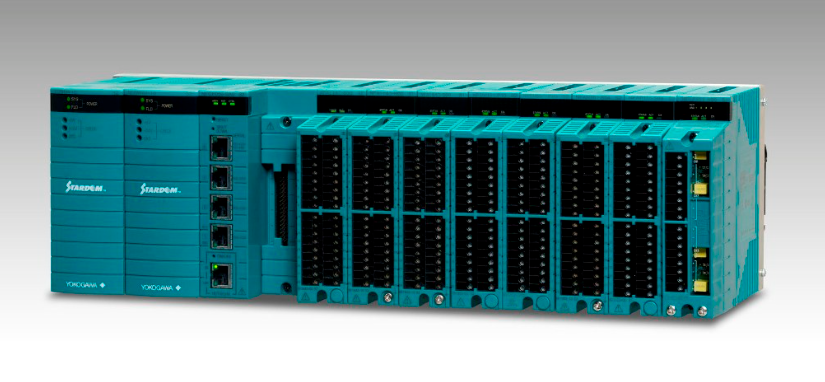

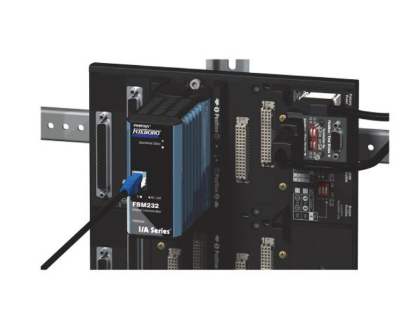

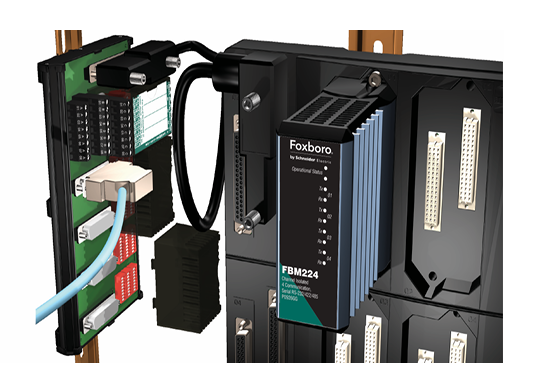

The FOXBORO FBM201D discrete input module is a specialized signal acquisition component in the Foxboro I/A Series Distributed Control System (DCS) Fieldbus Module (FBM) series, focusing on precise collection and reliable transmission of discrete signals (switch on/off, equipment start/stop status, etc.) in industrial sites. As a key bridge connecting on-site sensors/switches and system control layers, this module is based on industrial grade microprocessors and adopts high-density channel design. It can simultaneously access multiple discrete signals and perform real-time processing, effectively simplifying the system wiring and configuration process. It has strong anti-interference ability and environmental adaptability, and can work stably in high-temperature and high electromagnetic interference scenarios in industries such as petrochemicals and power. It provides real and accurate on-site status data for control systems and is an important hardware support for industrial production process monitoring and safety interlocking.

