The technical parameters of RH928AW are fully adapted to the strict operational requirements of industrial grade, and the core indicators are as follows:

Power supply specifications: 24V DC power supply is adopted, which complies with the general power supply standards for industrial automation equipment, ensuring the adaptability and stability of the power supply.

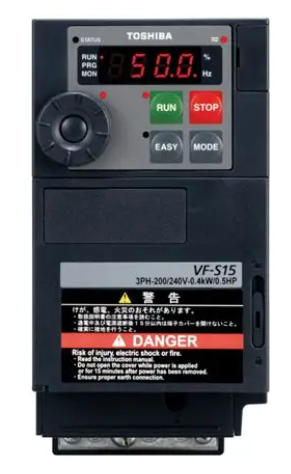

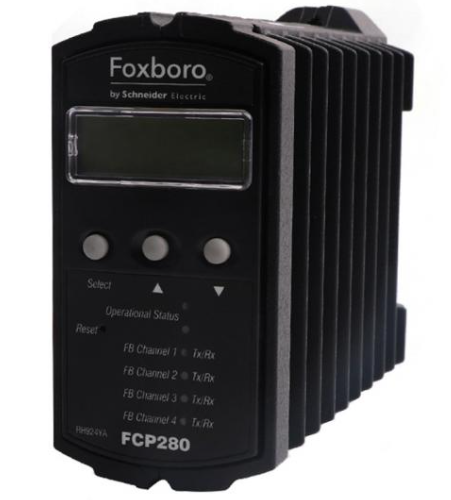

FOXBORO RH928AW control module

Core technical parameters

The technical parameters of RH928AW are fully adapted to the strict operational requirements of industrial grade, and the core indicators are as follows:

-Power supply specifications: 24V DC power supply is adopted, which complies with the general power supply standards for industrial automation equipment, ensuring the adaptability and stability of the power supply.

-Environmental adaptability: The working temperature range covers -40 ℃ to+70 ℃, and can withstand extreme high and low temperature environments; The humidity adaptation range is 0% to 95% non condensing, which can cope with high humidity conditions; Vibration protection reaches 5g RMS (20Hz to 2000Hz), and impact protection reaches 15g (11ms half sine wave), which can resist mechanical vibration and impact interference in industrial sites.

-Protection level: up to IP67, with complete dust and short-term water immersion protection capabilities, can be directly installed in dusty and humid on-site environments without the need for additional protective enclosures.

-Processor performance: Equipped with a 32-bit RISC high-performance processor, it has fast computing capability and can efficiently execute complex control logic, ensuring real-time response of control instructions.

