531X307LTBAKG1 | General Electric LAN Terminal Board 531X Series

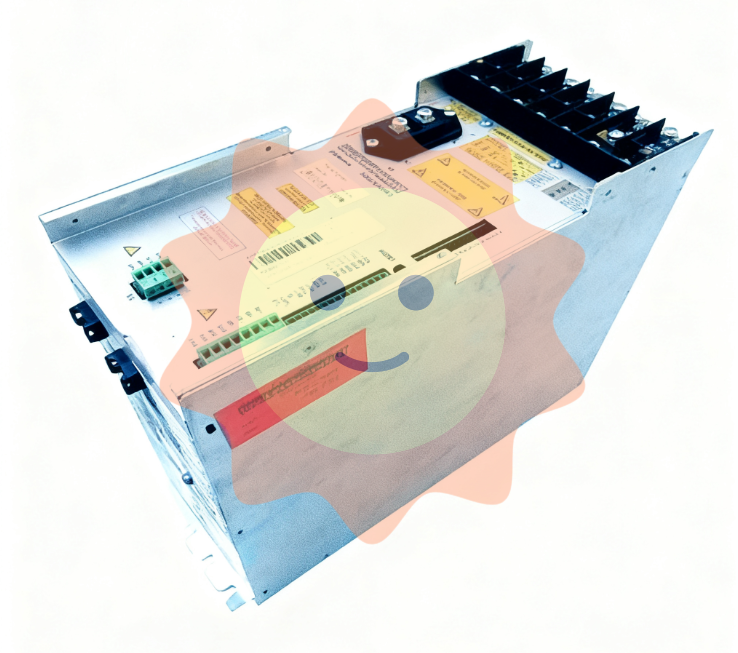

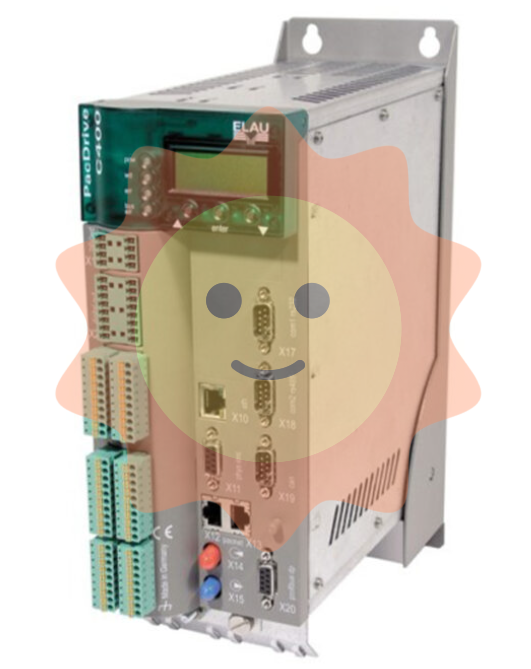

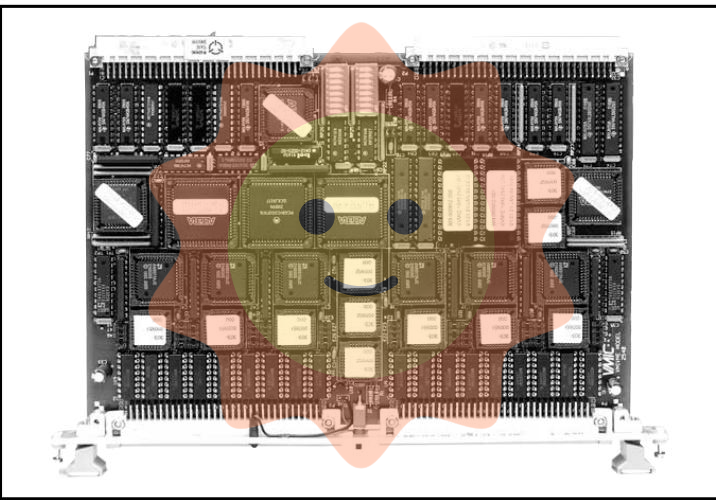

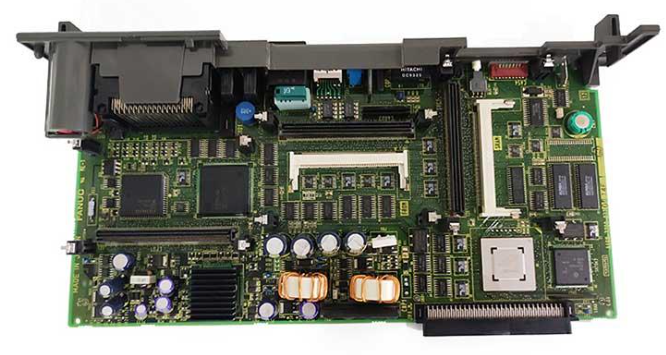

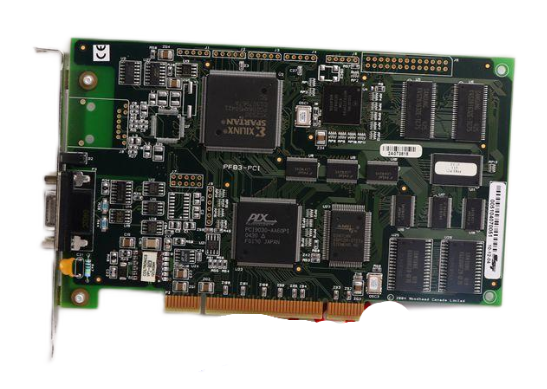

Product Description P/N: DS3800NSCD Description / Specifications Description The DS3800NSCD by General Electric is a Printed Circuit Board designed for use in industrial control systems. It facilitates crucial functions and connectivity within the system, ensuring reliable performance and stable operation of connected components. This board is essential for maintaining efficient and consistent control in automation applications.

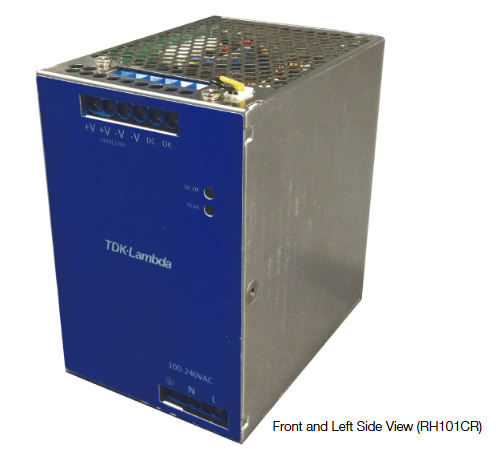

Technical Specifications Part Number DS3800NSCD Manufacturer General Electric Series Mark IV Product Type Speed Current Regulator Board Power Requirements +5 V dc Power Supply Voltage 28 V dc Operating Temperature -35 to +55掳C Size 15.7 cm high x 17.5 cm Weight 0.5 kg Availability In Stock Country of Origin United States Information About DS3800NSCD The General Electric DS3800NSCD is a Printed Circuit Board (PCB) designed for the Mark IV control series, specifically functioning as a Speed Current Regulator Board. This essential component plays a crucial role in regulating the speed and current within industrial control systems, ensuring accurate and stable performance across various applications.

The DS3800NSCD operates with a power requirement of +5 V DC, while the board itself is powered by a supply voltage of 28 V DC. This configuration ensures that the board can effectively manage the electrical needs of the control system, providing reliable performance and supporting the overall stability of the system. Engineered to withstand demanding industrial environments, the DS3800NSCD features an operating temperature range of -35掳C to +55掳C. This wide temperature range ensures that the board can function reliably in various environmental conditions, making it suitable for use in both extreme cold and high-temperature settings. The robust design of the board contributes to its durability and reliability in challenging industrial applications.

The PCB measures 15.7 cm in height and 17.5 cm in width, with a weight of 0.5 kg. These dimensions make it a compact yet efficient component within the control system, providing essential functionality without occupying excessive space. The board's size and weight are optimized for integration into existing setups, ensuring that it can be installed and configured with ease. In summary, the General Electric DS3800NSCD Printed Circuit Board is a key component in the Mark IV control series, serving as a Speed Current Regulator Board. Its power requirements, wide operating temperature range, and compact size make it a reliable and efficient choice for managing speed and current in industrial control systems.

