Type: Siemens SIMATIC ET200SP Server Module Operation Manual, version March 2015 (A5E0357537-AB), is a supplementary document to the ET200SP Distributed I/O System Manual, focusing on module specific functions. System level general functions should refer to the ET200SP System Manual (available through specified links).

Siemens ET200SP 6ES7193-6PA00-0AA0 server module

Overview and Basic Product Information

(1) Overview

Type: Siemens SIMATIC ET200SP Server Module Operation Manual, version March 2015 (A5E0357537-AB), is a supplementary document to the ET200SP Distributed I/O System Manual, focusing on module specific functions. System level general functions should refer to the ET200SP System Manual (available through specified links).

Document Structure: Includes 8 core chapters: Preface, Document Guide, Product Overview, Parameter/Address Space, Diagnostic Alarm, Technical Specifications, Parameter Data Recording, Dimensional Drawings, along with supporting safety warning system and compliance instructions.

(2) Product Fundamentals

Model and positioning: Model 6ES7193-6PA00-0AA0 is a server module for the ET200SP distributed I/O system. Its core function is to enclose the backplane bus and provide three backup fuses (5 × 20mm) for storage support. It needs to be used in conjunction with specific CPU/interface modules.

Compatibility: Only supports IM 155-6 PN BA interface module (product version ≥ 1, firmware version ≥ V1.1.1), can be configured through STEP 7 (TIA Portal) or GSD file.

Core functions and features

(1) Basic functions

Hardware Assistance: Integrated backup fuse storage location, convenient for quick access to fuses during on-site maintenance, without the need to carry additional spare parts boxes.

System support: Closed ET200SP backplane bus to ensure stable bus signals and avoid external interference; Support firmware updates, I&M identification data storage, and reconfiguration in RUN mode to enhance system flexibility and maintainability.

Status monitoring: It can monitor the power supply voltage (L+) and feedback voltage status of each slot I/O module in real time, and output the monitoring results through the address space, which is convenient for user programs to read and locate faults.

Device replacement optimization: When there is no topology configuration for IM 155-6 PN BA, the device name can be retained, and there is no need to reconfigure the name parameter after replacing the module, simplifying the replacement process.

(2) Key characteristics

Characteristic Details

Parameter configuration supports the "L+Power Loss Group Diagnosis" parameter (can be enabled/disabled, disabled by default). When enabled, 1 diagnostic message will be generated based on the potential group for L+power loss, regardless of the "L+Power Loss Diagnosis" parameter of the I/O module itself

The address space function outputs input data of different lengths based on the maximum number of I/O modules supported by the CPU/interface module (12/32/64 slots). It can choose to monitor only the power supply voltage or monitor both the power supply voltage and feedback voltage simultaneously

Diagnostic alarm is only a type 1 diagnostic alarm (error code 1BH), corresponding to "server module firmware version invalid (

Parameters and Address Space

(1) Parameter configuration

Configurable parameters: Only one parameter, "L+power loss group diagnosis", with a range of "enable/disable", disabled by default, supports reconfiguration in RUN mode (data recording needs to be transmitted through the "WRREC" command).

Parameter validation logic: After activation, the system generates a diagnosis based on the power supply status of the installed I/O modules in the potential group, requiring no empty slots in the potential group; When the light colored BaseUnit (BU.. D) has no I/O module, the potential group will be merged into the previous potential group. After inserting the I/O module, the potential group will be re identified and the diagnosis will be updated.

(2) Address space rules

1. Data length division

According to the maximum number of I/O modules supported by the CPU/interface module, the input data length is divided into three categories, as follows:

The maximum number of I/O modules supported is to monitor only the power supply voltage (in bytes) while monitoring both the power supply voltage and feedback voltage (in bytes). Only the diagnostic address (with no data) is supported

12 slots 2 4 0

32 slots 4 8 0

64 slots 8 16 0

2. Data interpretation rules

Power supply voltage monitoring: Each I/O module corresponds to one bit, bit=1 indicates "L+power supply is normal and the module exists", bit=0 indicates "L+power supply is missing or the module is not installed"; The server module's own slot outputs bit=0 regardless of whether it is installed or not.

Feedback voltage monitoring: Extra bytes of the same length as the supply voltage are occupied, with 1 bit corresponding to each I/O module. Bit=1 indicates "feedback voltage exists", and bit=0 indicates "feedback voltage is missing"; The I/O module without feedback voltage monitoring function has a bit status that is consistent with the "L+power loss" status (i.e. bit=0).

Data validity: When the server module is missing, all input data is invalid, and the module installation status needs to be checked first.

3. Feedback voltage evaluation

Voltage range definition: When L+supply voltage is greater than 6V, the feedback voltage status is included in the input data; When 6V

Evaluation scenario: Only when the L+power supply is safely disconnected (as indicated by the safety relay status), the feedback voltage bit=1 (6-12V or>12V) can be used as a fault diagnosis basis to locate system circuit abnormalities.

Technical specifications and installation

(1) Mechanical specifications

Parameter Value

Dimensions (width x height x depth) 7mm x 117mm x 36mm

Weight (approximately) 19g

The fuse supports three 5 × 20mm backup fuses

(2) Installation and Connection

Installation method: Suitable for ET200SP standard installation rails, no additional fasteners required, quick installation through rail buckles, compatible with other ET200SP modules in terms of layout.

Connection requirements: No independent I/O terminals, only connected to the system through the backplane bus, no additional wiring required, automatically connected to the system after installation.

Diagnosis and maintenance

(1) Diagnostic alarm processing

Diagnosis alarm type error code reason solution

Invalid firmware version 1BH server module firmware version

2. Firmware update of existing modules (requires specialized tools and processes)

(2) Parameter data recording

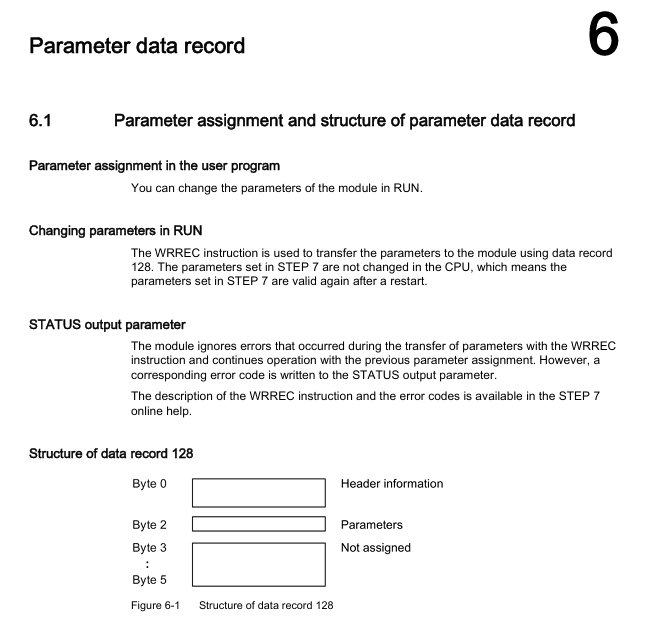

Parameter transmission: To modify parameters in RUN mode, the "WRREC" command is used to write the parameters into data record 128 (bytes 0-5, where byte 2 is the "L+power loss group diagnosis" enable bit, bit=1 enabled).

Error handling: When an error occurs during parameter transmission, the module ignores the error and maintains the original parameter configuration. At the same time, the error code is written into the "STATUS" output parameter. The meaning of the error code can be queried through STEP 7 online help.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-