FOXBORO FBM201D Discrete Input Module

Product Overview

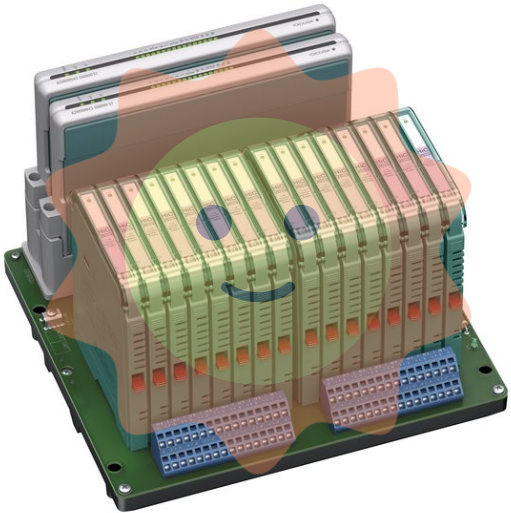

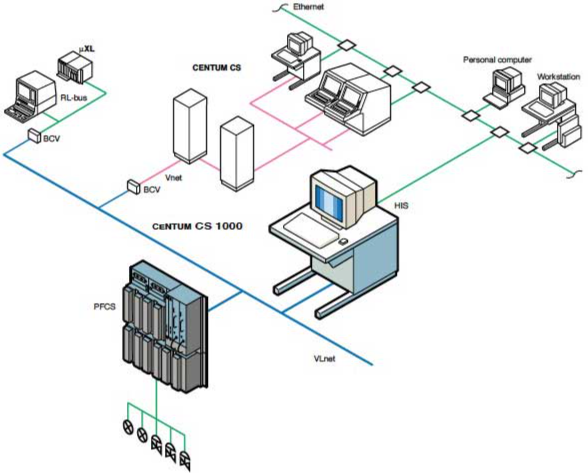

The FOXBORO FBM201D discrete input module is a specialized signal acquisition component in the Foxboro I/A Series Distributed Control System (DCS) Fieldbus Module (FBM) series, focusing on precise collection and reliable transmission of discrete signals (switch on/off, equipment start/stop status, etc.) in industrial sites. As a key bridge connecting on-site sensors/switches and system control layers, this module is based on industrial grade microprocessors and adopts high-density channel design. It can simultaneously access multiple discrete signals and perform real-time processing, effectively simplifying the system wiring and configuration process. It has strong anti-interference ability and environmental adaptability, and can work stably in high-temperature and high electromagnetic interference scenarios in industries such as petrochemicals and power. It provides real and accurate on-site status data for control systems and is an important hardware support for industrial production process monitoring and safety interlocking.

Specification parameters

Core functionality

Multi channel discrete signal acquisition, supporting dry/wet contact signal input, with channel level fault diagnosis function

Input channel specifications

Number of channels: 16 channels/32 channels available for selection; Input type: PNP/NPN polarity optional, supporting dry contacts (passive) and wet contacts (active); Rated input voltage: 24VDC (standard), compatible with 12VDC/48VDC

Input signal performance

Input current: Wet contact 3-15mA, dry contact ≤ 1mA; Response time: ≤ 0.5ms (signal rising/falling edge); Input impedance: ≥ 10k Ω

Diagnostic function

Support channel open circuit, short circuit, and overvoltage fault diagnosis, with signal over range alarm; Module self diagnosis (power, communication, hardware faults)

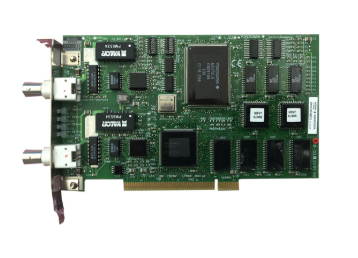

communication interface

Compatible with Foxboro I/A Series backplane bus and supports high-speed synchronization with system controllers; Communication speed: 1Mbps, data transmission delay ≤ 1ms

working power supply

System bus power supply: 5VDC ± 5% (logic power supply), 24VDC ± 10% (signal circuit power supply); Maximum power consumption ≤ 8W (32 full loads)

environmental parameters

Working temperature: -10 ℃ -65 ℃; Storage temperature: -40 ℃ -85 ℃; Relative humidity: 5% -95% (no condensation); Vibration level: IEC 60068-2-6, 5g peak; Impact level: IEC 60068-2-27, 15g peak value

Physics and Authentication

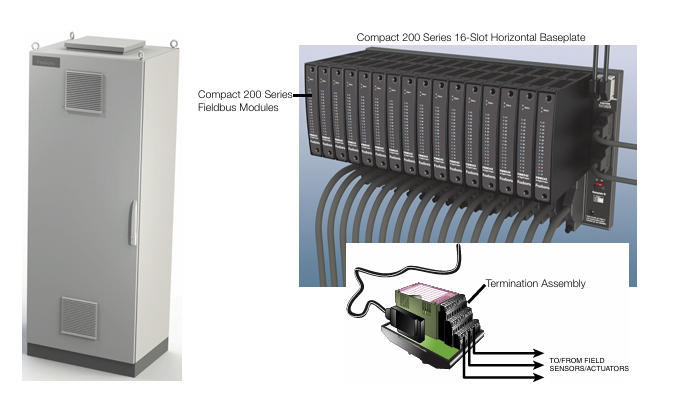

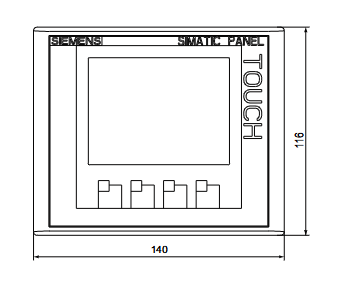

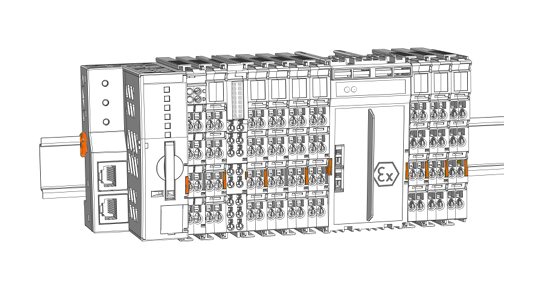

Size: 160mm (width) x 100mm (height) x 220mm (depth), supports I/A Series standard rack mounting; Compliant with UL 61010-1, IEC 61326-1, ATEX Zone 2 explosion-proof certification

Performance characteristics

-High density and high responsiveness: adopting a 32/16 high-density channel design, a single module can access signals from multiple on-site devices, saving rack space; Signal response time ≤ 0.5ms, capable of accurately capturing rapidly changing discrete signals, such as the limit switch status of high-speed production lines.

