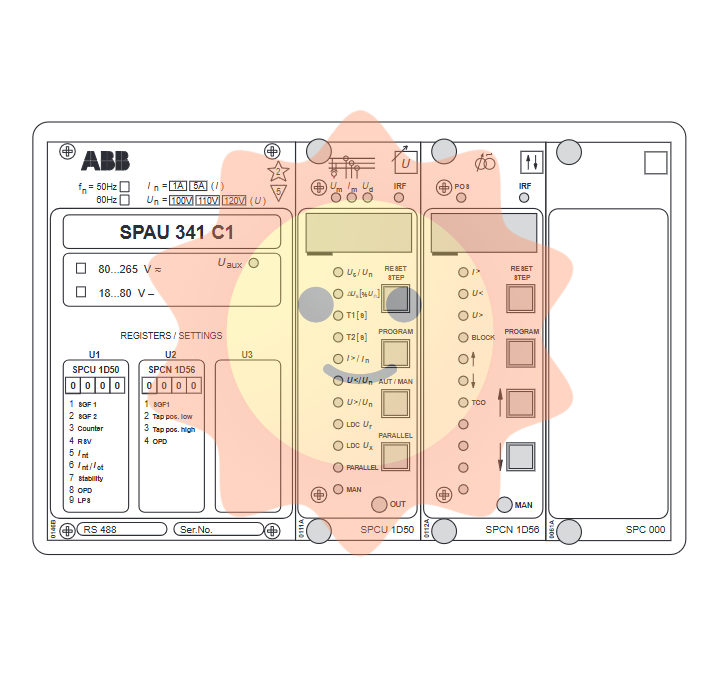

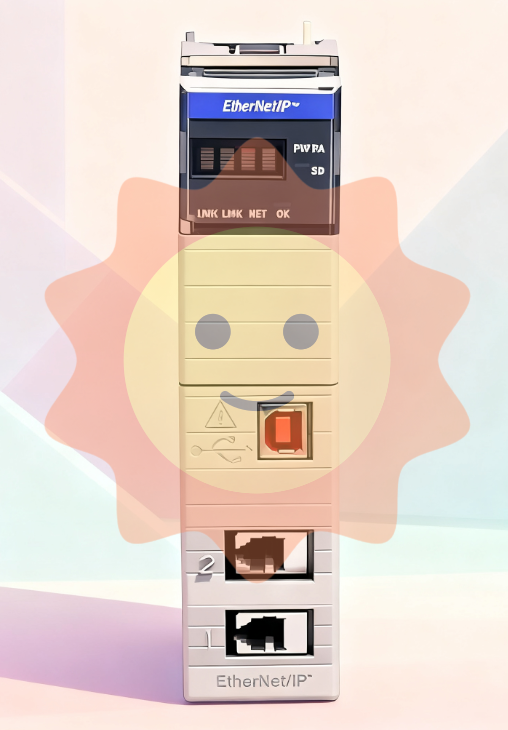

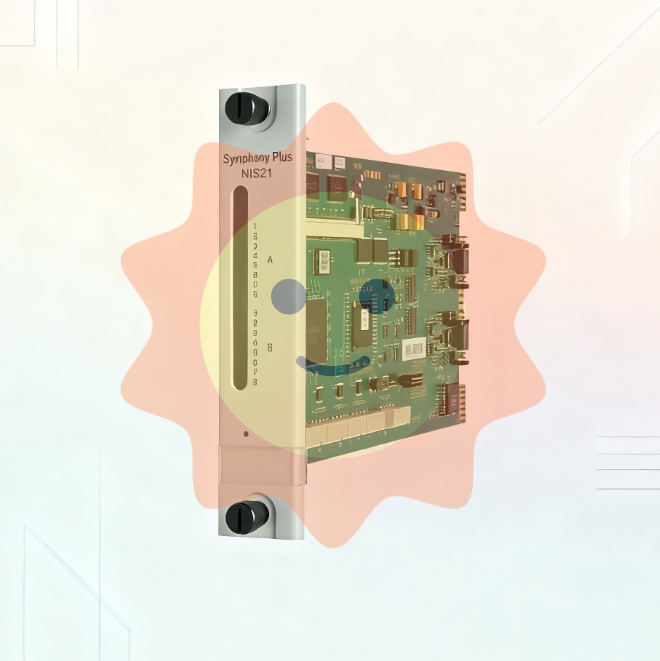

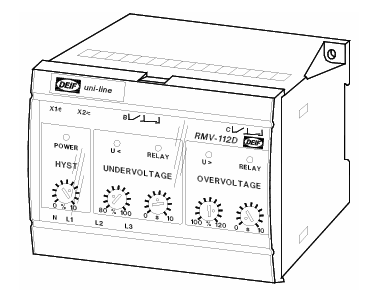

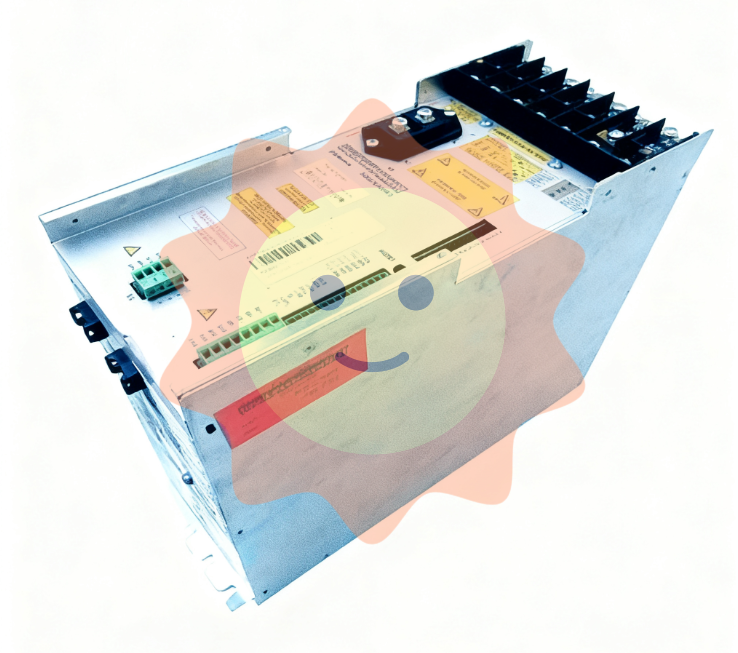

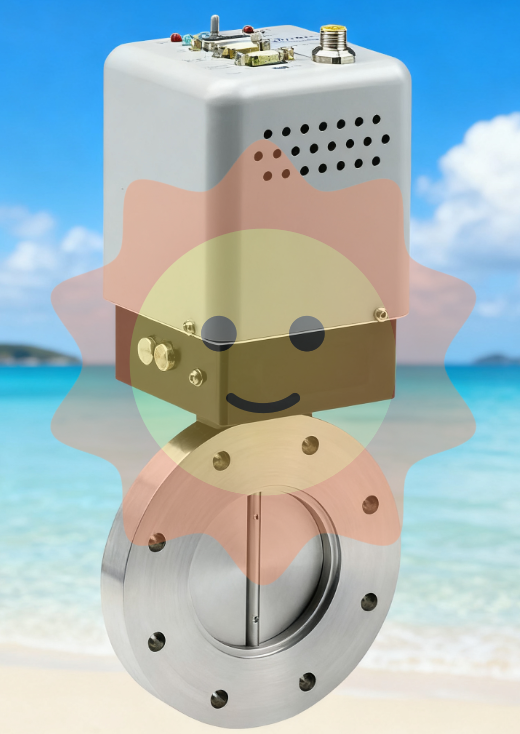

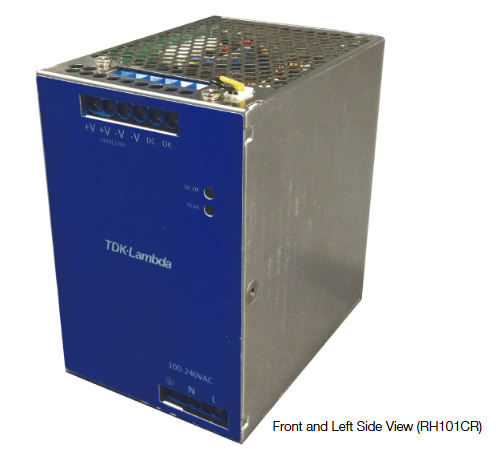

