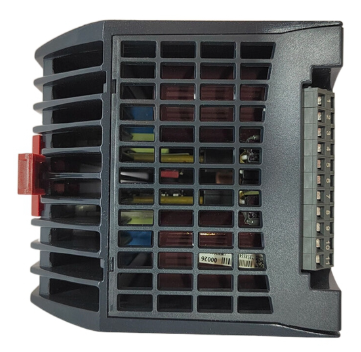

ABB 3BHL000986P7000 (model identification includes LXN1604-6) is a high reliability switching power module designed specifically for industrial automation control systems. Its core function is to provide stable and pure DC power supply to upper level controllers, I/O modules, sensors, and actuators. This module serves as a key power unit for ABB industrial control systems (such as AC 800M and ACS series frequency converter matching systems), with a wide input voltage range, efficient energy conversion, and comprehensive protection mechanisms. It can continuously output stable voltage in complex industrial environments, providing core power support for the continuous and safe operation of automation systems. It is widely used in fields such as power, metallurgy, and chemical engineering that require strict power supply reliability.

ABB 3BHL000986P7000 LXN1604-6 POWER SUPPLY

Ordering

Core Credit:0.00

Customs Tariff Number:85044083

Invoice Description:POWER SUPPLY

Made To Order:No

Minimum Order Quantity:1 piece

Order Multiple:1 piece

Quote Only:No

Selling Unit of Measure:piece

Dimensions

Product Net Weight:2.96 kg

Product Net Depth / Length:194 mm

Product Net Height:138 mm

Product Net Width:113.6 mm

Package Level 1 Depth / Length:194 mm

Package Level 1 Height:138 mm

Package Level 1 Width:113.6 mm

Package Level 1 Units:1 piece

Technical

Frame Size:Spare_Parts

Environmental

WEEE Category:Product Not in WEEE Scope

External Classifications and Standards

UNSPSC:39121007

Basic overview of module

ABB 3BHL000986P7000 (model identification includes LXN1604-6) is a high reliability switching power module designed specifically for industrial automation control systems. Its core function is to provide stable and pure DC power supply to upper level controllers, I/O modules, sensors, and actuators. This module serves as a key power unit for ABB industrial control systems (such as AC 800M and ACS series frequency converter matching systems), with a wide input voltage range, efficient energy conversion, and comprehensive protection mechanisms. It can continuously output stable voltage in complex industrial environments, providing core power support for the continuous and safe operation of automation systems. It is widely used in fields such as power, metallurgy, and chemical engineering that require strict power supply reliability.

Core Features and Advantages

1. Wide input range and stable output performance

The module adopts a wide AC input design, usually supporting an input voltage range of 85V~264V AC, which can adapt to different regional power grid voltage standards and on-site voltage fluctuation scenarios, without the need for additional voltage conversion equipment. Its output voltage accuracy is extremely high, with a typical value of 24V DC (or specific customized output voltage) and voltage ripple ≤ 100mV. It can effectively suppress the fluctuation of output voltage, provide a pure power supply environment for sensitive electronic devices (such as high-precision I/O modules and microprocessors), and avoid equipment misoperation or data acquisition errors caused by unstable voltage.

2. Efficient energy-saving and low loss design

The module is equipped with advanced switching power supply topology and high-efficiency power devices (such as MOSFET, IGBT), with an energy conversion efficiency of over 90%, significantly reducing power loss and module self heating. Compared to traditional linear power supplies, its temperature rise during full load operation is reduced by 15% to 20%, which not only reduces energy consumption costs in industrial sites, but also extends the service life of modules, and reduces the heat dissipation pressure of control cabinets, without the need for additional high-power cooling fans.

3. Comprehensive protection mechanism ensures safe operation

To cope with various power supply abnormal risks in industrial sites, the module integrates multiple protection functions, including input overvoltage/undervoltage protection, output overvoltage protection, overcurrent protection, short circuit protection, and over temperature protection. When abnormal situations such as sudden rise and fall of grid voltage, load short circuit, and poor module heat dissipation occur, the module can trigger protection actions within milliseconds to avoid damage to itself and downstream equipment by shutting down the output or limiting the current; After troubleshooting, some models support automatic restoration of output function, reducing manual intervention costs.

