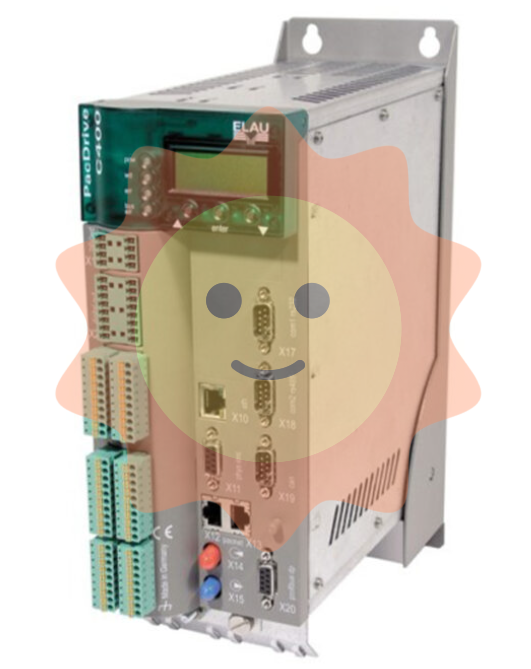

BENTLY 1900/27 Vibration Monitor

BENTLY 1900/27 Vibration Monitor

Description

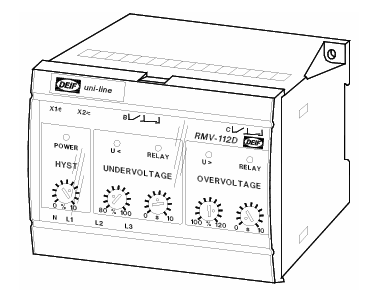

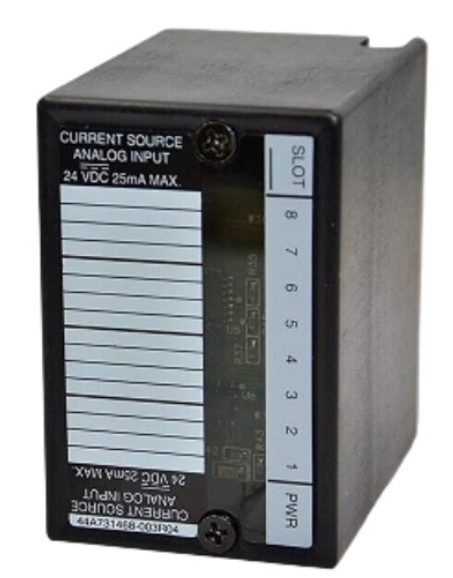

The 1900/27 is a single-channel, stand-alone, locally mounted vibration monitor. It can be used as a stand-alone machinery protection device, suitable for general-purpose or some essential machinery and provides a built-in 4-20 mA interface for trending the monitored parameter in plant control and automation systems. The 1900/27 accepts a single transducer input from compatible Trendmaster® 2000 accelerometers, conditions the signal into peak velocity units, and provides local display and status indication as well as alarm relay contact outputs for connection to an external annunciator.

By using an optional Rack Buffered Output Transducer Interface Module (TIM), the 1900/27 can also be used in conjunction with our Trendmaster 2000 system. It allows the user to apply machinery protection capabilities to all (or selected) seismic vibration points of the Trendmaster 2000 system.

Specifications

AC Voltage:85 to 264 Vac

DC Voltage:110 to 370 Vdc

Current Draw:60 mA. typ. 120 mA max.

Frequency:47 Hz to 440 Hz, or DC.

Metric Units:50.8 mm/s zero-to-peak

LED Indicators

OK:One constant ON green LED indicates OK condition of monitor, transducers, and field wiring. Constant OFF indicates NOT OK condition. OK LED flashing at 2 Hz indicates monitor has been NOT OK, but is now OK

Alert:One yellow LED indicates an Alert condition. Flashing at 2 Hz indicates an Alert condition has occurred and gone away. (Only occurs when the Alert relay is configured as nonlatching.)

