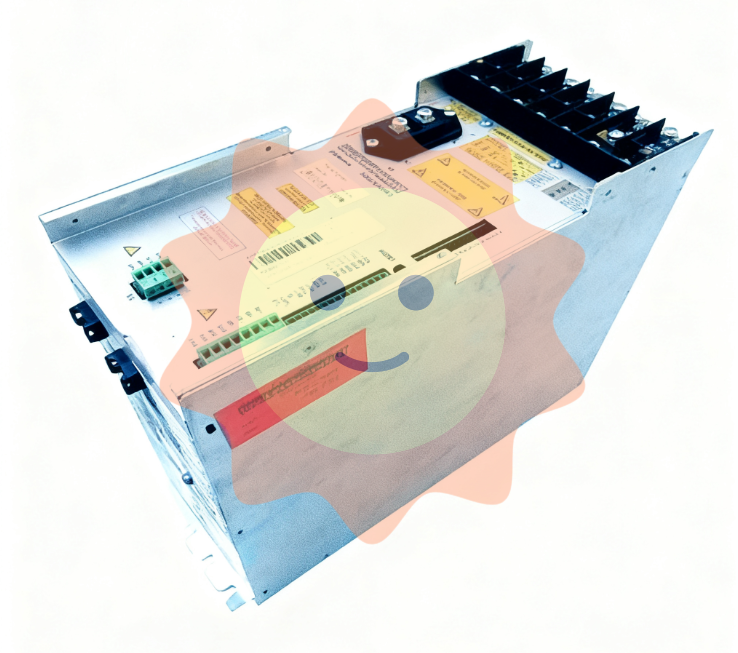

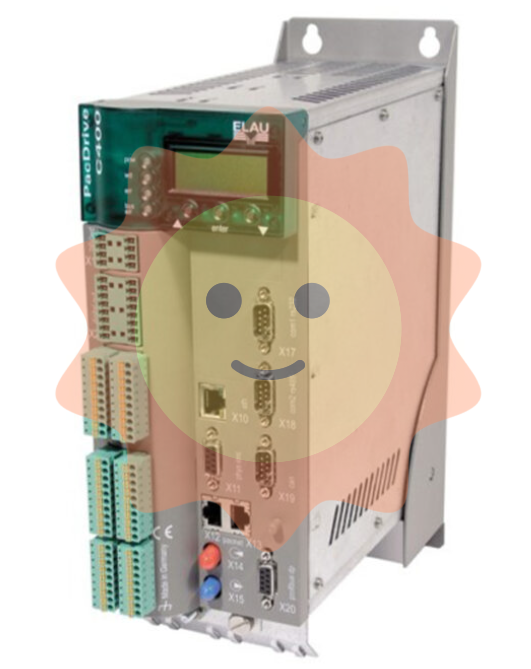

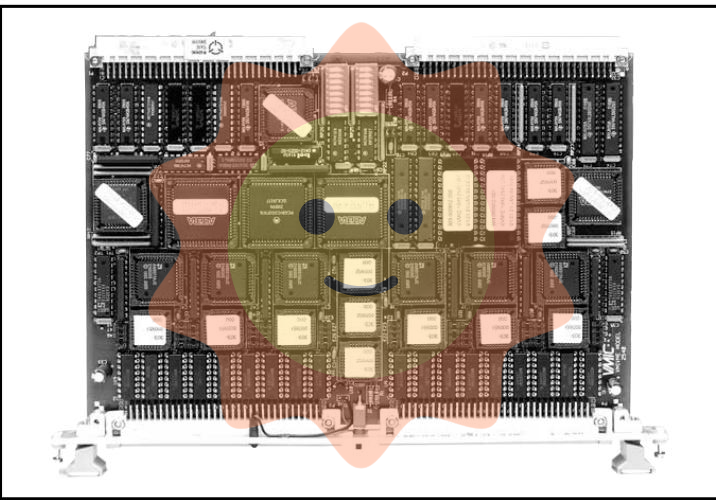

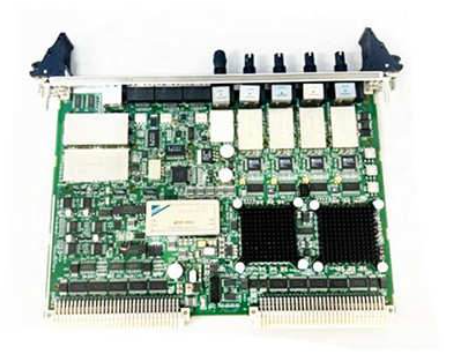

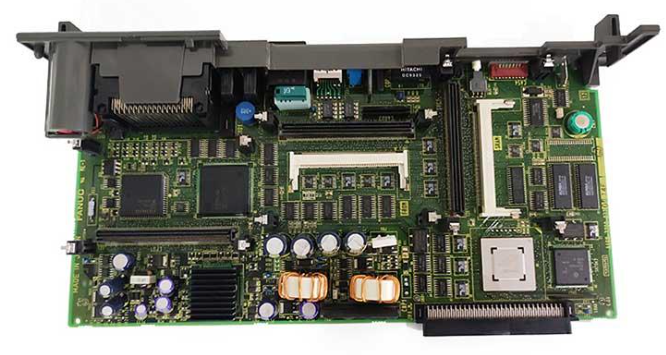

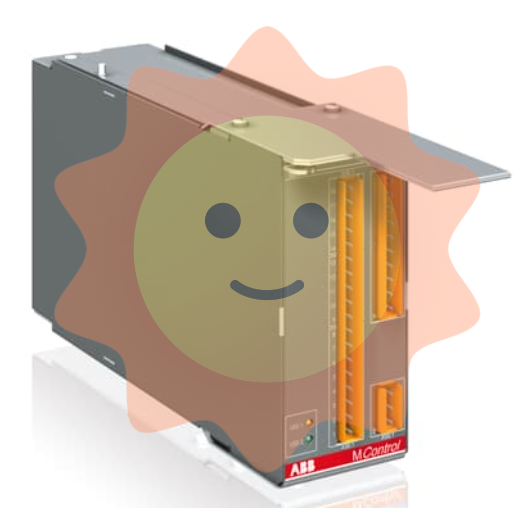

ABB 3HAC14550-2/09A Main servo drive unit

ABB 3HAC14550-2/09A Main servo drive unit

Overview

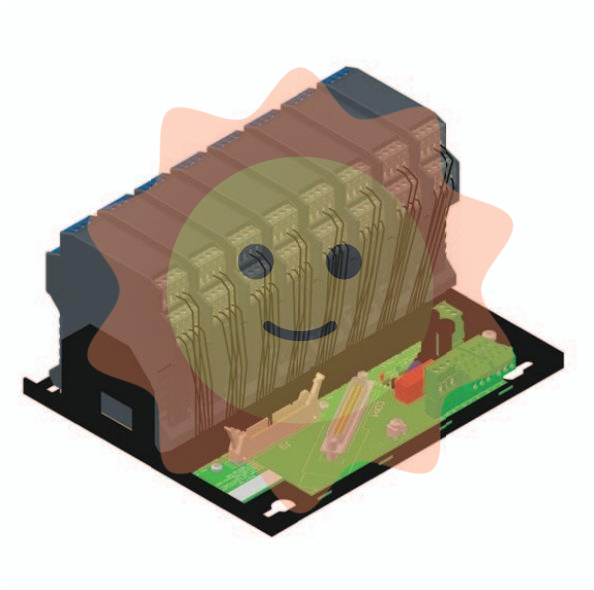

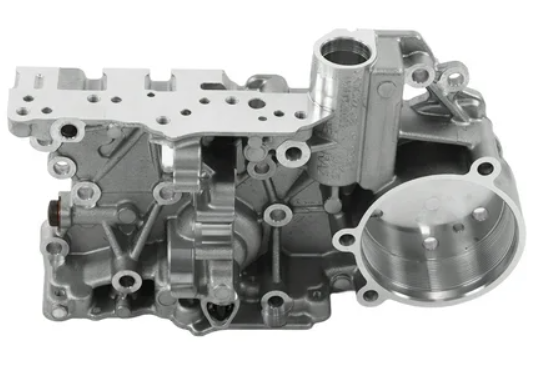

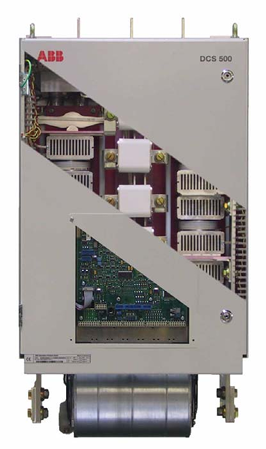

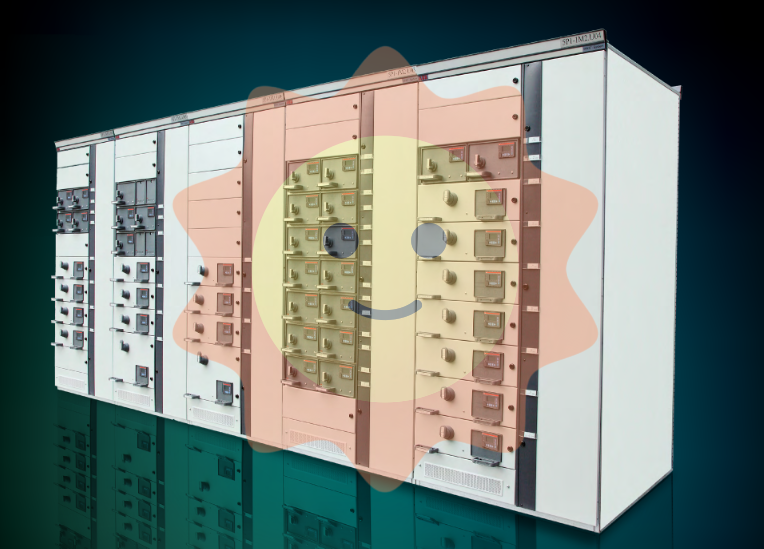

The ABB 3HAC14550 - 2/09A is a main servo drive unit, a crucial component in motion - control systems. Servo drive units are used to precisely control the speed, position, and torque of servo motors, enabling accurate and dynamic motion in various industrial applications.

Functionality and Features

Precise Motor Control

Speed Control: The primary function of this servo drive unit is to provide precise speed control of the connected servo motor. It can adjust the motor speed over a wide range, from very low speeds for precise positioning tasks to high - speed operations. The speed control accuracy is typically very high, often with an error margin of