ABB DSBC172 57310001-KD is a high-performance bus repeater for industrial automation bus systems. Its core function is to extend the RS-485 bus communication distance, expand the number of device connections, and resist electromagnetic interference in industrial environments through electrical isolation technology. It is a key component to ensure the communication stability of large-scale distributed control systems. Its design is deeply adapted to ABB automation architecture and can seamlessly integrate into the bus network of PLC, DCS and other systems, providing reliable communication link support for complex industrial scenarios.

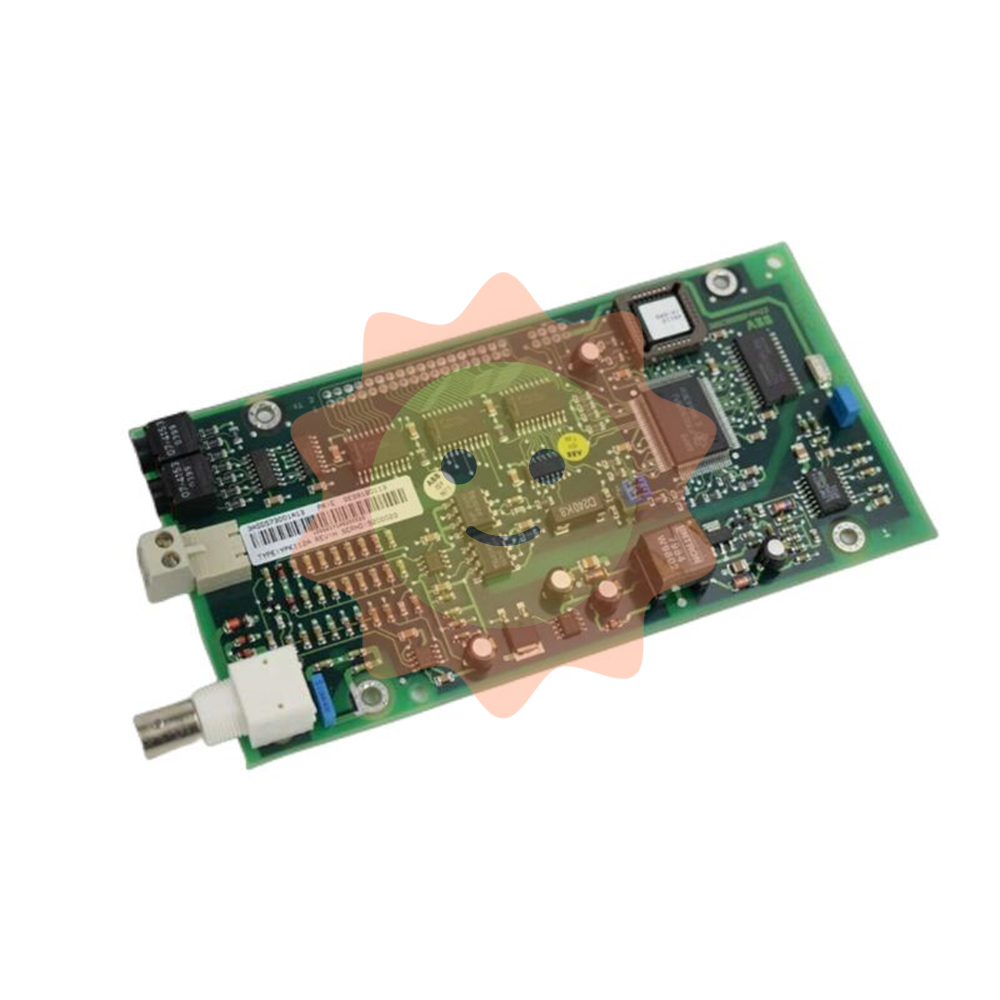

ABB DSBC172 57310001-KD BUS REPEATER

Product core positioning

ABB DSBC172 57310001-KD is a high-performance bus repeater for industrial automation bus systems. Its core function is to extend the RS-485 bus communication distance, expand the number of device connections, and resist electromagnetic interference in industrial environments through electrical isolation technology. It is a key component to ensure the communication stability of large-scale distributed control systems. Its design is deeply adapted to ABB automation architecture and can seamlessly integrate into the bus network of PLC, DCS and other systems, providing reliable communication link support for complex industrial scenarios.

