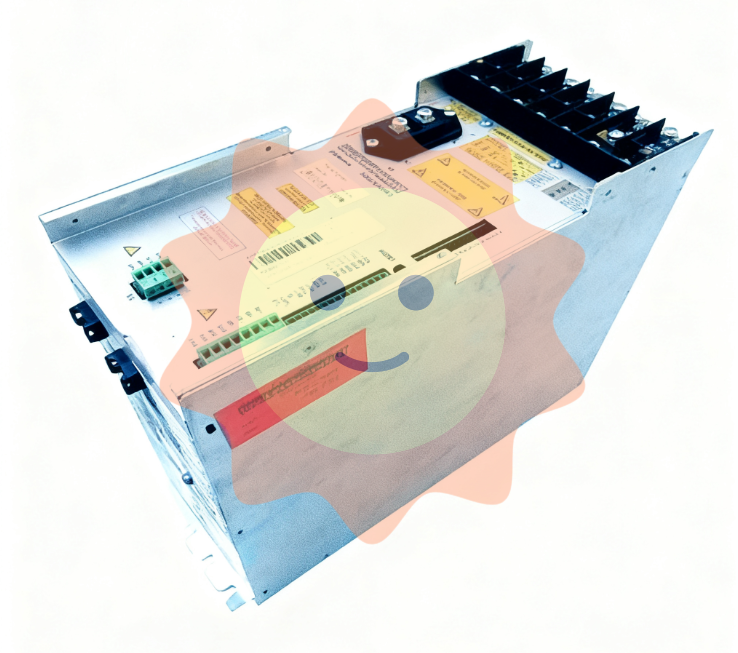

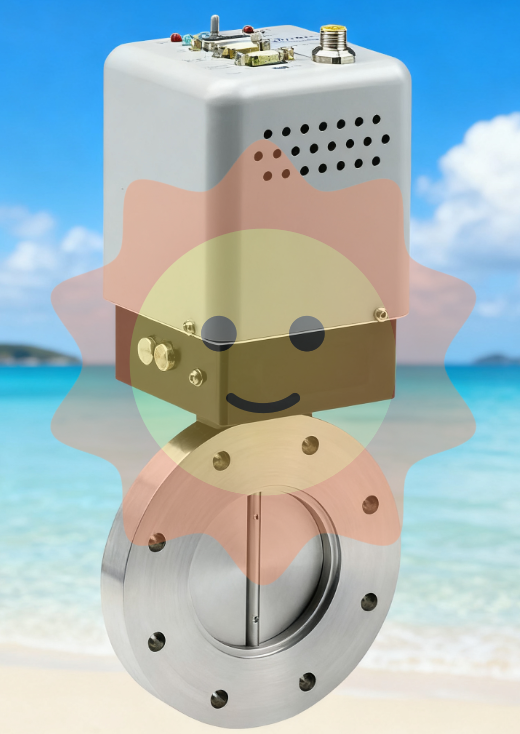

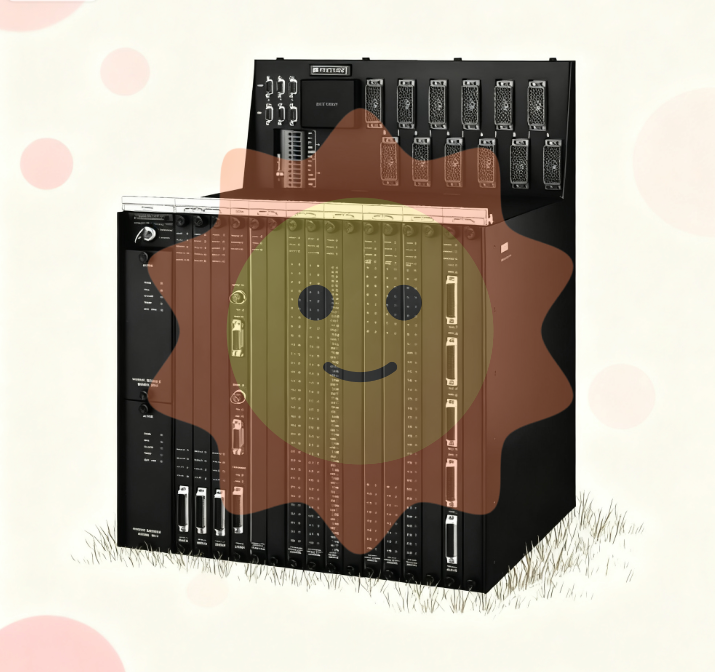

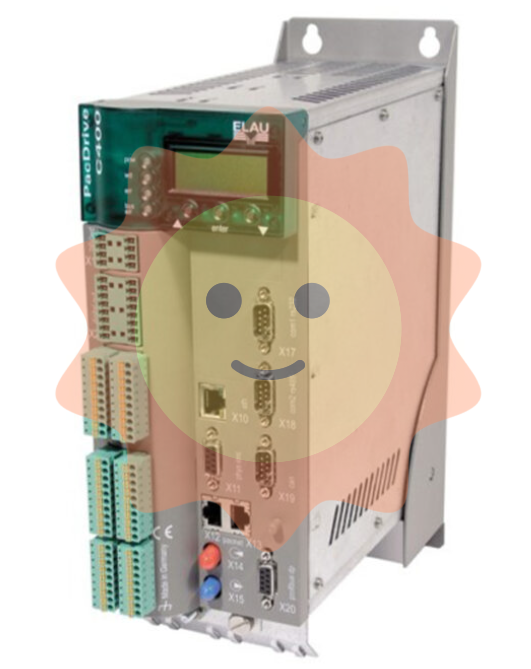

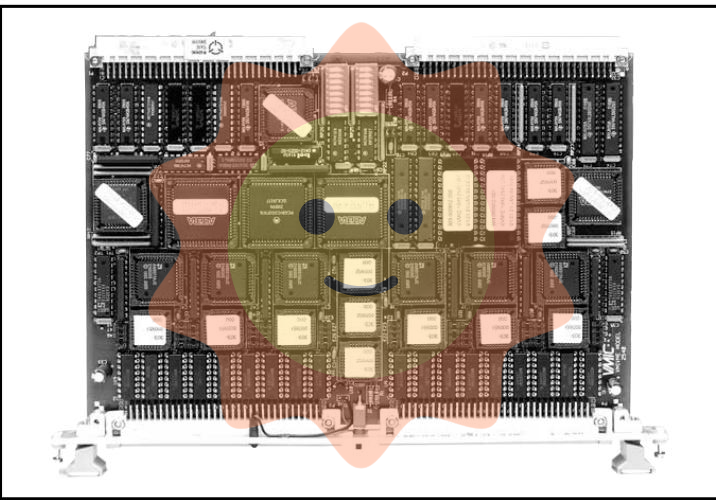

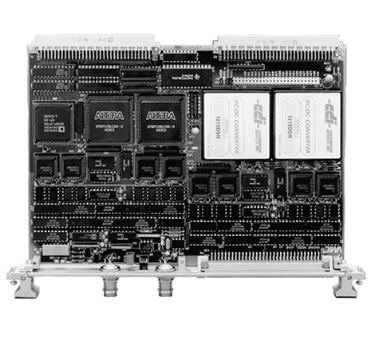

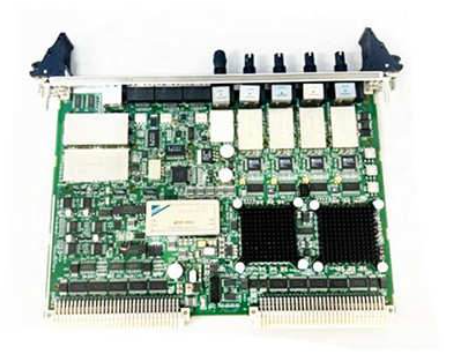

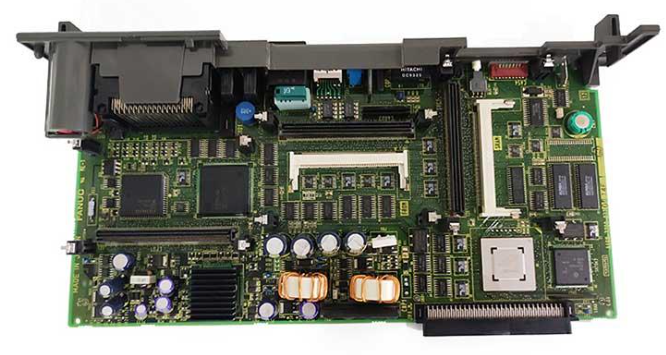

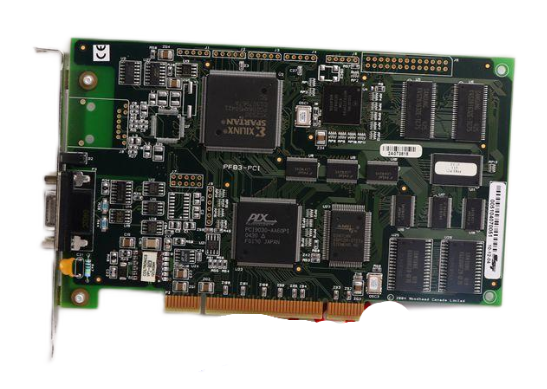

GE 531x301dccafg2 Drive Control Board

GE 531x301dccafg2 Drive Control Board

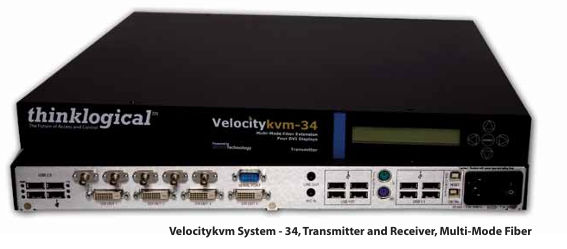

