HIMA F8651E Industrial Grade CPU Module, Precision Control for Critical Environments

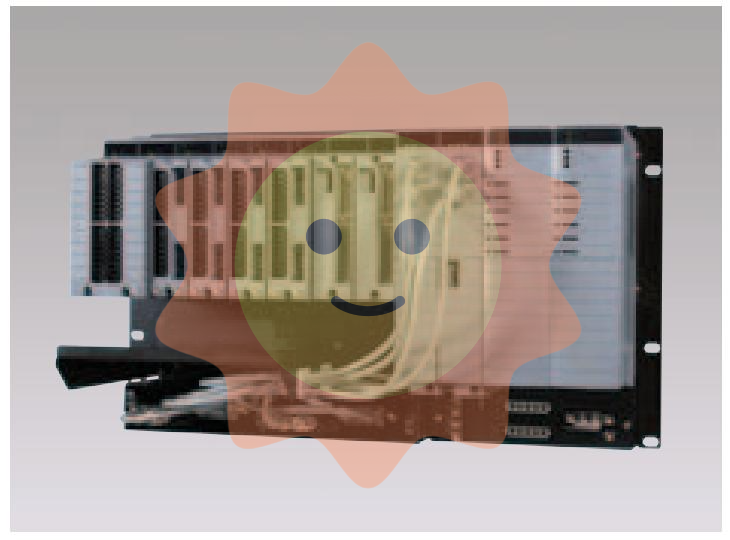

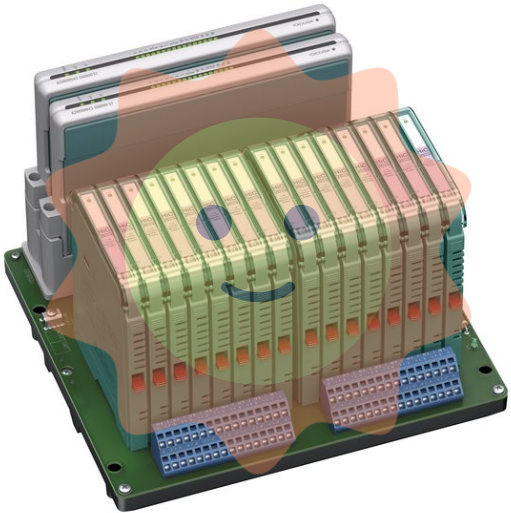

The HIMA F8651E CPU Module is a robust, high-performance industrial control solution designed for demanding automation environments. It ensures reliable operation, enhanced efficiency, and superior safety in manufacturing processes. Model Number:F8651E Type:CPU Module Designation:Industrial Control Operating Voltage:12V DC Operating Current:鈮?00mA Communication Interface:RS-485, CAN Storage Temperature:-40掳C to +85掳C Operating Temperature:-20掳C to +70掳C Dimensions:80mm x 110mm x 70mm Weight:0.2kg The HIMA F8651E CPU Module is a high-performance, compact design specifically engineered for integration into complex safety-critical systems.

It boasts an enhanced processing speed, enabling faster execution of tasks and improved system responsiveness. Equipped with robust communication capabilities through Profinet, this module facilitates seamless integration with other devices in the network, ensuring smooth data exchange and control across the entire manufacturing line. With a memory capacity of at least 128 MB RAM and 2 MB Flash, the HIMA F8651E CPU Module provides ample space for storing application programs, user data, and configuration settings, ensuring flexibility and adaptability to diverse industrial requirements.

Featuring 8 inputs and 6 outputs, it supports a wide range of signal types, making it suitable for various control applications, from simple on-off switches to complex process control scenarios. Designed with an operating temperature range of -25掳C to +60掳C, this module is built to withstand harsh industrial conditions, guaranteeing reliable operation in extreme environments. The IP20 protection class ensures basic protection against accidental contact with moving parts and dust ingress, safeguarding the module internal components and enhancing its durability. Tag F8651E, HIMA F8651E, HIMA F8651E datasheet, HIMA F8651E pdf, new F8651E, sell F8651E

Instructions and warnings related to the operation of the product:

The following specifications must be strictly observed:

l The technical specifications and typical applications of the product system must be strictly observed.

l PERSONNEL TRAINING: Only trained personnel may install, operate, maintain or repair the product system. These personnel must be instructed on the

These personnel must be instructed and briefed on the conditions in the hazardous area.

l Unauthorised modifications: No modifications or structural changes may be made to the product system.

l Maintenance Responsibility: It must be ensured that the product system is only used under appropriate conditions and in a condition that is fully fit for purpose.

l Working environment: The user must fulfil the specified environmental conditions:

Safety regulations

The following safety regulations must be fully observed when (maintenance) work is carried out on the product system:

1 Disconnect completely.

2 Secure to prevent reconnection.

3 Confirm that the installation has been completed.

4 Perform grounding and short-circuiting.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-