Danger:One of the two red LEDs indicates a Danger condition. Flashing at 2 Hz indicates a Danger condition has occurred and gone away. (Only occurs when the Danger relay is configured as nonlatching.)

Environmental Limits

Operating Temperature:-20°C to +70°C (-4°F to +158°F)

Storage Temperature:-30°C to +90°C (-22°F to +194°F)

Relative Humidity:To 95%, non-condensing

Dimensions

Height x Width x Depth:132 mm x 132 mm x 71.1 mm (5.20 in x 5.20 in x 2.80 in)

Weight:400 g (0.85 lb).

Our Main Brands

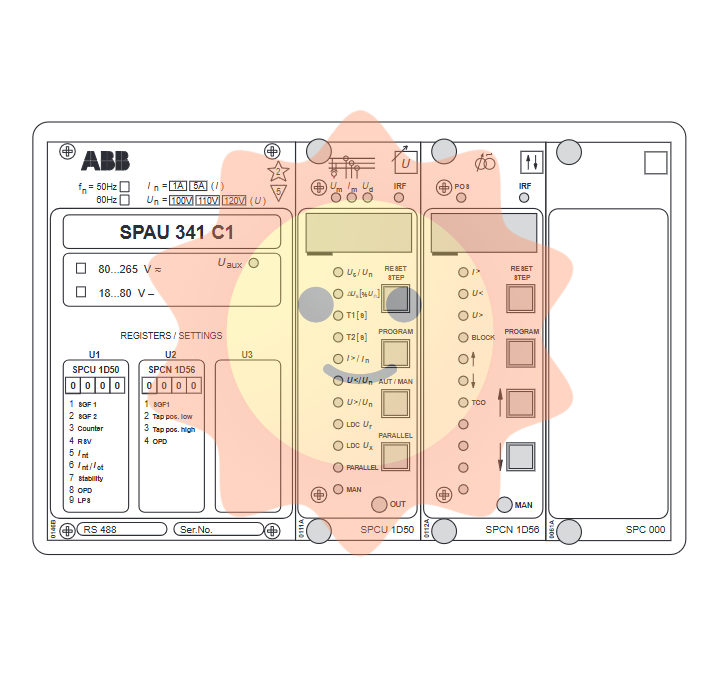

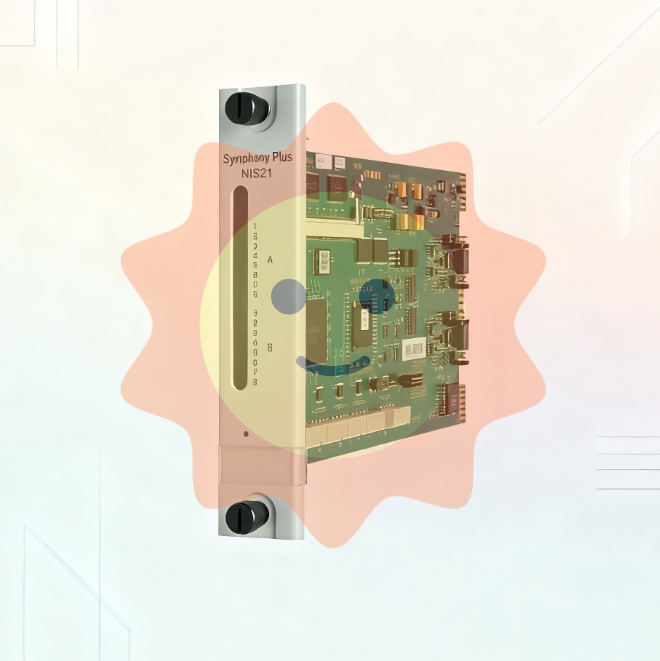

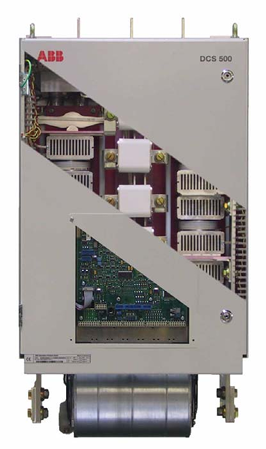

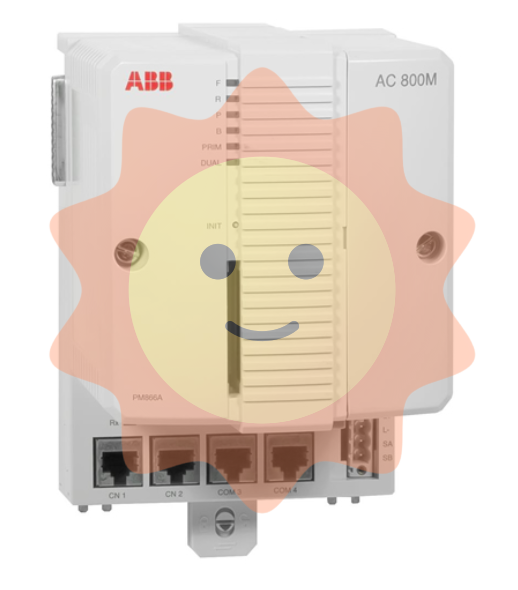

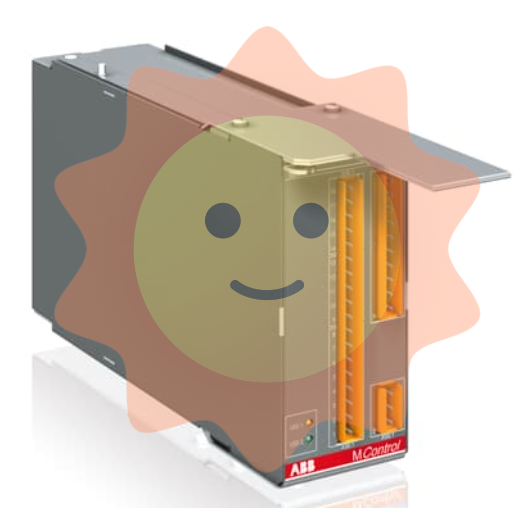

· - ABB Advant-800xA,Advant OCS,Bailey Infi 90 and Net 90,H&B Freelance 2000,DSQC Robots,IGCT / IGBT

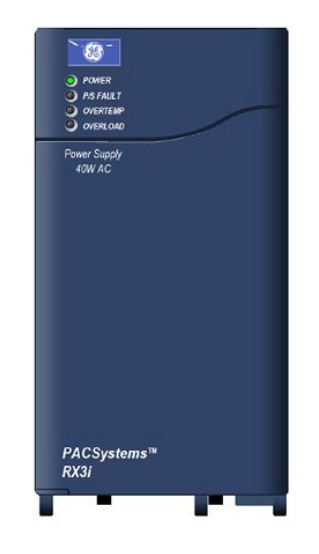

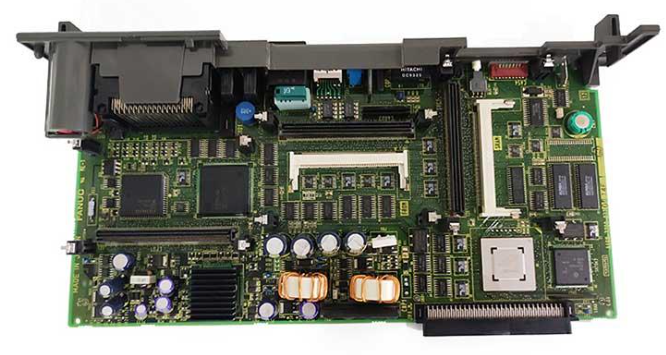

· - GE General Electric Field Control, Genius I/O, QuickPanel, RX3i PacSystem, Series 90, Series 90, Series VersaMax