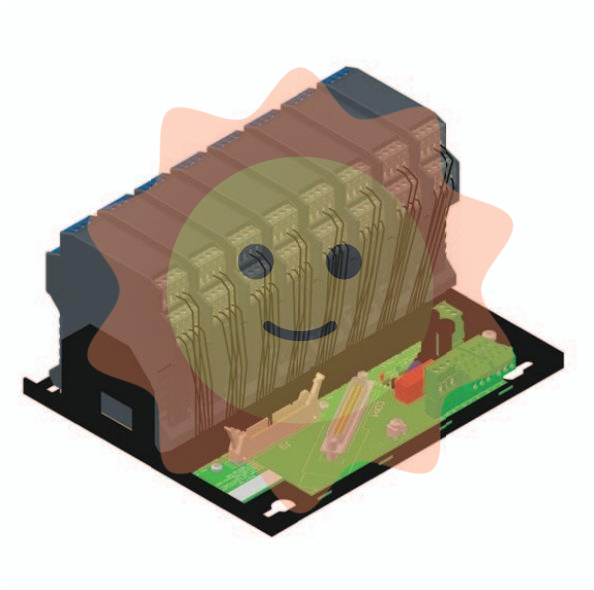

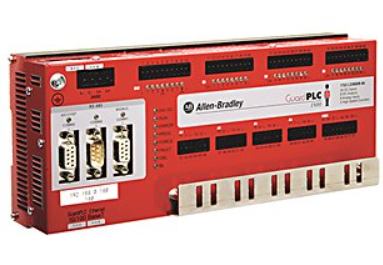

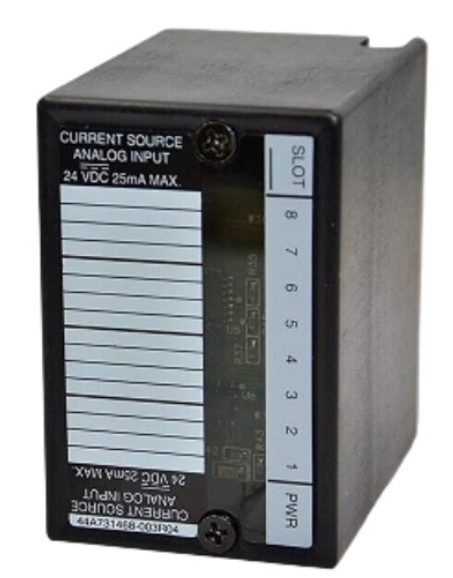

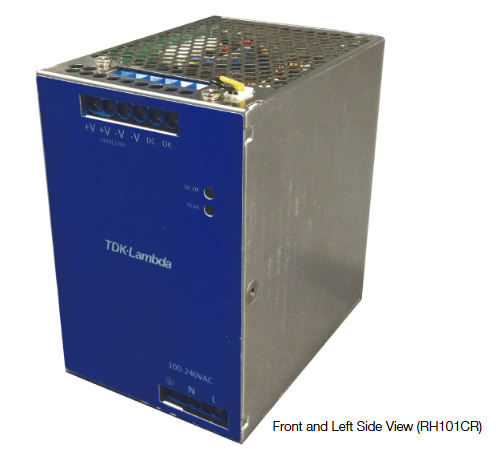

Part Number 531x301dccafg2 Manufacturer General Electric Country of Manufacture As Per GE Manufacturing Policy Series Mark VI/VIe Function Module Availability In Stock531X301DCCAFG2 is a Drive Control Board manufactured and designed by General Electric as part of the Mark V Series used in Drive control systems. An Intel 