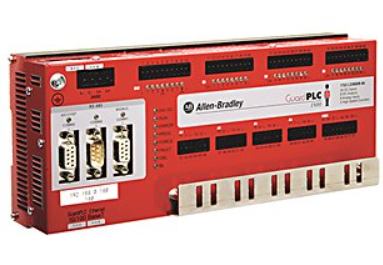

Manufacturer information General Electric (GE) is a multinational conglomerate founded in 1892, based in the United States. It operates in various industries, including aviation, healthcare, renewable energy, and power. GE is known for its innovations in technology, manufacturing, and infrastructure solutions. IQElectro is not an authorized distributor. QElectro LLC (IQElectro) is NOT an Authorized Distributor or in any way affiliated with Rockwell Automation, Siemens, or any other Manufacturers. IQElectro is NOT an Authorized Dealer of this product. The product may be of older version, date codes, or design than that available from authorized dealers. As IQElectro is not an authorized dealer of this product, the Original Manufacturer's Warranty and Support DO NOT apply.IQElectro sells SURPLUS onlyand DOES NOT SELL SOFTWARE or FIRMWARE licenses For more detailed information, please refer to the full version of our disclaimer policy Disclaimer Policy.

Compatibility

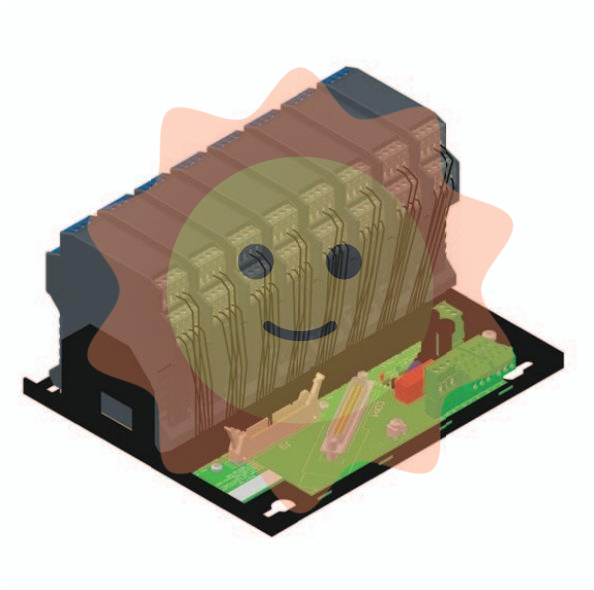

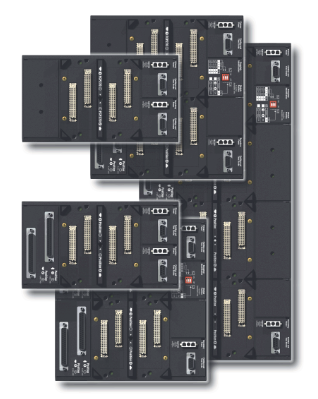

ƒ Compatible with any Series 90-30 CPU except IC693CPU321 and IC693CPU340. Configuration size is limited for CPU311/313/331, as described on the next page.

ƒ Requires release 8.0 CPU firmware. The latest Release 10 is recommended, if available for the particular CPU.

ƒ Requires CIMPLICITY Machine Edition Logic Developer PLC version 3.0 plus the appropriate service pack or special (or a version later than 3.0).

ƒ Not compatible with the VersaPro™, Control, or Logicmaster™ programming software.

ƒ The Series 90-30 Hand-Held Programmer (IC693PRG300) cannot be used to configure this module. New Features The Series 90-30 DeviceNet Master Module allows a Series 90-30 PLC to send and receive I/O data from a DeviceNet network.

Module features include:

ƒ Support for all standard data rates (125K, 250K, 500K)

ƒ Support for 255 bytes input data transfer and 255 bytes output data transfer per slave

ƒ Support for 3972 bytes of input data transfer and 3972 bytes of output data transfer per master

ƒ Support for two I/O connections per Slave - Typically one connection is used for Polled and the other is used for Strobe, Cyclic, or COS

ƒ Support for Poll, Strobe, Cyclic and COS I/O Connections, Fragmented I/O and Explicit Messaging

ƒ Support for Unconnected Message Manager (UCMM) with 1 proxy connection per slave device

ƒ Support for configuration of the global scan rate

ƒ Support for configuration of update rates for Poll and COS/Cyclic on a connection basis

ƒ Support for PLC-application initiated explicit messaging via a COMMREQ

ƒ Master can be configured to operate as a slave simultaneously with master operation

ƒ Configurable fault behavior on loss of communication

ƒ Reports loss or reestablishment of communication with slaves in PLC fault table (configurable)

ƒ Support for 64 network device status bits (note: the bit for the master itself is always zero)

ƒ Firmware update via service port on module

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com