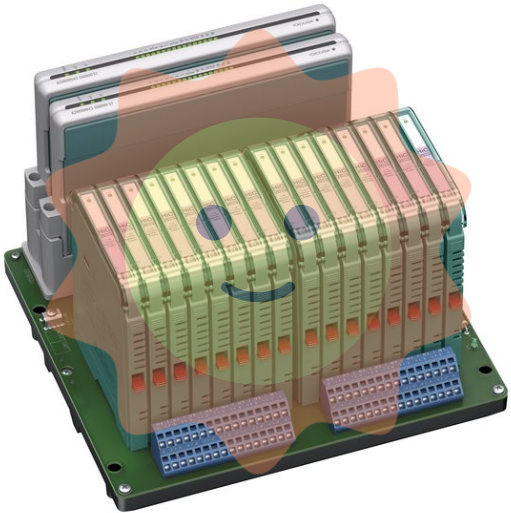

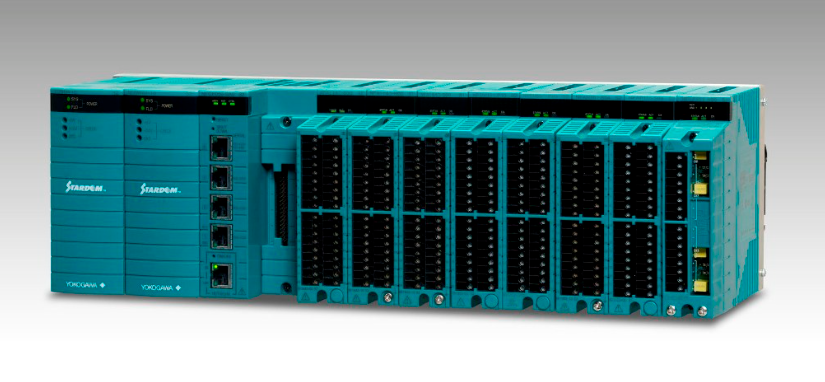

HIMA F3236: 16-Channel Digital Input Module for Advanced Industrial Control Solutions

The HIMA F3236 16-Channel Digital Input Module is an advanced industrial control component designed for high-reliability digital signal processing. It offers precise input handling and compatibility across various industrial applications, ensuring seamless integration into complex systems. Number of Channels:16 Channel Type:Digital Input Operating Voltage:24V DC Current Consumption per Channel:鈮?5mA Response Time:鈮?5ms Communication Interface:Modbus RTU Operating Temperature:-25掳C to +70掳C Storage Temperature:-40掳C to +85掳C Enclosure Type:IP65 Rated Certifications:CE, UL, CSA The HIMA F3236 Digital Input Module is engineered to deliver high-performance in demanding industrial applications.

With its 16-channel design, it ensures comprehensive monitoring and control capabilities, making it indispensable for modern manufacturing processes. Featuring an IP65-rated enclosure, this module is built to withstand harsh environments, ensuring consistent operation under varying conditions. Its robust construction supports continuous performance without compromising safety standards. Equipped with a fast response time of 鈮? milliseconds, the HIMA F3236 guarantees immediate action upon detection of input signals, enhancing system responsiveness and operational efficiency.

Compatible with Modbus RTU, the communication interface facilitates seamless integration with a wide range of industrial automation systems. This compatibility simplifies setup and maintenance, streamlining the implementation process. Certified to stringent international standards including CE, UL, and CSA, the HIMA F3236 ensures compliance and reliability across diverse global markets. Trust in the superior quality and safety features provided by HIMA technology. Tag F3236, F3236 Digital Input Module, F3236 PDF, F3236 Picture, HIMA F3236, HIMA F3236 PDF

Instructions and warnings related to the operation of the product:

The following specifications must be strictly observed:

l The technical specifications and typical applications of the product system must be strictly observed.

l PERSONNEL TRAINING: Only trained personnel may install, operate, maintain or repair the product system. These personnel must be instructed on the

Hazardous area conditions must be instructed and explained to these personnel.

l Unauthorised modifications: No modifications or structural changes may be made to the product system.

l Maintenance Responsibility: It must be ensured that the product system is only used under appropriate conditions and in a condition that is fully fit for purpose.

l Working environment: The user must fulfil the specified environmental conditions:

Safety regulations

The following safety regulations must be fully observed when (maintenance) work is carried out on the product system:

1 Disconnect completely.

2 Secure to prevent reconnection.

3 Confirm that the installation has been completed.

4 Perform grounding and short-circuiting.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-