80186 microprocessor is found on the control processor board. After new software has been downloaded onto the EEPROM, a little push-button switch located on the board can be used to restart the processor. Power Requirements The Mark V panel can take power from various sources.

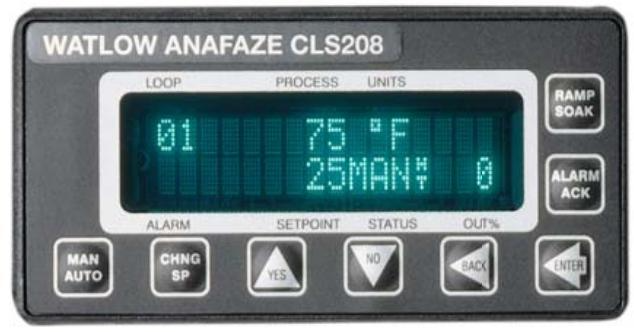

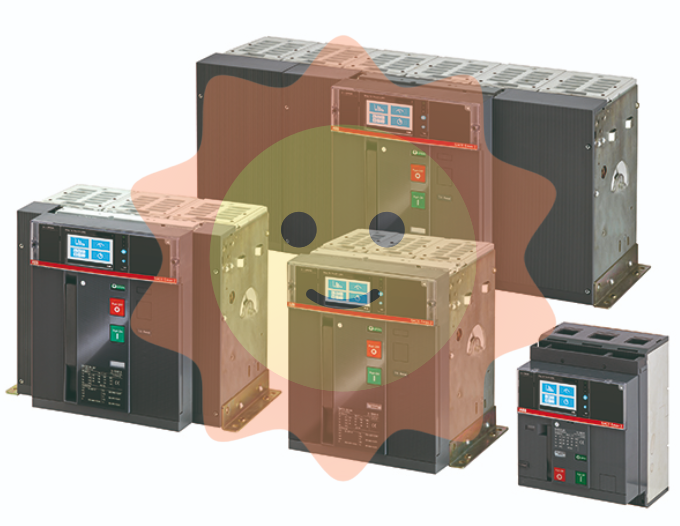

Before entering the Mark V panel, each power input source (two ac and two dc sources) should pass through its own external 30 A 2 pole thermal magnetic circuit breaker. A 125 V dc source and/or up to two 120/240 V ac sources can both be used as power sources. A common 125 V dc panel distribution bus is used to power each power supply board that each core in the panel has. Log Functions Alarms are logged with a 62ms resolution both as they happen and as they clear. The printer records events (turbine operation) with a 62 ms individual time tag resolution, such as engaging the turning gear or closing the generator breaker.