less than a fraction of a percent of the set speed. For example, in a CNC (Computer Numerical Control) machining application, it can control the spindle speed of a milling machine with high precision to achieve the desired surface finish of the machined part.

Position Control: It offers excellent position - control capabilities. The drive unit can accurately position the servo motor to a specific angular or linear position. The position - control accuracy can be in the range of micrometers or even smaller, depending on the motor and the feedback - sensor resolution. In a robotic - arm application, it enables the end - effector to reach the exact target position with high repeatability.

Torque Control: The 3HAC14550 - 2/09A can also control the torque output of the servo motor. This is crucial in applications where a specific force needs to be applied, such as in a material - handling robot gripping an object. The torque - control mode allows for a smooth and consistent force to be exerted, adapting to different load conditions.

Feedback and Closed - Loop Control

The servo drive unit utilizes feedback from sensors, usually encoders or resolvers attached to the servo motor. This feedback information is used to implement a closed - loop control system. The drive constantly compares the actual motor - speed, - position, or - torque with the commanded values and makes real - time adjustments to minimize errors. For example, if the motor's actual position deviates from the desired position due to external disturbances like load changes or friction, the drive unit will adjust the motor's current to correct the position.

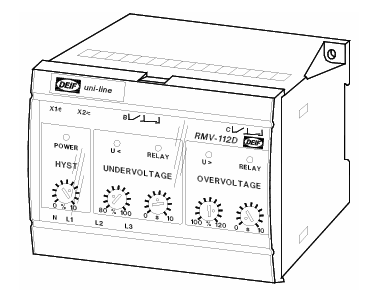

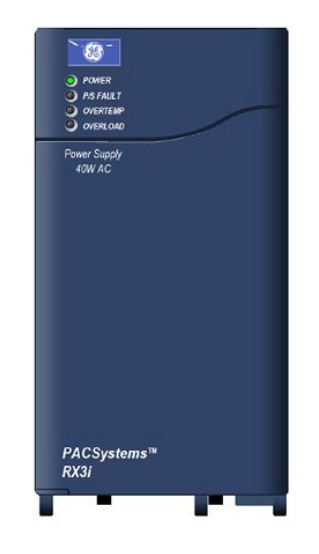

Over - Voltage, Over - Current, and Over - Temperature Protection

To safeguard the servo drive unit and the connected motor, it incorporates various protection mechanisms. It has over - voltage protection to prevent damage from power - supply surges. Over - current protection is in place to handle situations such as motor - stall or short - circuits. Additionally, over - temperature protection monitors the internal temperature of the drive unit and reduces the power or shuts down the system if the temperature exceeds a safe limit. These protection features enhance the reliability and lifespan of the equipment.