Core functions and design advantages

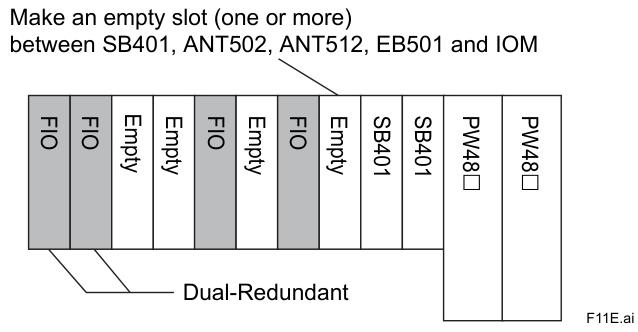

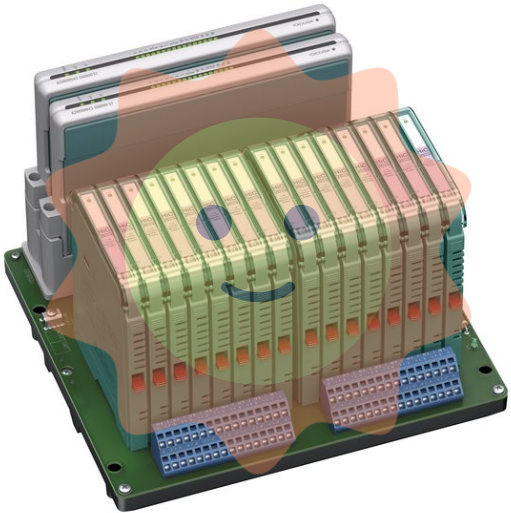

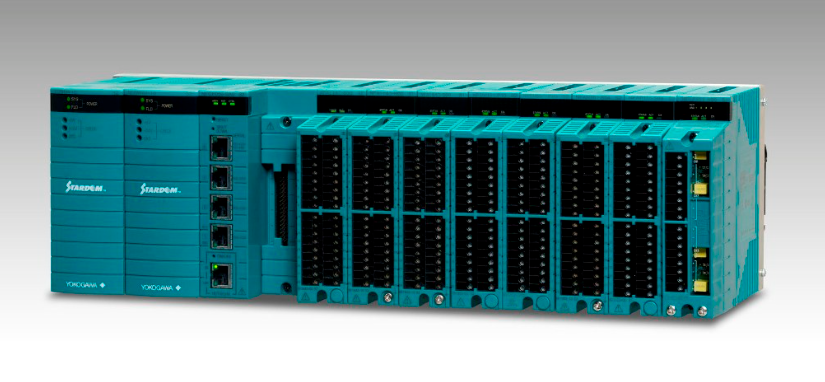

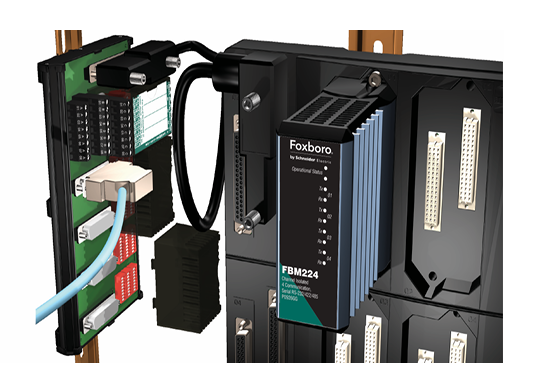

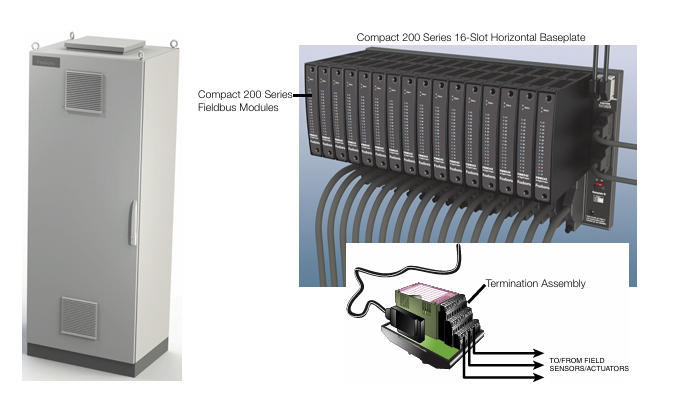

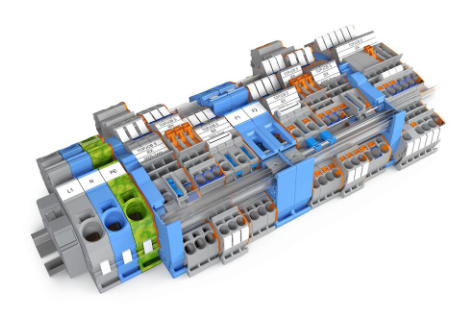

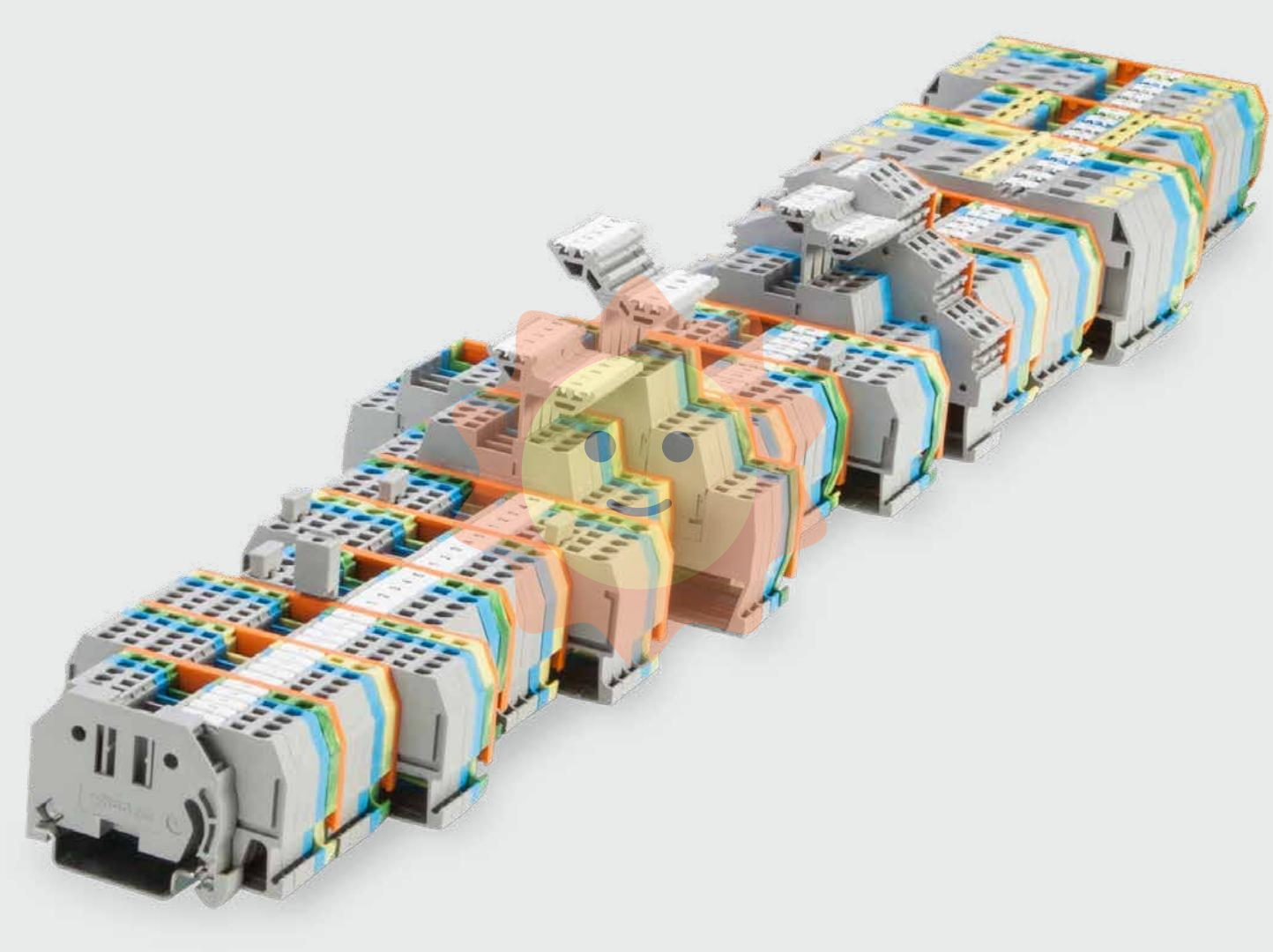

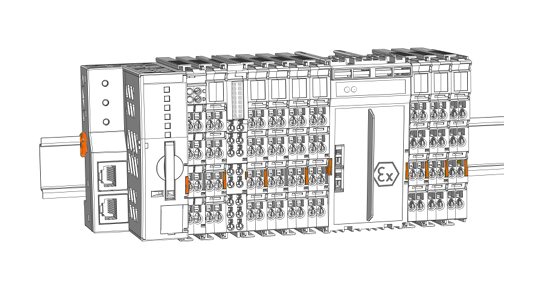

1. Modular design, flexible expansion

RH928AW adopts a standardized modular architecture and supports multiple input/output (I/O) module extensions, including digital input/output modules, analog input/output modules, and dedicated communication modules. Users can flexibly increase or decrease the number and types of modules according to specific application scenarios, achieving customized configuration of control functions. This not only reduces initial procurement costs, but also provides convenience for subsequent system upgrades and expansions, adapting to different scale requirements from small control units to large distributed control systems. Meanwhile, modular design facilitates troubleshooting and component replacement, significantly reducing maintenance downtime.

