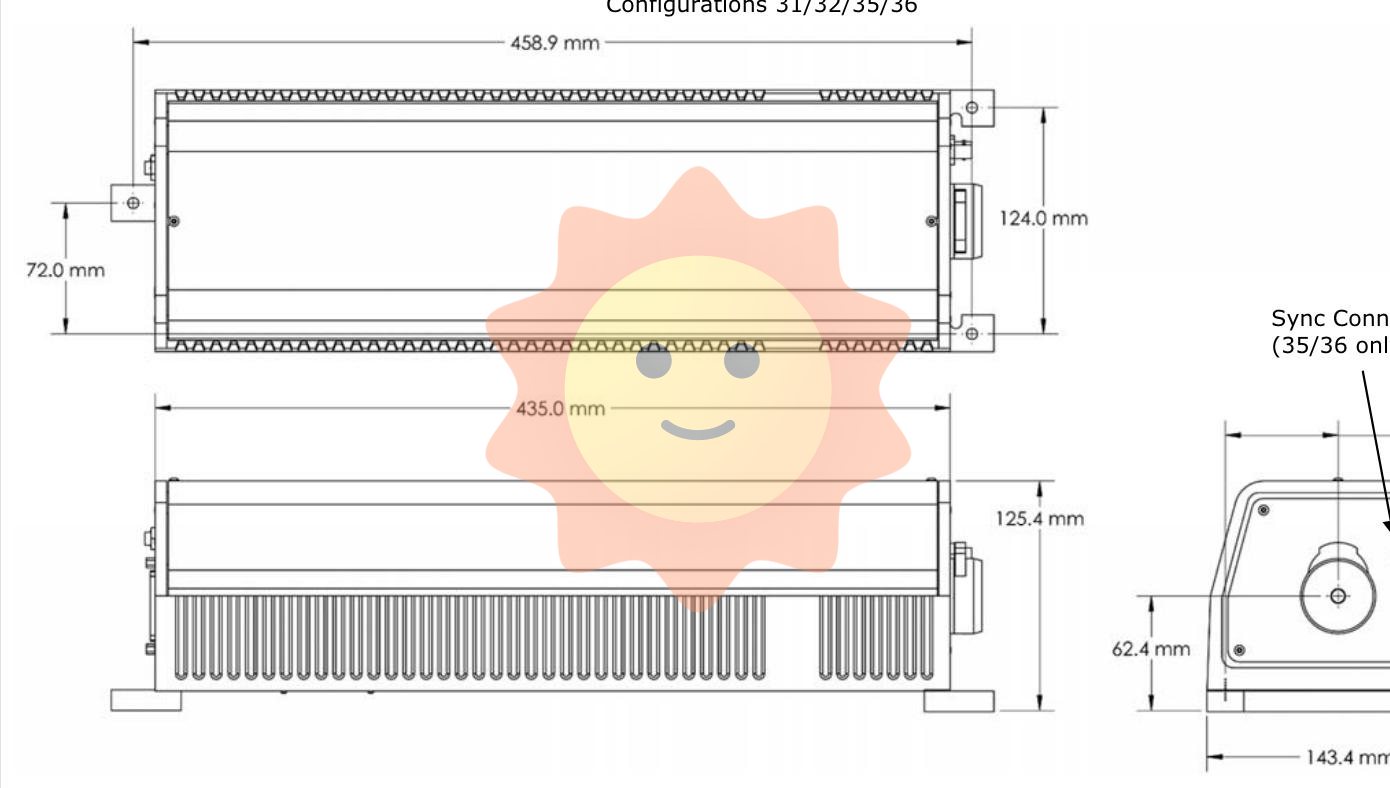

Cable gap: nominal 135 mm; size to refer to the "Figure" in the document (specific figure not attached).

2. Electrical requirements

Power requirements (maximum):+15 VDC ± 0.5 V (2.1 A), -15 VDC ± 0.5 V (1.2 A).

Power consumption (maximum): 39 W during operation and 50 W during preheating.

3. Laser characteristics

Laser type: Helium Neon laser, continuous wave (CW), heterodyne, linearly polarized.

Key performance: beam pointing stability<0.5 arc/° C; startup light output time is usually<10 seconds (up to 70 seconds); The wavelength stabilization time is usually less than 10 minutes.

Wavelength and frequency: The vacuum wavelength F1 (vertical polarization) is 632.991501 nm, and F2 (horizontal polarization) is 632.991528 nm; the frequency difference is 20 MHz ± 1600 Hz.

Safety level: Class II laser, compliant with NCDRH regulations.

4. Environmental adaptation range

Working temperature: 10-30 ° C; Non working temperature: -40-75 ° C.

Humidity (working and non working): 0-90% (no condensation).

Non working state impact resistance: All three orthogonal axis directions can withstand an impact of 11 milliseconds and 40 grams.

Safety precautions

1、 Clearly labeled laser safety requirements

Laser safety level: This laser head belongs to Class II laser and clearly complies with relevant regulations of NCDRH (National Committee on Laser Safety and Standards) in the United States.

Core safety tips for Class II lasers: Under normal use, the blink reflex of the human eye can provide protection, but it is still necessary to avoid prolonged, close range direct viewing of the laser beam to prevent potential eye damage.

2、 Safety precautions derived from device characteristics

1. Electrical safety

Strictly follow the power requirements: The equipment needs to be connected to a power supply of+15 VDC ± 0.5 V (2.1 A) and -15 VDC ± 0.5 V (1.2 A). It is forbidden to use power supplies that exceed the voltage or current range to avoid short circuits, overloads, equipment damage, or electrical fires.

Pay attention to peak power consumption: When the device is preheated, the power consumption reaches 50 W (39 W during operation). It is necessary to ensure that the power supply lines and sockets can carry the corresponding power to avoid overheating of the lines.

2. Environmental safety

Control the temperature and humidity of the working environment: The working temperature should be maintained at 10-30 ° C, the humidity should be 0-90%, and there should be no condensation; Although it can withstand temperatures between -40-75 ° C in non working conditions, long-term extreme environments may affect the lifespan of the equipment and indirectly increase the risk of failure. Therefore, it is necessary to avoid storing or using in such environments.

Non working state shock prevention: The equipment can withstand an impact of 11 milliseconds and 40 grams (in the direction of the three orthogonal axes) when not working, but any severe vibration or impact should be avoided during operation to prevent beam deviation, component damage, and potential safety hazards.

3. Physical operation security

Pay attention to the weight of the equipment: The weight of the equipment is 5.5 kg. When handling or installing, make sure to hold it firmly and place it steadily to avoid falling and injuring personnel or damaging the equipment.

Material and installation compatibility: The equipment castings are made of aluminum, and the narrow legs are made of Ultem 2400 material. Matching fixing components (such as accessories corresponding to the "Narrow" or "Wide" installation methods) should be used during installation to prevent equipment displacement caused by loose installation.

Possible models needed

ZMI-2002 8020-0211-1-J

8010-0105-01

PC200 CS1115-801-346

ZMI-4004

7702 8070-0102-01X

7702 8070-0102-35

ZMI-2002 8020-0211

4104C

HSSDC TO HSSDC2 CABLE 1115-800-056

HSSDC2 TO HSSDC2 CABLE 1115-800-055

1115-801-346

8010-0105-02 ZMI-501

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-