Key technical parameters

Power supply specifications

Working voltage: 24V DC (typical value); Power consumption: ≤ 5W

Compatible with commonly used industrial DC power supplies and designed for low power consumption

Communication performance

Interface type: Dual RS-485 (independent input/output terminals); Communication protocol: compatible with industrial protocols such as Modbus and Profinet

Supports bidirectional relay of bus signals and adapts to mainstream control protocols

Transmission capability

Transmission distance: Single level relay extended to 1200 meters; Support cascading number: ≤ 8 levels; Device expansion quantity: up to 32 nodes/level

Significantly breaking through the inherent transmission limitations of the bus

Environmental adaptation

Working temperature: -20 ° C~+60 ° C; Storage temperature: -40 ° C~+70 ° C; Protection level: IP20

Adapt to industrial control rooms and general on-site installation environments

Physical specifications

Size: 90 × 120 × 30mm (estimated); Weight: ≤ 0.2kg; Installation method: DIN rail installation

Compact design, saving control cabinet space

Protection and Certification

Isolation strength: 2500V AC (photoelectric isolation); Surge protection: 600W; compliant with IEC 61000-4 standard

Effectively block common mode interference and enhance the system's anti-interference capability

Core functions and product features

1. Triple core communication enhancement capability

Distance extension: By using signal shaping and amplification technology, the transmission distance of a single segment RS-485 bus is extended from about 100 meters to 1200 meters, and with multi-level cascading, it can meet the cross regional communication needs of large factories.

Node expansion: A single level relay can support 32 terminal devices to access, solving the problem of device access restrictions caused by insufficient bus load capacity, and adapting to distributed sensor and actuator intensive scenarios.

Interference isolation: Adopting optoelectronic isolation and power isolation design to achieve electrical isolation of input/output terminals, block common mode voltage interference, and avoid signal distortion or module damage caused by equipment grounding differences.

2. High reliability industrial design

Wide temperature stable operation: operating temperature range of -20 ° C to 60 ° C, suitable for harsh environments in metallurgy, power and other industries, ensuring uninterrupted communication links under extreme temperatures.

Powerful protection mechanism: equipped with 600W surge protection and 15KV electrostatic protection functions, it can resist instantaneous voltage surges in industrial sites and reduce the risk of equipment damage.

Non disruptive operating characteristics: Supports hot swapping operations, and there is no need to shut down the bus system during module maintenance and replacement, ensuring production continuity.

3. System compatibility and usability

Full protocol adaptation: compatible with mainstream industrial communication protocols such as Modbus RTU and Profinet, can be connected to ABB AC 800M controllers, Freelance DCS and other systems, and also supports third-party RS-485 device networking.

Intelligent status monitoring: equipped with power and communication status indicator lights, providing real-time feedback on module operation status, making it easy to quickly locate communication fault points.

Quick deployment design: Standardized DIN rail installation structure, with screw free crimping design for wiring terminals to shorten installation and debugging time.

Typical application scenarios

Bus expansion in large factories: In automotive manufacturing and metallurgical plants, I/O modules and controllers scattered in different workshops are connected, and cross regional bus coverage is achieved through multi-level relays to solve the problem of long-distance communication attenuation.

Strong interference environment communication guarantee: In chemical and power equipment sites, electromagnetic interference generated by frequency converters, motors, and other equipment is blocked through electrical isolation functions to ensure stable transmission of sensor data.

Distributed control system networking: Cooperate with ABB PLC to build a distributed monitoring network, expand the number of on-site equipment connections, support multi-point data collection and command issuance in production lines, water treatment and other scenarios.

Upgrading and retrofitting of old systems: Without replacing the original terminal equipment, the communication performance of the system can be upgraded by extending the communication distance and improving anti-interference ability through repeaters.

Selection and Precautions

Link planning: Determine the relay level based on the communication distance (single level 1200 meters, maximum 8 levels) to avoid signal attenuation caused by over distance; Single level access devices should not exceed 32 to prevent bus overload.

Power matching: Ensure that the power supply is 24V DC and the ripple factor is ≤ 5% to avoid voltage instability affecting signal processing accuracy.

Wiring specification: Adopt Category 5e twisted pair shielded wire, separate and isolated input/output wiring, ground resistance ≤ 4 Ω, enhance anti-interference effect.

Compatibility verification: Before connecting to a third-party system, confirm the compatibility of the communication protocol and baud rate (adjustable from 300bps-115200bps). It is recommended to prioritize the use of ABB original supporting components.

Environmental protection: In humid and dusty environments, it is necessary to use an installation box with an IP54 or higher protection level to avoid module pin oxidation or short circuit.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-