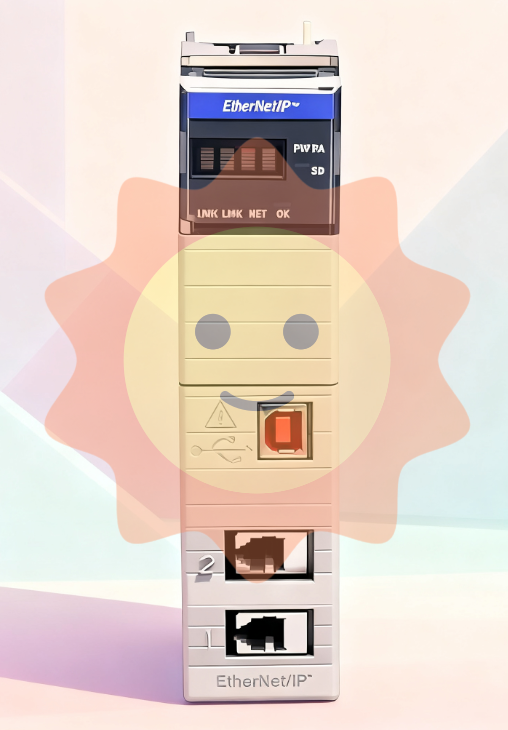

· - Allen Bradley Allen-Bradley SLC500, MicroLogix, CompactLogix, ControlLogix, PLC-5, Panel View,

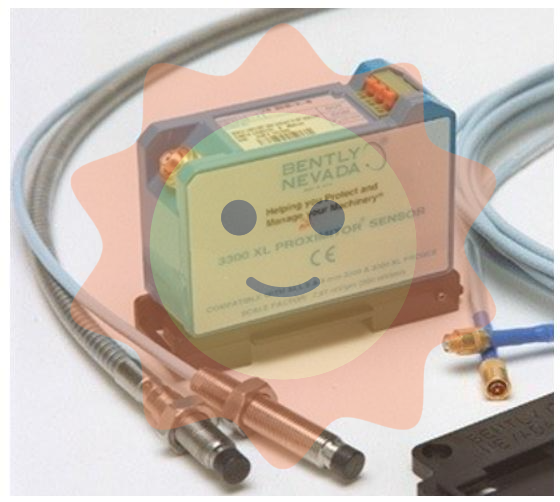

· - Bently Nevada 3300 System, 3500 System

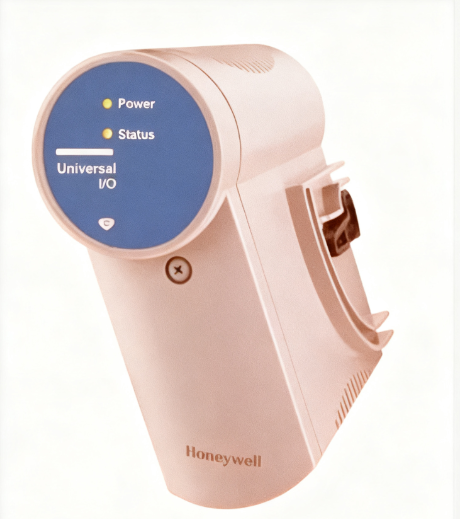

· - Honeywell 7800 Series, FSC, IPC, Mxopen, TDC 2000, TDC 3000, Experion PKS(C200,C300)

· - Yokogawa Centum CS - Centum VP, Centum XL - micro XL, FA-M3, ProSafe-PLC

- Ovation, Foxboro, EPRO, Emerson DeltaV, Fuji, Siemens, HIMA, Prosoft, Invensys Triconex, ICS TRIPLEX, Woodward, Bachmann, Schneider

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com