WOODWARD 9905/9907 CONTROLLER

WOODWARD 9905/9907 CONTROLLER

OVERVIEW

The 9905/9907 series of the Woodward 2301A controls load sharing and speed of generators driven by diesel or gasoline engines, or steam or gas turbines. These power sources are referred to as “prime movers” throughout this manual.The control is housed in a sheet-metal chassis and consists of a single printed circuit board. All potentiometers are accessible from the front of the chassis.The 2301A provides control in either isochronous or droop mode.

The isochronous mode is used for constant prime mover speed with:

Single-prime-mover operation;

Two or more prime movers controlled by Woodward load sharing control systems on an isolated bus;

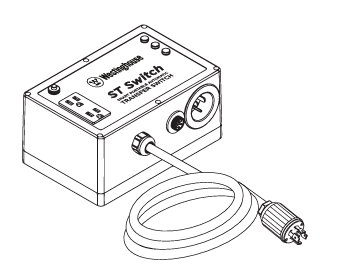

Base loading against an infinite bus with the load controlled by an Automatic Power Transfer and Load (APTL) Control, an Import/Export Control, a Generator Loading Control, a Process Control, or another load-controlling accessory.

The droop mode is used for speed control as a function of load with:

Single-prime-mover operation on an infinite bus or

Parallel operation of two or more prime movers.