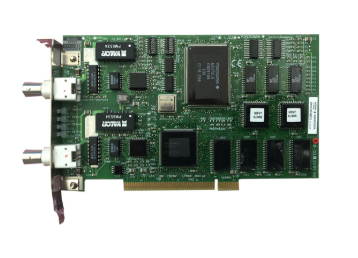

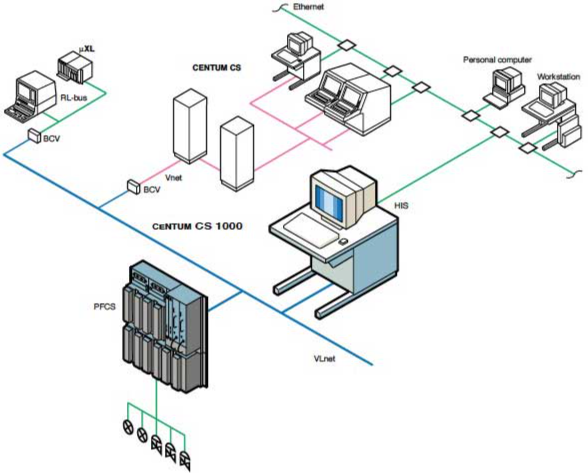

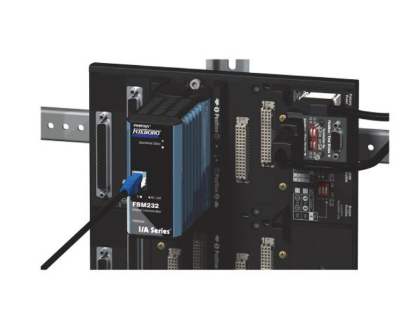

2. Multi protocol compatibility, strong communication capability

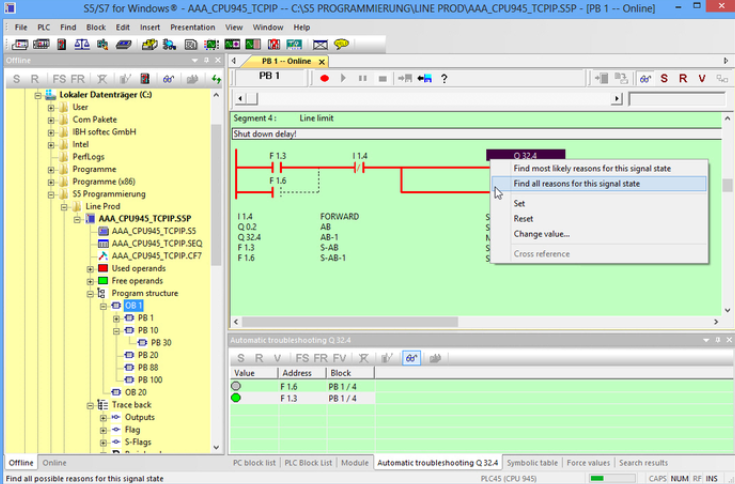

This module is equipped with a variety of communication interfaces, including RS-232, RS-485 serial interfaces and Ethernet interfaces, supporting multiple mainstream industrial communication protocols such as Modbus, Profibus, DeviceNet, etc. Among them, the Modbus Master TCP driver of Foxboro Evo system can be connected through Ethernet interface to achieve high-speed data exchange with Modbus TCP devices, and cross device and cross system information synchronization can be achieved through TCP/IP protocol. In addition, it can also be connected to serial Modbus slave devices through a protocol gateway, further expanding the scope of system integration and easily integrating into existing industrial automation networks, achieving seamless collaboration with upper computers, sensors, actuators, and other devices.

3. Convenient programming, adaptable to diverse control requirements

RH928AW supports multiple industry standard programming languages, including Ladder Logic, Function Block Diagram, Structured Text, and more. Engineering and technical personnel can choose the appropriate programming language for program development based on their own programming habits and control logic complexity, reducing programming barriers and learning costs. At the same time, relying on the software support of Foxboro Evo system, program download, debugging and fault diagnosis can be achieved through the system manager, which improves programming and maintenance efficiency.

4. High reliability, ensuring continuous operation

The product adopts industrial grade high stability components, combined with rigorous production processes and environmental adaptability design, and has strong anti-interference ability and operational stability. Its dust-proof, waterproof, and anti vibration and impact characteristics enable it to operate stably for a long time in harsh working conditions such as high temperature and high pressure environments in the petrochemical industry, dust environments in the power industry, and mechanical vibration environments in discrete manufacturing, effectively reducing the probability of equipment failure and ensuring the continuity of industrial production. In addition, the product also provides a 12-month warranty period, further safeguarding the user's usage rights.