ABB DSQC609 3HAC14178-1 PBSE5117 Power Supply

ABB DSQC609 3HAC14178-1 PBSE5117 Power Supply

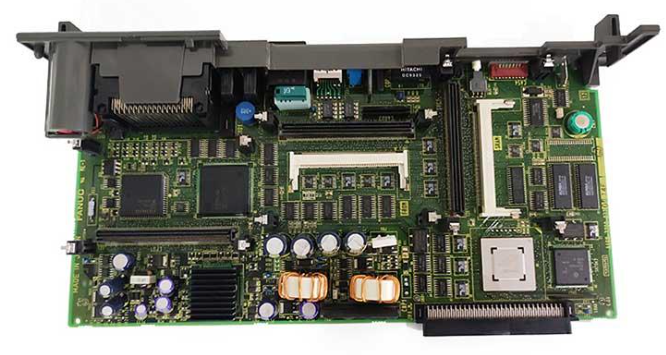

Product Overview

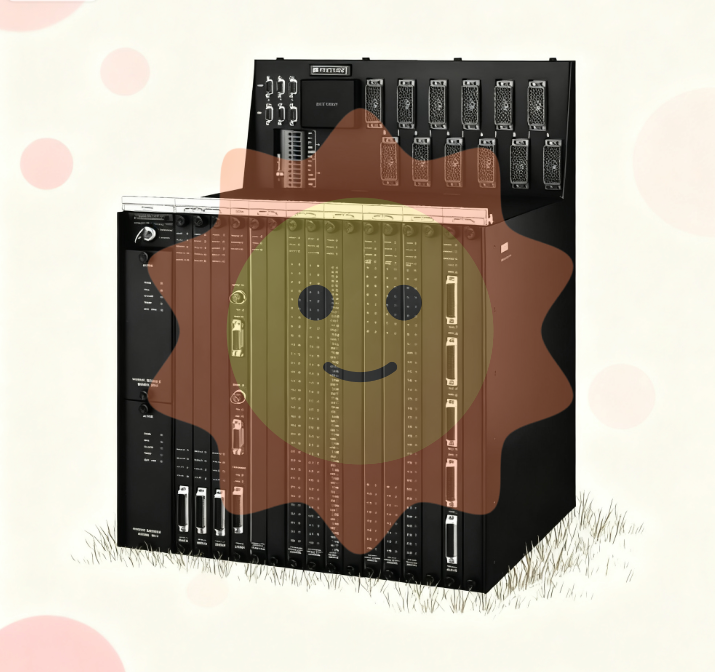

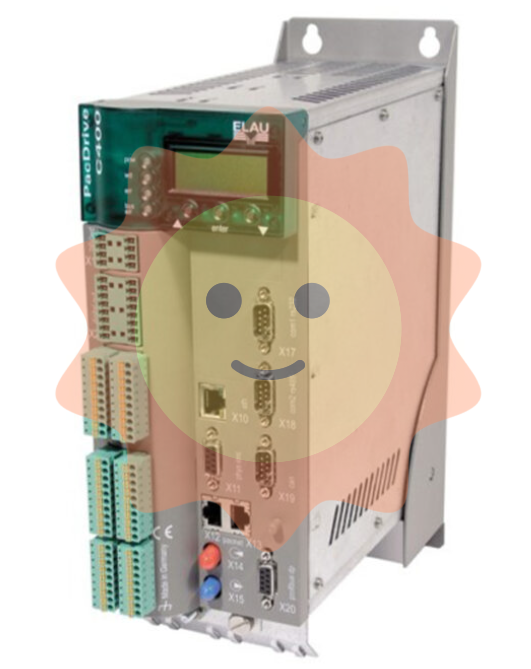

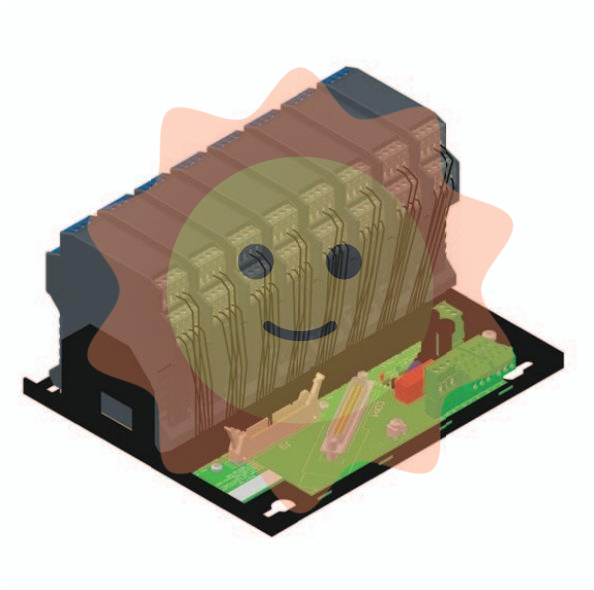

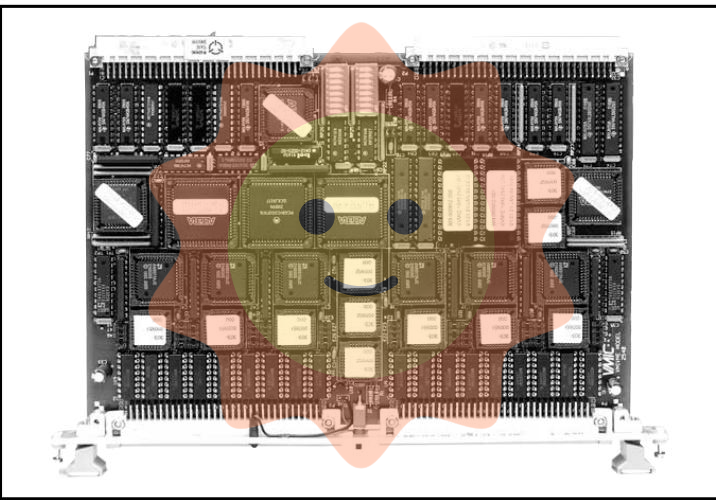

