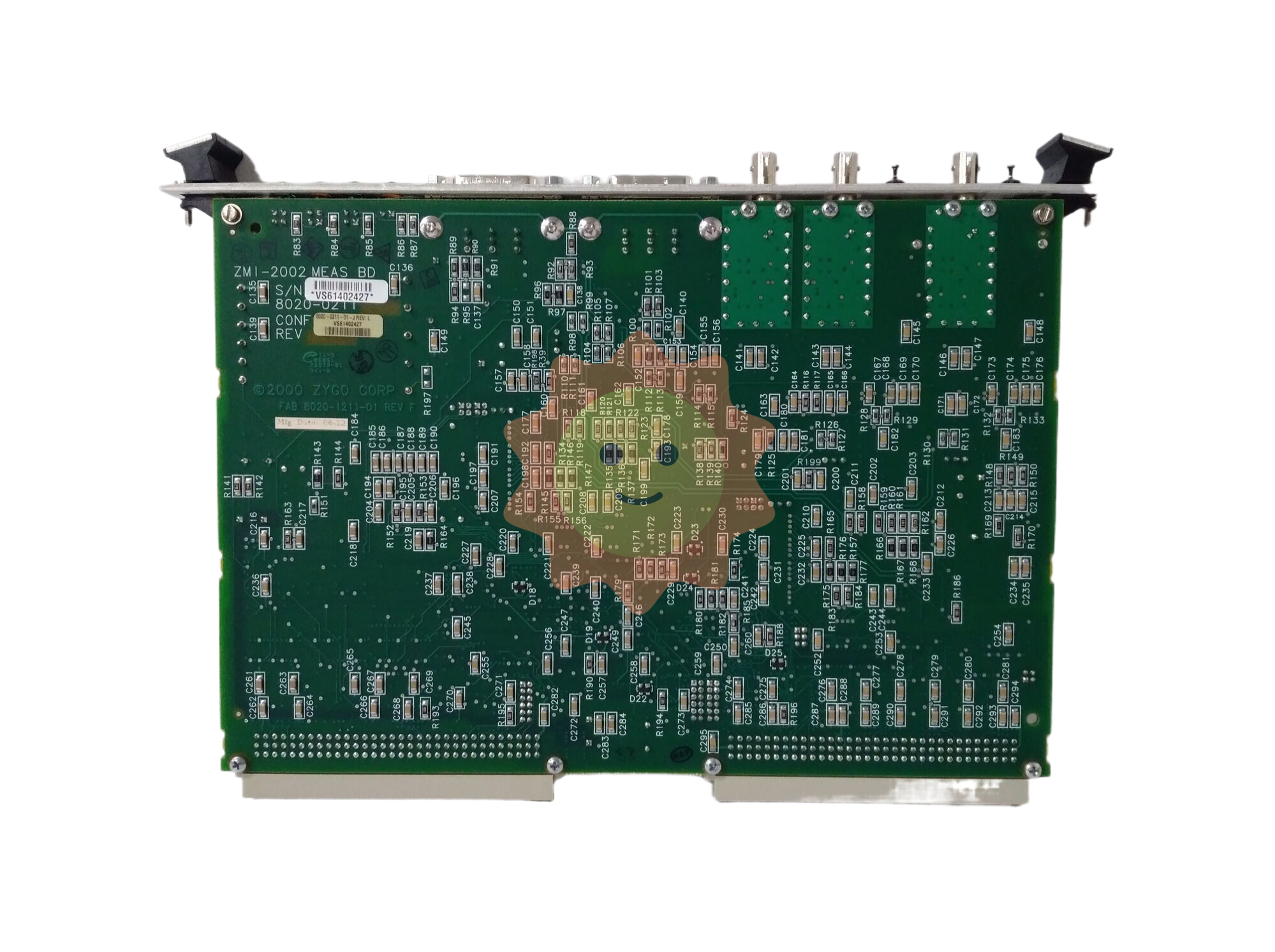

ZYGO 8010-0105-01 ZMI Power Supply is a dedicated power supply designed specifically for ZYGO ZMI series laser measurement control boards (such as ZMI-2002 mentioned earlier). Its core function is to provide stable and high-precision power support for laser measurement systems, ensuring the continuous and reliable operation of measurement boards and related components in complex industrial environments.

