Kollmorgen 603-AS-BV - Servo Drive

Product positioning: Kollmorgen 603-AS-BV servo drive is not a universal product, but specifically designed for industrial scenarios with strict requirements for motion accuracy, dynamic response, and load adaptability. The original intention of its design is to solve the driving control problems in complex working conditions such as high-speed start stop, multi axis synchronization, and high-precision positioning. It is compatible with multiple servo motors under Kollmorgen (such as AKM series permanent magnet synchronous motors) and also compatible with some third-party standard motors, providing equipment manufacturers with flexible selection space.

From an application level perspective, this driver is mainly aimed at the mid-range to high-end industrial automation market, covering areas such as semiconductor equipment, precision machine tools, packaging machinery, printing equipment, robots, etc. It is particularly suitable for scenarios that require "high torque density+fast dynamic adjustment", such as precise positioning of semiconductor wafer handling mechanisms, high-speed and smooth operation of machine tool spindles, etc.

Core technical parameters and specifications

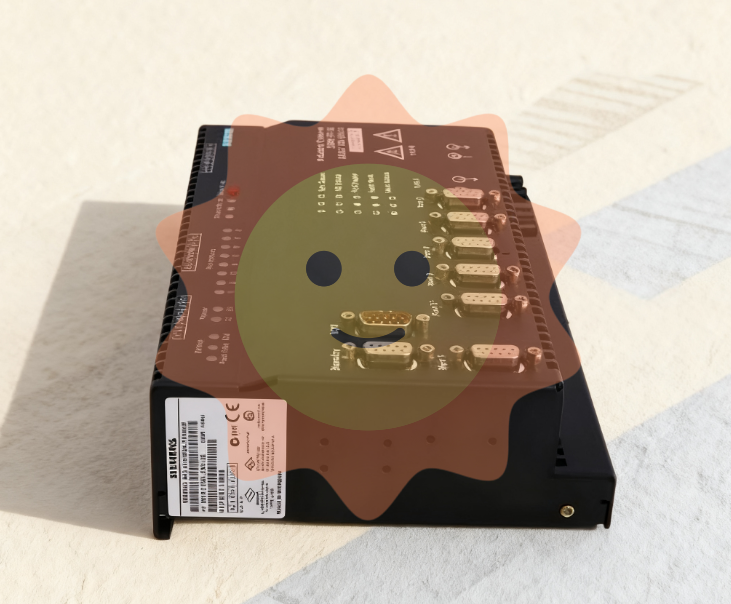

Kollmorgen 603-AS-BV belongs to the SERVOSTAR 600 series digital servo drive, designed specifically for high-precision motion control. The key parameters include:

Power range: covering 0.08 kW to 19.8 kW, suitable for industrial scenarios with various power requirements;

Rated voltage: 480V AC input, meeting industrial grade high voltage drive standards;

Certification standard: UL certification ensures compliance in the North American and global markets;

Compatibility: Supports universal servo motors and can seamlessly integrate with B series brushless motors under Kollmorgen to form high-performance motion control systems.

The driver adopts a compact design, integrating plug-in connectors and flexible communication interfaces, simplifying the installation process and improving system reliability. Although manufacturers have announced the discontinuation of some models (EOL), third-party suppliers still provide procurement and technical support services.

Typical application areas

As a universal servo drive solution, 603-AS-BV is widely used in:

Precision machine tools and automated processing equipment;

Packaging machinery and conveying systems;

Robot joint drive and servo pressure control;

Medical equipment and semiconductor manufacturing require strict positioning accuracy.

Its wide power range and flexible configuration enable it to adapt to diverse needs ranging from micro loads to medium to large industrial equipment.

Common fault diagnosis and solutions

In actual operation, it is necessary to pay attention to the following typical issues and corresponding strategies:

Overcurrent alarm: manifested as motor shaking or shutdown, which may be caused by motor short circuit, load overload, or power module damage. It is necessary to check the insulation of the motor winding, evaluate the load matching, and replace damaged modules if necessary.

Overvoltage/undervoltage protection: Overvoltage is mainly caused by brake resistor faults or power supply voltage fluctuations. It is necessary to detect the brake circuit and ensure stable power supply; Undervoltage may be caused by a power phase loss or a blown fuse, and the power supply line and fuse status need to be checked.

Overheating shutdown: often caused by poor heat dissipation or unreasonable parameter settings. Suggest cleaning the cooling air duct, checking the operation status of the fan, and optimizing parameters such as current limiting through software.

Position deviation and communication failure: Mechanical transmission clearance or encoder signal abnormalities need to be investigated for position deviation; In case of communication interruption, priority should be given to checking the integrity of cable contacts and interfaces.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-