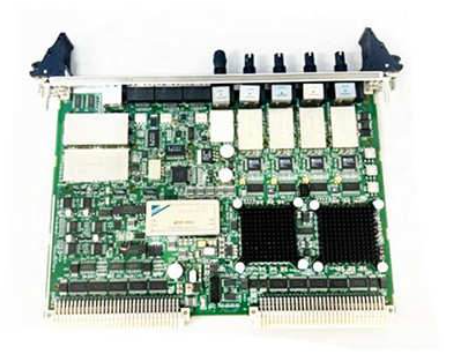

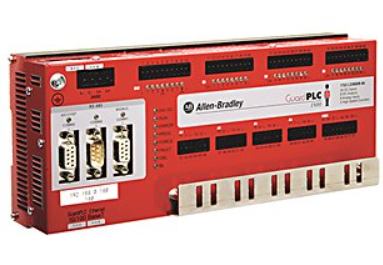

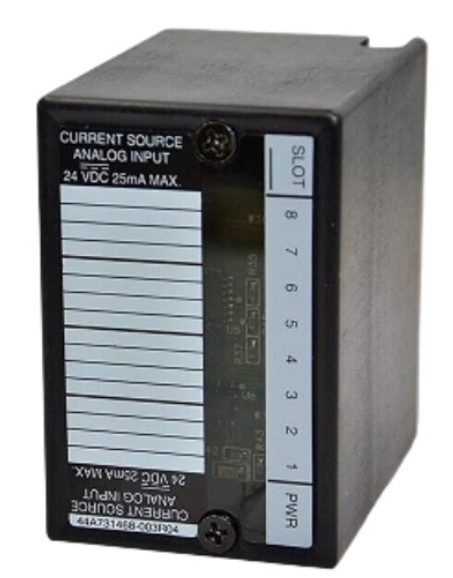

DSQC609 3HAC14178-1 PBSE5117 is a power module from ABB designed for robot control systems. With high performance, reliability and flexibility, the module is able to meet the needs of robot systems for precise control and efficient operation.

Main functions

Power supply function: as a power supply module, DSQC609 3HAC14178-1 PBSE5117 can provide stable and reliable power supply for the robot control system to ensure the normal operation of the system.