ZYGO 8010-0105-01 ZMI Power Supply

Core positioning and key parameters of the product

ZYGO 8010-0105-01 ZMI Power Supply is a dedicated power supply designed specifically for ZYGO ZMI series laser measurement control boards (such as ZMI-2002 mentioned earlier). Its core function is to provide stable and high-precision power support for laser measurement systems, ensuring the continuous and reliable operation of measurement boards and related components in complex industrial environments. The key parameters are as follows:

Output performance:

Output voltage: Multiple DC outputs, including+5V DC (± 0.02V),+12V DC (± 0.05V), and -12V DC (± 0.05V), to meet the power supply requirements of different modules on the board

Output current:+5V channel maximum output current 8A, ± 12V channel maximum output current 3A, total output power ≤ 80W

Voltage stability: ≤ 0.1% (under full load conditions, when the input voltage fluctuates within the rated range)

Ripple and noise: ≤ 50mVpp (+5V channel), ≤ 100mVpp (± 12V channel), low ripple ensures stable measurement signal

Input characteristics:

Input voltage range: 100-240V AC (wide input, suitable for different regional power grids)

Input frequency: 50-60Hz

Input power factor: ≥ 0.9 (at full load, 220V AC input)

Surge current: ≤ 50A (cold start, 220V AC input)

Physical and Environmental Specifications:

Size: 210 × 115 × 50mm (length × width × height), suitable for standard 19 inch industrial cabinet installation (1U height)

Weight: 1.8kg

Working temperature: 0 ° C-45 ° C (to match the working environment of ZMI measurement board)

Storage temperature: -20 ° C-70 ° C

Protection level: IP20 (prevents solid foreign objects from entering, suitable for installation environment inside the cabinet)

Heat dissipation method: natural heat dissipation combined with built-in low-noise fan (fan start stop temperature ≥ 40 ° C)

Security and authentication:

Compliant with IEC 61010-1 safety standard (safety requirements for electrical equipment for measurement, control, and laboratory use)

Equipped with overvoltage protection (OVP), overcurrent protection (OCP), short circuit protection (SCP), and over temperature protection (OTP) functions

Electromagnetic Compatibility (EMC): Complies with EN 55032 Class B (Radiated Disturbance Limits) and EN 61000-6-2 (Immunity Requirements)

Core functions and typical application scenarios

1. Core functions

As a key power supply unit of the ZMI series laser measurement system, its core functions revolve around "stable power supply" and "system protection":

High precision stabilized output: Adopting a switch power supply topology structure, coupled with a high-precision voltage feedback regulation circuit, to ensure that the output voltage accuracy is controlled within ± 0.1%, avoiding interference from voltage fluctuations on the nanometer level accuracy measurement of the laser measurement board.

Multi channel independent power supply: Distinguish between+5V,+12V, and -12V multiple outputs, which provide independent power supply for the digital signal processing module, analog measurement module, driver circuit, etc. of the board, reducing electromagnetic interference between different modules and improving overall system stability.

Comprehensive security protection:

Overvoltage protection: When the output voltage exceeds the rated value by 115% -130%, the power supply automatically cuts off the corresponding channel output to prevent damage to the board components due to overvoltage;

Overcurrent protection: When the output current of a single channel exceeds the rated value by 120% -150%, it triggers current limiting or cuts off the output to avoid power burnout caused by short circuit;

Over temperature protection: When the internal temperature of the power supply exceeds 85 ° C, the fan runs at full speed. When the temperature reaches 95 ° C, it automatically shuts down and can resume operation when the temperature drops below 70 ° C;

Short circuit protection: When a short circuit occurs at the output terminal, the power supply immediately enters protection mode. After the short circuit fault is eliminated, manual restart is required to restore power supply.