-Excellent anti-interference performance: Each input channel is independently optically isolated, with an isolation voltage of ≥ 2500VAC, effectively blocking interference between channels and between modules and systems; Built in multi-level EMC filtering circuit, compliant with IEC 61000-4 electromagnetic compatibility standard, to resist industrial field surges and pulse group interference.

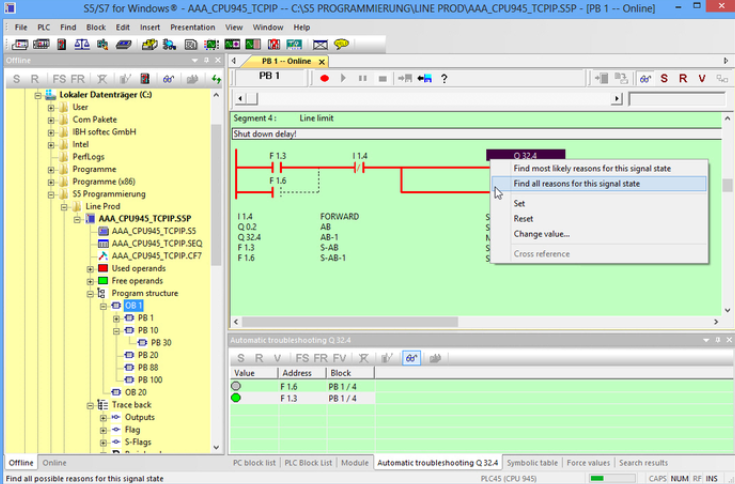

-A comprehensive fault diagnosis system: Channel level fault diagnosis can identify abnormalities such as open circuit, short circuit, overvoltage in real time, and upload fault information to the system HMI through the backplane bus, marking the specific fault channel; The module self diagnostic function monitors the power, communication, and hardware status to ensure that faults can be quickly located.

-Deep system compatibility: designed specifically for Foxboro I/A Series DCS, seamlessly integrated with system controllers and configuration software (Control Builder), supporting online configuration of channel signal types and alarm thresholds, and parameter modification can be completed without interrupting system operation.

-High reliability and easy maintenance: Supports hot swappable function, no downtime required for module replacement, ensuring production continuity; Equipped with channel status indicator lights (each independent LED), visually displaying signal on/off and fault status, simplifying on-site inspection and maintenance work.

Working principle

The FOXBORO FBM201D module uses the core process of "signal access preprocessing conversion transmission diagnosis" to achieve precise acquisition and reliable upload of discrete input signals. The specific mechanism is as follows:

1. Signal access and conditioning: The on/off signals of on-site discrete devices (such as limit switches, proximity sensors, and device operating status contacts) are connected to the corresponding channels of the module through wiring terminals. The dry contact signal is powered by the internal excitation power of the module, and the wet contact signal is directly connected; The signal conditioning circuit filters and limits the input signal to remove high-frequency interference and peak voltage.

2. Isolation and Conversion: The conditioned signal is electrically isolated by a photoelectric isolator to prevent strong electrical interference from being transmitted to the system side on site; Subsequently, the analog signal is converted into a standard digital logic signal (0/1, corresponding to signal disconnection/connection) by a high-speed comparator, and transmitted to the module core microprocessor.

3. Data processing and communication: The microprocessor performs real-time scanning and logical judgment on the digital signals of each channel, integrating channel status data; Establish synchronous communication with the system controller through the I/A Series backplane bus, upload the collected discrete data to the controller, and provide on-site data support for control logic operations.

4. Fault monitoring and feedback: The microprocessor monitors the amplitude of each channel signal, loop current, and its own working status in real time. When an open circuit (current of 0), short circuit (current exceeding the standard), or overvoltage is detected, a fault identifier is immediately generated, uploaded to the HMI through the communication bus, and the corresponding channel fault indicator light is lit, triggering the system alarm at the same time.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com