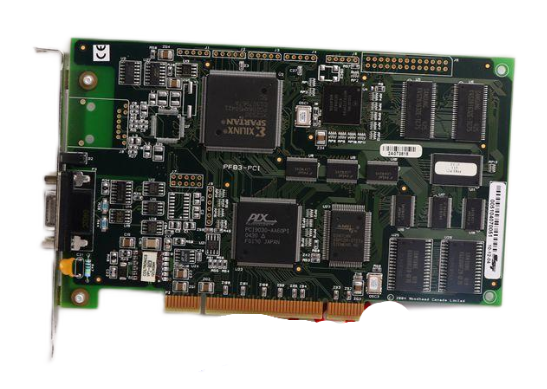

Communication and data exchange: The module has a variety of communication interfaces, such as Ethernet, serial port, etc., which can exchange data and communicate with the robot control system to achieve real-time transmission and processing of information.

Multi-functional input/output: DSQC609 3HAC14178-1 PBSE5117 usually has multiple input and output channels, which are used for connecting various sensors and actuators, as well as interacting data with external devices.

Real-time monitoring: The module is able to monitor the status and data of the connected devices in real time and transmit them to the robot control system for processing and control, ensuring the safety and reliability of the system.

Technical features

High performance: DSQC609 3HAC14178-1 PBSE5117 power supply module adopts advanced technology and design with high performance index, which can meet the demand of robot system for high precision, high speed and high efficiency.

High reliability: the module adopts high-quality components and advanced production technology, with high reliability and stability, capable of stable operation for a long time, reducing failures and downtime.

Easy maintenance: DSQC609 3HAC14178-1 PBSE5117 power supply module is reasonably designed, easy to install, debug and maintain, reducing system maintenance costs and time.

Intelligent control: the module may have certain intelligent control functions, able to perform the corresponding control operations according to the preset conditions, to improve the automation level of the system and the degree of intelligence.

Application Scope

DSQC609 3HAC14178-1 PBSE5117 power supply module is widely used in various ABB robot control systems, such as welding, assembly, handling, painting and other automated production lines. It is suitable for robot application scenarios that require high precision, high reliability and high efficiency, and can provide users with stable and reliable power supply and control means.

Market Price and Availability

Depending on the market situation, the price of DSQC609 3HAC14178-1 PBSE5117 power supply module may vary depending on the supplier, the quantity purchased, the time of purchase and other factors. Also, availability may be affected by market demand, production lead time and other factors. Therefore, it is recommended that users consult multiple suppliers for the latest market price and availability before purchase in order to make an informed purchasing decision.

Precautions

Correct installation: When installing the DSQC609 3HAC14178-1 PBSE5117 power supply module, please make sure that you follow the steps in the product manual to install it correctly and follow the relevant electrical wiring specifications.

Regular maintenance: Regular maintenance and inspection of DSQC609 3HAC14178-1 PBSE5117 power supply module can prolong its service life and keep its performance stable.

Choose regular suppliers: When purchasing, please choose regular and qualified suppliers to ensure the quality of the product and the reliability of after-sales service.

Installation and Maintenance

Environmental Conditions:

Ensure that the module is installed within the recommended temperature and humidity ranges and avoid direct exposure to water, oil, dust or electromagnetic interference.

Power Requirements:

Use a stable power supply to avoid damage to the module from voltage fluctuations.

Signal Cable Connection:

Connect the signal lines correctly to ensure the accuracy and stability of signal transmission.

Software Configuration:

Correctly configure the software parameters of the module according to the system requirements to ensure compatibility with other parts of the control system.

Maintenance and Inspection:

Perform regular maintenance and inspection of the module, including cleaning and checking the contact status of the connectors.

Precautions

Operator Training:

Operators should receive proper operation and maintenance training to avoid malfunctions or safety accidents caused by incorrect operation.

Technical Documentation and Safety Guidelines:

The technical documentation and safety guidelines provided by the manufacturer should be read and understood in detail before installation and use.

Compliance with safety regulations:

Observe all relevant safety procedures to ensure personal safety, especially when handling high-pressure or high-speed rotating equipment.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com