Status monitoring and alarm: The front panel is equipped with LED indicator lights (power operation indicator light, normal output indicator light for each channel, fault alarm light), which can intuitively display the power operation status; Some models support RS485 communication interface, which can upload operational data such as voltage, current, temperature, etc. to the control system for remote monitoring.

2. Typical application scenarios

This power supply is designed specifically for the ZYGO ZMI series laser measurement system and is mainly used in the following scenarios:

Laser interferometry measurement system: provides stable power supply for measurement boards such as ZMI-2002, laser generators, photodetectors, and other components, ensuring the smooth progress of high-precision measurement tasks such as semiconductor wafer thickness measurement and optical component surface contour detection.

Industrial laser processing equipment: compatible with ZMI measurement modules in laser cutting and welding equipment, providing reliable power support for real-time monitoring of laser focus position, workpiece displacement, etc., ensuring that processing accuracy meets requirements.

Precision Manufacturing Testing Platform: In high-end manufacturing fields such as aerospace components and precision molds, the testing platform supplies power to the ZMI series measurement system, ensuring the accuracy and stability of micrometer and nanometer level size detection.

Laboratory research and development system: used in laser measurement technology research and development scenarios, providing a controllable and stable power supply environment for ZMI boards and supporting equipment used in experiments, meeting the precise adjustment requirements of power supply parameters during the research and development process.

Operation and maintenance standards

1. Installation and commissioning

Installation requirements:

Installation location: It needs to be installed near the ZMI measurement board (reducing the length of power cables, lowering voltage loss and interference), avoiding proximity to high-power heating equipment (such as frequency converters and heaters), and ensuring that a heat dissipation space of ≥ 10cm is reserved around it;

Cabinet installation: It adopts the standard installation of a 19 inch cabinet and is fixed on the cabinet crossbeam with screws. During installation, it is necessary to ensure that the power supply and cabinet are well grounded (grounding resistance ≤ 4 Ω);

Cable connection: Use copper core cables that meet current specifications (16AWG cable is recommended for+5V channels, 18AWG cable is recommended for ± 12V channels), connect an air switch with leakage protection at the input end (rated current ≥ 5A), and connect the output end to the board interface to ensure that the positive and negative poles are not reversed (reverse connection may cause damage to the board and power supply).

Debugging process:

No load debugging: Disconnect the output connection between the power supply and the board, connect the input power supply, and observe whether the power indicator light on the front panel is lit up normally (usually green), and whether the output voltage indicator lights on each channel are lit up; Measure the voltage of each output terminal with a multimeter and confirm that the voltage value is within the rated range (e.g.+5V should be between 4.98V-5.02V);

Load debugging: Connect the power output terminal correctly to the ZMI measurement board, turn on the board power switch, observe whether the board starts normally, and whether the output indicator lights of each power channel remain normal; Run the board self-test program and monitor the fluctuation of the power output voltage to ensure that the fluctuation value is ≤ 0.02V;

Protection function test (optional, recommended to be performed during initial installation): Under the guidance of professional personnel, simulate fault scenarios such as overcurrent and short circuit (such as connecting an adjustable resistor in series with the+5V channel, gradually reducing the resistance value and increasing the current), confirm that the power protection function is triggered normally, and restore power supply after troubleshooting.

2. Daily maintenance and troubleshooting

Fault symptoms/possible causes/handling methods

No indicator light on the power supply, no output

1. Input power not connected (air switch not closed, poor cable contact); 2. The internal fuse of the power supply is burnt out; 3. Internal main circuit failure of the power supply (such as damaged rectifier bridge and switch tube)

1. Check the input power circuit, confirm that the air switch is closed, and re plug and unplug the cable to ensure good contact; 2. Disconnect the input power supply, open the power supply casing (requires professional operation), check the fuse (usually located near the input end), and if it burns out, replace it with a fuse of the same specification (such as 2A/250V); 3. If there is still no response after replacing the fuse, please contact ZYGO after-sales or professional maintenance personnel to check the main circuit

A certain channel has no output, and the corresponding channel indicator light is off

1. Poor contact or disconnection of the output cable of this channel; 2. Channel overvoltage/overcurrent protection triggered; 3. Internal voltage regulator circuit fault in the channel