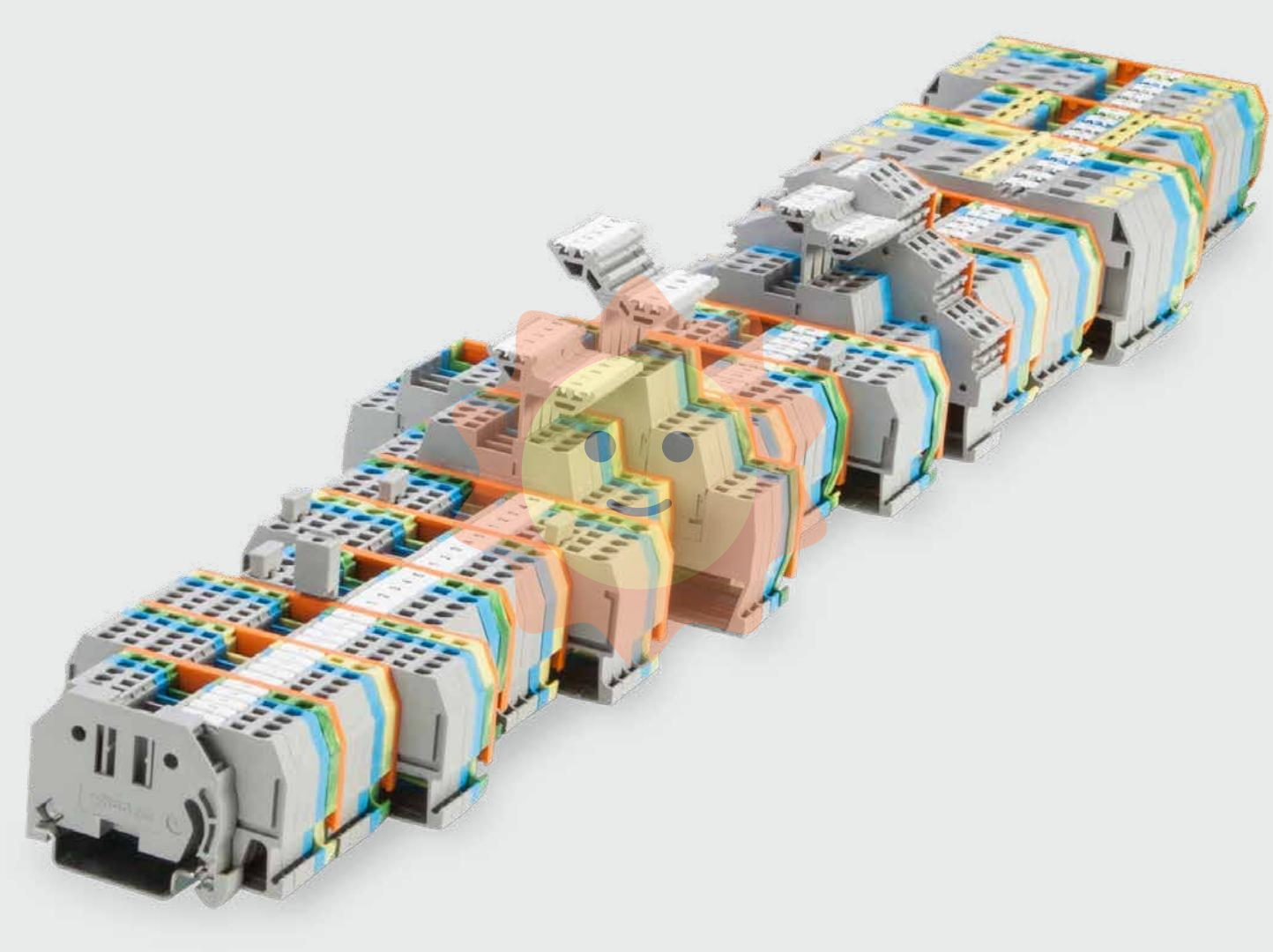

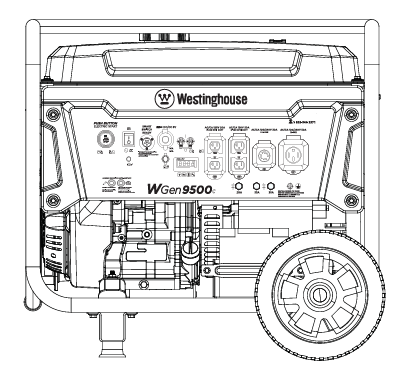

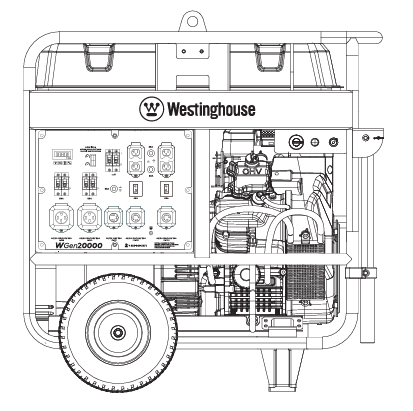

The following is an example of the typical hardware needed for the 2301A system controlling a single prime-mover and generator:

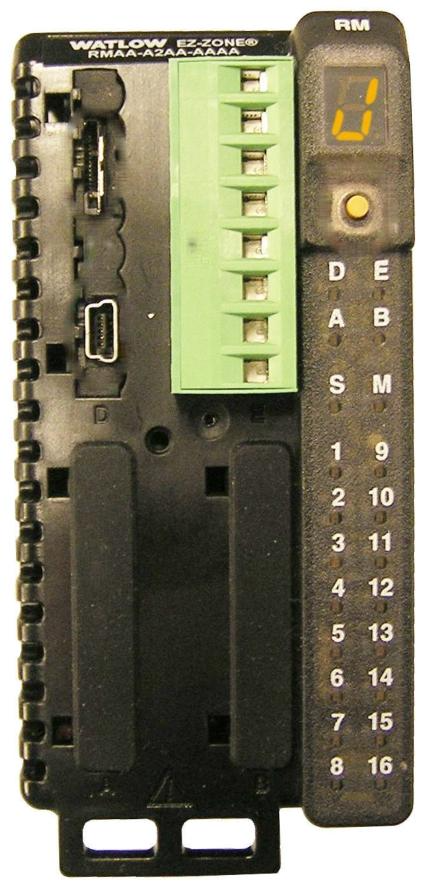

A 2301A electronic control

An external 20 to 40 Vdc power source for low-voltage models; 90 to 150 Vdc or 88 to 132 Vac for high-voltage models

A proportional actuator to position the fuel-metering device, and

Current and potential transformers for measuring the load carried by the generator.