Events can be defined by the user and modified on the fly. On the printer, events (contact inputs) are recorded with unique time tags of 1ms. The event log records each contact input made to the Mark V. Individual contact inputs can be removed from the event log and logging can be turned on or off in the field. The turbine trip analysis has a record in the trip log. Each sample can contain up to 63 parameters, with 3 post-trip samples lasting 3 seconds and 38 pre-trip samples lasting 5 hours. You can print this information or view it on the display. When the unit is restarted, the trip log's freeze is broken, and samples start to replace the memory locations in the log.

Main Functions

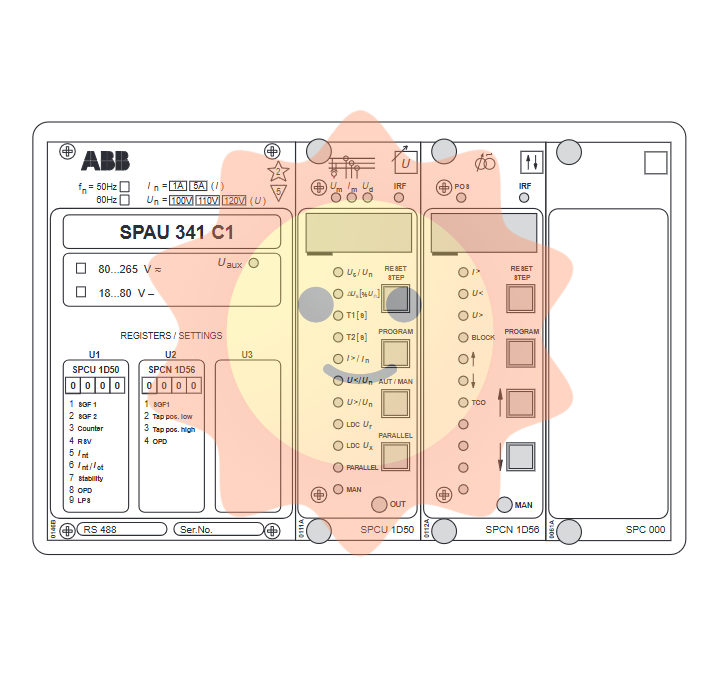

Power system monitoring and control:

The power interface board can be used for power system monitoring and control equipment to ensure the safe, stable and reliable operation of the power system.

Power plant automation:

In the power plant, it can be used to connect and manage the power supply of the mastering system and monitoring equipment to improve the automation level of the power plant.

Power transformer and distribution:

Applicable to substations and distribution stations, it is used to govern the power supply of transformers, circuit breakers and other equipments to ensure the high efficiency of power transmission and distribution.

Industrial Process Mastering:

In manufacturing and chemical workshops, this power interface board can be used for power management of automation systems, inner and control equipment to enhance productivity and safety.

Building Automation:

It can be used in building automation system, power supply to lighting, air conditioning, security equipment, etc., to achieve intelligent management of building equipment.

Railway flag signal system:

In the railway system, it is used in the power management of railway flag signal equipment and control system to ensure the stable operation of railway signal system.

Smart Grid:

In the smart grid, the power interface board can be used to connect and manage the digital power equipment and promote the intelligent development of the power grid.

Traffic Flag Signal System:

In the traffic flag signal system of routes and intersections, it is used to supply power to the flag master and equipment to ensure the normal display of traffic signals.

Aerospace:

In aviation and aerospace, the power interface board can be used in the control system of aircraft and spacecraft to provide stable and reliable power support.

It is suitable for land initiatives, oilfield equipment and other categories, providing power support for various land engineering equipment.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com