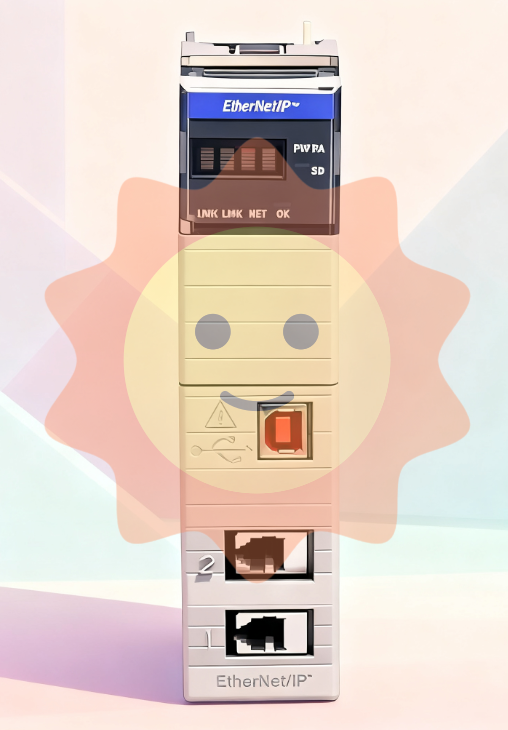

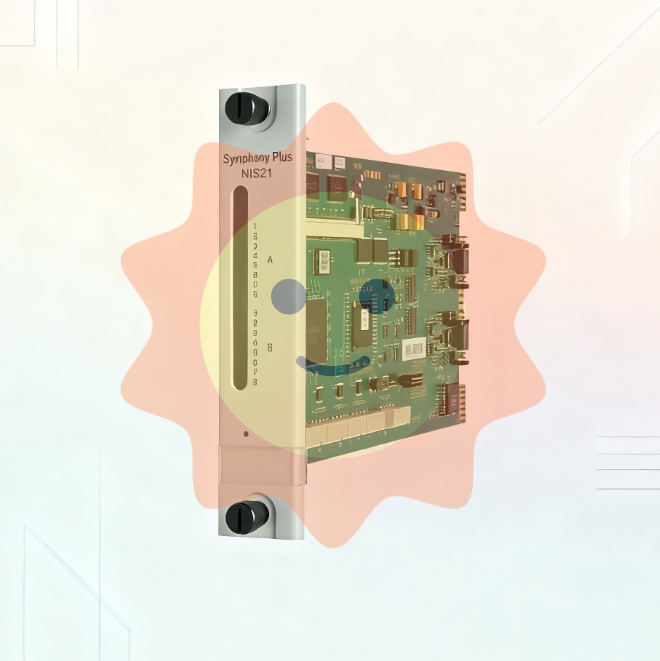

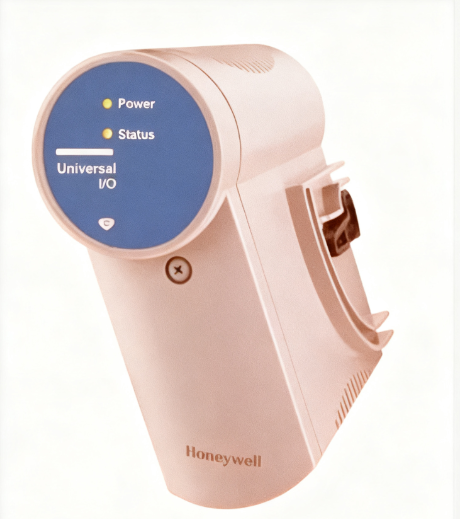

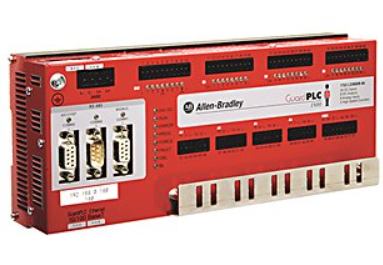

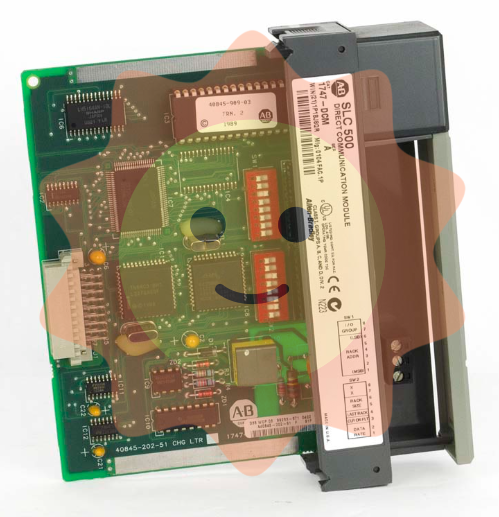

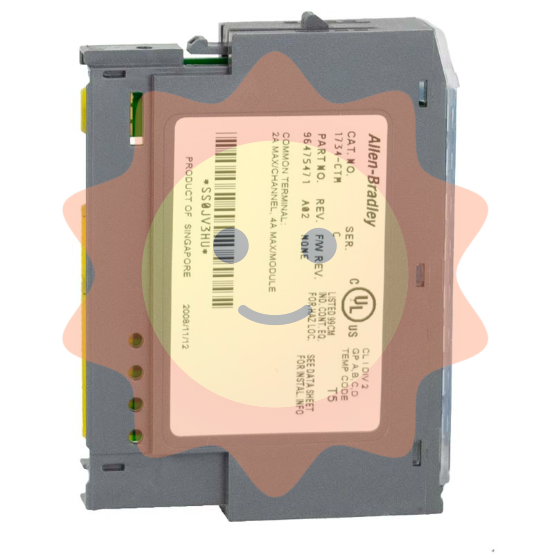

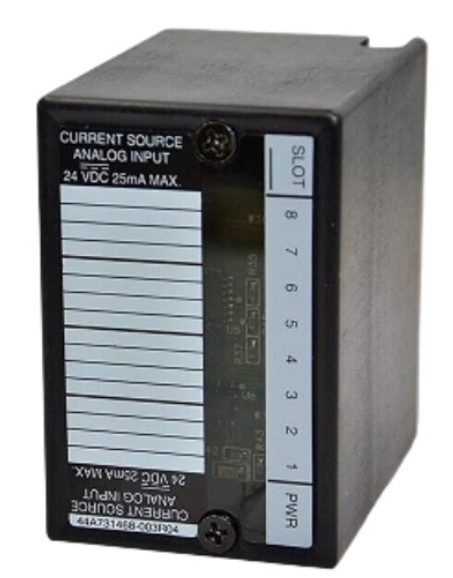

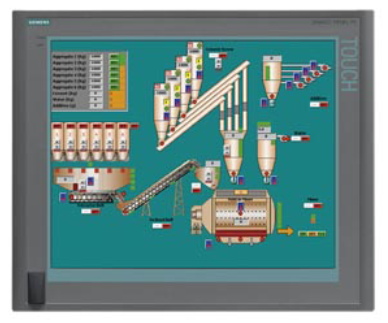

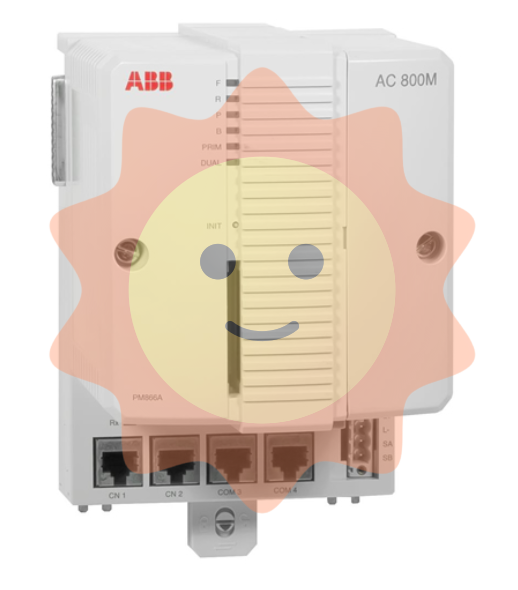

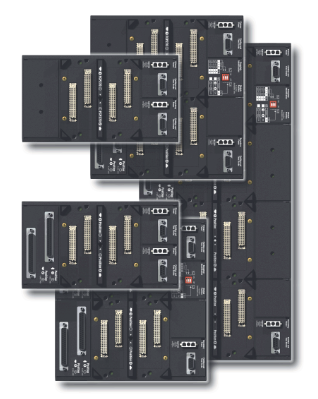

Communication and Networking Capabilities

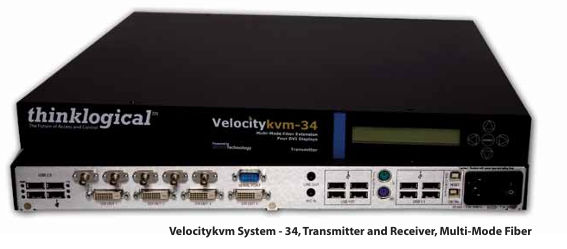

The 3HAC14550 - 2/09A is equipped with communication interfaces to interact with other components in the control system. It can communicate with Programmable Logic Controllers (PLCs), Human - Machine Interfaces (HMIs), and other servo drive units. The supported communication protocols may include CAN (Controller Area Network), Profibus, or Ethernet/IP. This enables coordinated motion - control in multi - axis systems and seamless integration into industrial - automation networks.

Technical Specifications

Power - Rating Specifications

The servo drive unit has a specific power - rating, which determines the maximum power it can deliver to the servo motor. The power - rating is usually given in kilowatts (kW) and can range from a few kW to larger values depending on the model and application requirements. The input - voltage range and frequency are also defined. For example, it might accept an AC input voltage in the range of 200 - 480V AC and a frequency of 50/60Hz.