This product is intended for installation in a “closed electrical operating area” or in a closed industrial control cabinet. Consider these requirements when selecting the mounting location:

Adequate ventilation for cooling

Space for servicing and repair

Protection from direct exposure to water or to a condensation-prone environment

Protection from high-voltage or high-current devices, or devices which produce electromagnetic interference

Avoidance of vibration

Selection of a location that will provide an operating temperature range of –40 to +70 °C (–40 to +158 °F)

The control must NOT be mounted on the engine.

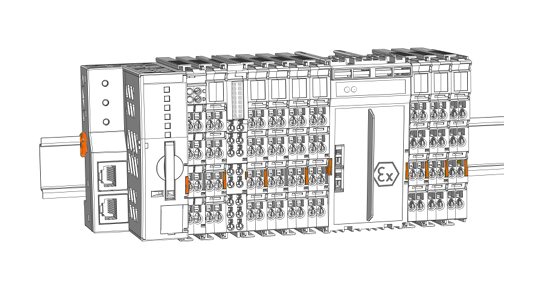

Product Features

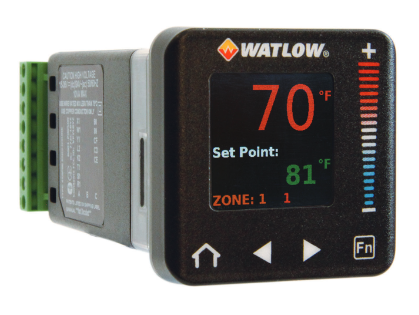

High-precision control: WOODWARD 9905/9907 CONTROLLER adopts high-precision sensors and actuators, which can realise precise control of the controlled object and improve the stability and reliability of the system.

Programmability: These controllers support a variety of programming languages, users can be programmed according to the actual needs, to achieve custom control logic and algorithms.

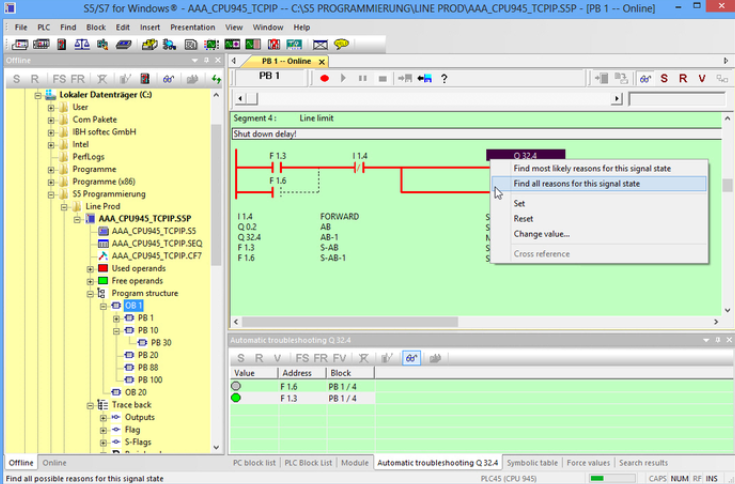

Multifunctionality: In addition to basic control functions, WOODWARD 9905/9907 CONTROLLER is also equipped with a variety of functions such as data logging, troubleshooting, remote communication, etc., which is convenient for users to carry out equipment management and maintenance.

Easy to install and maintain: The controller adopts modular design, which makes it easy to install and replace parts. At the same time, its friendly user interface and rich documentation support also reduces the user's maintenance difficulty.

Specific Models and Features

WOODWARD 9905 Series:

This series of controllers may include several specific models, such as the 9905-020, 9905-021, etc., each of which may have different control functions and application ranges.

Some models may support dual actuator systems with reverse acting capability and actuator currents up to 0-200 mA.

WOODWARD 9907 Series:

Also contains several specific models, such as 9907-014, 9907-018, 9907-1200, etc., each designed for different control needs.

Some models may have features such as an overspeed protection system, load sharing and speed control for application scenarios that require higher safety and stability.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com