Applicable industries and typical application scenarios

With its excellent environmental adaptability and functional scalability, RH928AW is widely used in multiple industrial fields, with typical scenarios including:

-Petrochemical industry: Used for collecting and controlling parameters such as temperature, pressure, and flow rate in crude oil extraction and refining processes, achieving precise control of reaction vessels and pipeline transportation systems, and adapting to high temperature, high pressure, and high humidity on-site environments.

-Electric power industry: applied to the unit control system of thermal power generation and hydropower generation, responsible for collecting the operating parameters of the generator set (such as speed, load, temperature), and executing instructions such as start stop control and load adjustment, adapting to the environment of machine rooms with high dust and strong vibration.

-Discrete manufacturing industry: used for automation control of production lines such as automotive parts production and mechanical processing, achieving collaborative control of conveyor belts, processing equipment, robots and other equipment, and ensuring synchronous operation of various links in the production line through multi protocol communication.

-Other industries: It can also be applied to automation systems in water treatment, metallurgy, building materials and other fields, undertaking core functions such as data collection, logic control and equipment linkage.

Installation and commissioning precautions

1. Preparation before installation

Before installation, sufficient preparation work should be done: first, check whether the equipment model, specifications, purchase order, and technical requirements are consistent, open the box and inspect the appearance of the equipment for damage, confirm that the modules, interfaces, accessories, etc. are complete and correct, and contact the supplier in a timely manner if there are any problems; Secondly, according to the equipment installation instructions, prepare installation tools and auxiliary materials such as screwdrivers, wrenches, drills, screws, washers, etc; Finally, check the installation site environment to ensure that it is dry, ventilated, temperature and humidity meet the requirements for equipment operation, reserve sufficient space for operation and maintenance, and ensure stable power supply with voltage fluctuations that meet equipment requirements.

2. Installation specifications

During the installation process, the following specifications must be strictly followed: select the appropriate installation position, determine the installation direction based on the "Top" label of the equipment, mark the mounting points and drill guide holes, use appropriate screws to firmly fix the equipment, ensure that the installation is flat and horizontal, and avoid measurement or control errors caused by tilting; If the knockout hole of the cutting equipment needs to be used for wiring, it is necessary to ensure that the aperture matches the connector, and install conduits and waterproof connectors to ensure good sealing, especially in humid or dusty environments where protection needs to be strengthened; The connection between modules and expansion modules should be operated according to the instructions to ensure a secure connection and avoid poor contact.

3. Wiring and Connection Points

Wiring and connection are key links to ensure the normal operation of equipment: Wiring should follow the principles of safety, standardization, and cleanliness, plan the route of the line reasonably, avoid cross winding of the line, use cable trays or conduits to protect the line and prevent damage; The power and signal lines need to be wired separately and isolated to prevent signal interference; The line connection must be strictly executed according to the equipment wiring diagram to ensure accurate and secure wiring, especially paying attention to the positive and negative connections between the communication interface and the power interface to avoid equipment damage caused by reverse connection; After the wiring is completed, organize and store the excess lines to avoid wire compression or loosening.

4. Debugging and acceptance process

Before debugging, a system check is required to confirm that the power connection is normal and that the circuit is not damaged or short circuited; Check whether the program is loaded correctly and whether the parameter settings meet the design requirements through the Foxboro Evo system manager. The debugging process is divided into individual debugging and linkage debugging: individual debugging requires testing the various functions of the module, such as data acquisition accuracy, control instruction execution, communication stability, etc; Linkage debugging requires testing the collaborative working ability of modules with other devices and upper level systems to ensure the normal operation of the entire control system. After passing the debugging, acceptance will be carried out, including the stability of equipment operation data, functional integrity, and ease of operation. After passing the acceptance, an acceptance report will be submitted, including basic equipment information, installation status, test results, and training for operators on usage and maintenance.

5. Safety operation guidelines

During the installation and debugging process, safety regulations must be strictly followed: the system's main power supply must be disconnected before operation to avoid electric shock or equipment damage caused by live operation, and power supply can only be restored after installation and debugging are completed; Operators need to wear safety goggles, gloves and other protective equipment to avoid accidental injuries; All electrical installations must comply with local building and safety regulations and be carried out by qualified professionals; If any abnormalities occur during the operation of the equipment (such as overheating, abnormal noise, or fault alarm), the machine must be stopped immediately for inspection and troubleshooting before it can be restarted.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com