Motor - Compatibility Specifications

It has details regarding the types of servo motors it can drive. This includes information about the motor - voltage, - current, and - torque - rating compatibilities. The maximum speed and position - resolution of the compatible motors are also specified. The drive unit may support different motor - feedback - sensor types and resolutions, ensuring flexibility in motor - selection for various applications.

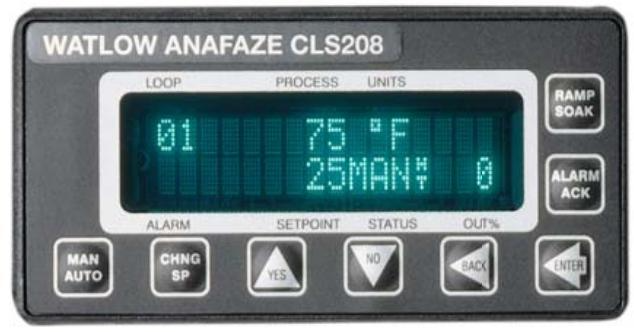

Control - Mode and - Parameter Specifications

The available control modes, such as speed - control, position - control, and torque - control, have their own sets of parameters. These include gain - settings for the control loops (proportional, integral, and derivative gains), acceleration and deceleration - rate settings, and filtering - parameters for the feedback - signals. The ability to adjust these parameters allows for fine - tuning the drive - unit performance to match the specific requirements of different applications.

Applications

Industrial Robotics

In industrial - robotics applications, the ABB 3HAC14550 - 2/09A servo drive unit is used to power and control the joints of robotic arms. It enables the precise and smooth movement of the robot, allowing it to perform tasks such as welding, painting, picking and placing, and assembly. The accurate position and speed - control capabilities are essential for the robot to operate with high efficiency and accuracy.

CNC Machining

In CNC machining operations, the servo drive unit controls the movement of the machine - tool axes. It can precisely position the cutting tool and control its speed during the machining process. This results in high - quality machined parts with tight tolerances. The drive unit's ability to handle different load - conditions and provide stable torque - control also helps in efficient material - removal operations.

Automated Material - Handling and Conveyor Systems

In material - handling and conveyor - belt systems, the servo drive unit can control the speed and position of motors used to move products or materials. It can provide precise control over the acceleration and deceleration of conveyor - belts, ensuring gentle handling of fragile products. In automated - storage - and - retrieval systems, it enables accurate positioning of the storage - retrieval - machines to access specific storage locations.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com