4. High reliability and adaptability to harsh environments

The module hardware adopts industrial grade component selection, undergoes strict environmental stress screening and reliability testing, and has a wide temperature working range (typical values of -20 ℃~+70 ℃), anti vibration (in accordance with IEC 60068-2-6 standard), anti impact and anti dust characteristics. Its internal circuit is treated with moisture-proof and anti-corrosion coatings, which can operate stably for a long time in harsh environments such as humid and dusty metallurgical workshops and chemical plants, with an average time between failures (MTBF) of over 100000 hours.

5. Convenient installation and status monitoring

The module adopts a 35mm standard DIN rail installation method, with a compact structure (typical dimensions are 120mm × 80mm × 60mm, subject to the actual product), and can be flexibly embedded in industrial control cabinets, saving installation space. The front of the module is equipped with LED status indicator lights, which clearly display the working status of "power normal", "output overcurrent", "over temperature fault", etc. The operation and maintenance personnel can quickly judge the operation status of the module through the indicator lights, shortening the troubleshooting time. Some models support dry contact fault signal output and can be connected to the upper control system to achieve remote fault alarm.

Applicable scenarios

The ABB 3BHL000986P7000 LXN1604-6 power module, with its high stability, reliability, and comprehensive protection functions, is widely used in industrial fields that require strict power supply quality. Its core application scenarios include:

-Power system automation: used for power supply in substations and distribution automation systems, providing stable power supply for PLC controllers, relay protection devices, intelligent instruments and other equipment, ensuring the continuous operation of power dispatch and monitoring systems.

-Metallurgy and Steel Industry: Suitable for control systems of steelmaking furnaces and steel rolling production lines, supplying power to temperature sensors, hydraulic actuators, and I/O modules to resist harsh environmental impacts such as high temperatures and vibrations in workshops.

-Chemical and Petrochemical Industry: Applied to chemical reaction kettle control units, oil and gas pipeline monitoring systems, providing safe power supply for explosion-proof sensors and valve controllers, meeting the explosion-proof and reliability requirements of chemical sites.

-Manufacturing automation production line: provides centralized power supply for PLC, servo drives, and visual inspection equipment in automated assembly lines and robot workstations, ensuring the stability of production pace and equipment coordination accuracy.

-Rail transit auxiliary system: used for signal control boxes and environmental monitoring systems in subways and light rails, adapted to voltage fluctuations and electromagnetic interference environments in rail transit scenarios, ensuring the reliability of signal transmission and equipment control.

Installation and usage precautions

1. Module installation should follow the principle of "vertical installation", ensuring that the heat dissipation holes are unobstructed, leaving at least 5cm of heat dissipation space around the module, avoiding installation in close proximity to high-power heating devices (such as frequency converters), and preventing overheating protection triggered by excessive temperature rise.

2. Before wiring, the input power must be disconnected, and the input (L, N, PE) and output (+24V, 0V) terminals must be strictly distinguished to avoid reverse polarity or short circuit of input and output. After wiring is completed, a multimeter should be used to confirm the correctness of the circuit.

3. The input power circuit needs to be equipped with circuit breakers of appropriate specifications (recommended to select according to 1.2-1.5 times the rated input current of the module), and the output end can be equipped with fuses according to the load distribution to achieve graded protection.

4. The protective grounding terminal (PE) of the module must be reliably grounded with a grounding resistance of ≤ 4 Ω to enhance anti-interference ability and ensure personal safety. Especially in humid or dusty environments, the integrity of the grounding circuit needs to be checked regularly.

5. During the operation of the module, if the fault indicator light is on, the input power should be disconnected first, and the load should be checked for short circuit and abnormal input voltage. After troubleshooting, the power should be restored. It is forbidden to forcefully run the module until the fault is resolved.

6. In daily operation and maintenance, regularly clean the dust and debris on the surface of the module, check whether the wiring terminals are loose, and whether the LED indicator light status is normal; Before reusing modules that have been idle for a long time, insulation testing should be conducted to confirm that there is no risk of leakage before connecting them to the system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-