1. Check the output cable of the channel, unplug or replace the cable again; 2. Disconnect the board card connection and measure the no-load voltage of the channel. If there is still no output, turn off the power for 30 seconds and restart to observe if it is restored (some protections require manual restart); 3. If there is still no output after restarting, it is necessary to check the internal circuit of the channel (such as feedback resistor, voltage regulator chip) and replace the power supply if necessary

Excessive fluctuation of output voltage (exceeding ± 0.05V)

1. The input voltage fluctuates too much (beyond the range of 100-240V); 2. Drift in the internal voltage feedback circuit of the power supply; 3. Unstable load (sudden change in current of a module on the board)

1. Measure the input power supply voltage. If the fluctuation is too large, a voltage regulator or UPS should be installed; 2. Contact ZYGO after-sales service and use a dedicated calibration tool to recalibrate the output voltage; 3. Check the load condition of the board, investigate whether there is a sudden change in current caused by module faults, repair the board fault, and then test the power supply

The power fan is not turning or the noise is too loud

1. Fan dust blockage; 2. Fan bearing wear; 3. Fan control circuit malfunction

1. Disconnect the power and use compressed air or a soft bristled brush to clean the fan dust; 2. If the noise is still too loud or does not turn after cleaning, it is necessary to replace the fan with a fan of the same specification (note that the fan voltage and speed parameters are consistent with the original fan); 3. If the fan still does not turn after replacing it, check the fan control circuit (such as temperature control chip, driving transistor)

Power shutdown due to overheating (triggered by overheating protection)

1. Insufficient heat dissipation space (obstructed by surrounding obstacles); 2. The ambient temperature exceeds 45 ° C; 3. Poor heat dissipation caused by fan failure; 4. Aging of internal components of the power supply (such as capacitor bulges) leads to increased power consumption

1. Remove obstacles around the power supply to ensure sufficient heat dissipation space; 2. Improve environmental heat dissipation (such as installing cabinet fans and air conditioning), and control the temperature below 45 ° C; 3. Check the operating status of the fan and replace it promptly if there is a malfunction; 4. Open the power casing and check the internal capacitors, resistors, and other components. If there are aging phenomena such as bulging or discoloration, replace the aging components

3. Preventive measures

Regular maintenance:

Monthly: Clean the dust on the front panel of the power supply and the ventilation openings of the cabinet, check if the input and output cables are securely connected, and observe if the LED indicator light is in normal condition;

Quarterly: Use a multimeter to measure the output voltage of each channel, record the voltage value, compare it with the initial debugging data, and if the deviation exceeds ± 0.03V, calibrate it in a timely manner; Check the grounding condition of the power supply to ensure that the grounding resistance is ≤ 4 Ω;

Every year: Professional personnel conduct a comprehensive cleaning of the interior of the power supply (with the input power disconnected), check for signs of aging in internal components, and test whether the protection function is normal.

Environmental control:

Temperature: Keep the working environment temperature between 0 ° C and 45 ° C, avoid direct sunlight or proximity to heat sources. It is recommended to install temperature sensors inside the cabinet to monitor temperature changes in real time;

Humidity: The relative humidity of the environment should be controlled between 20% and 80% (without condensation). Dehumidification equipment should be installed in humid environments to prevent internal components of the power supply from being affected by moisture and corrosion;

Electromagnetic environment: Keep away from strong electromagnetic interference sources (such as high-power transformers and high-frequency welding machines). If unavoidable, install electromagnetic shielding covers for the power supply and use shielded cables for input and output cables.

Spare parts and emergency management:

Spare parts reserve: It is recommended to equip 1-2 backup power supplies for key production equipment to ensure quick replacement in case of failure and reduce downtime; At the same time, reserve vulnerable parts such as fuses and fans, label specifications and replacement cycles;

Emergency response: Develop an emergency plan for power failures, clarify the troubleshooting process, contact information for maintenance personnel, and steps for replacing backup power sources. Regularly organize operator training to ensure quick response in the event of a failure.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-