ABB ARCOL 0339 is a customized frequency converter designed for high-frequency industrial drive scenarios, belonging to ABB's industrial automation drive product line. Its core positioning is the "power regulation center" for high-speed motors and precision loads. This device integrates high-frequency inverter, motor control, and status monitoring functions. It adopts a compact hardware architecture and customized parameter configuration design, which can achieve precise speed adjustment and power optimization of synchronous motors and high-speed drive equipment in harsh scenarios such as power generation, ships, and traction. At the same time, it supports seamless linkage with DCS systems and PLCs to meet the core requirements of industrial equipment for high-frequency drive and stable operation with high reliability.

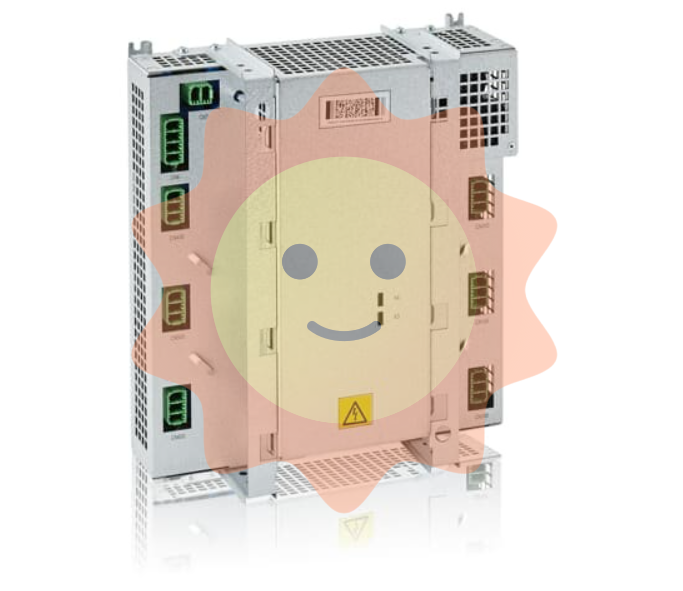

ABB ARCOL 0339 Industrial Frequency Converter

Product Overview

ABB ARCOL 0339 is a customized frequency converter designed for high-frequency industrial drive scenarios, belonging to ABB's industrial automation drive product line. Its core positioning is the "power regulation center" for high-speed motors and precision loads. This device integrates high-frequency inverter, motor control, and status monitoring functions. It adopts a compact hardware architecture and customized parameter configuration design, which can achieve precise speed adjustment and power optimization of synchronous motors and high-speed drive equipment in harsh scenarios such as power generation, ships, and traction. At the same time, it supports seamless linkage with DCS systems and PLCs to meet the core requirements of industrial equipment for high-frequency drive and stable operation with high reliability.

Specification parameters

Basic Information

Brand: ABB; Model: ARCOL 0339; Product type: High frequency industrial frequency converter; Origin: Imported from Europe and America; Customization: Support specific processing needs of customers

Suitable for synchronous motors and high-speed drive equipment, it is a core component of industrial drive and can customize parameters according to needs

Electrical specifications

Input voltage: AC 220V (compatible with 50/60Hz); Output frequency: 30kHz (high-frequency driver stage); Suitable motor power: ≤ 80MVA

Suitable for single-phase industrial power supply, 30kHz high-frequency output to meet the requirements of high-speed motor drive, supporting high-power unit applications

Performance specifications

Frequency regulation accuracy: ± 0.1Hz; speed control accuracy: ± 0.5% rated speed; Response time: ≤ 100ms

High frequency domain precise adjustment, fast response to load fluctuations, suitable for synchronous motor speed closed-loop control scenarios

Physical specifications

Dimensions (length x width x height): 450mm x 280mm x 180mm; Weight: 12kg; Installation method: wall mounted/cabinet mounted

Compact structure suitable for installation next to industrial control cabinets or equipment, moderate weight for easy fixation

Function configuration

Built in motor protection unit and high-frequency inverter module; Support dual mode control of speed/torque; Equipped with operation/fault indicator lights

Integrated core protection function, multi-mode control adapted to different load requirements, strong visibility of status

Performance characteristics

High frequency drive and precise adjustment

Adopting customized high-frequency inverter technology, the output frequency can reach 30kHz, far exceeding the low-frequency range of conventional frequency converters. It is particularly suitable for the high-speed driving needs of synchronous motors and can meet the power supply for high-speed operation of motors in scenarios such as wind power generation and ship propulsion. The frequency adjustment accuracy reaches ± 0.1Hz, and with a speed control accuracy of ± 0.5% of the rated speed, it can respond to load changes in real time (such as load fluctuations in ship propulsion systems), ensuring stable motor speed through closed-loop adjustment and avoiding equipment operation deviation caused by frequency drift.

Wide scene adaptation and customization flexibility

The adaptive motor power covers up to 80MVA, which can meet the driving needs of small high-speed equipment to large generator sets (such as diesel land-based power plants and gas turbines), and is compatible with the voltage regulation and speed control missions of synchronous motors. Support customized processing for specific customer needs, adjust output frequency range, protection parameters, and interface configuration according to application scenarios, such as optimizing response speed for traction systems and enhancing anti-interference capabilities for wind power generation, greatly improving adaptability to specific industrial scenarios.

High reliability and tolerance to harsh environments

The core components are selected based on industrial grade high-frequency tolerance, and the shell is made of high-strength flame-retardant material (in compliance with UL safety standards), which has good impact resistance and dust prevention performance. Through rigorous industrial environment adaptability testing, it can operate stably in high temperature, high humidity, and complex electromagnetic interference scenarios such as ship engine rooms and metallurgical workshops. Its robust design ensures continuous and reliable power output even under harsh conditions. Equipped with a built-in motor protection unit, it can monitor abnormal states such as overcurrent, overvoltage, and overload in real time, quickly cut off the output and give an alarm to avoid equipment damage.

System compatibility and convenient operation and maintenance

Supporting linkage with ABB DCS system and third-party PLC through standard industrial interfaces, it can be incorporated into the factory's centralized control system to achieve remote speed regulation and status monitoring, adapting to the automation integration needs of industries such as petrochemicals and steel metallurgy. Equipped with intuitive operation/fault indicator lights, which can quickly identify the working status of the equipment; Built in fault memory function, capable of storing recent fault codes, making it easy for operation and maintenance personnel to trace the cause. Daily maintenance does not require professional tools, regular cleaning of the cooling channels can ensure stable operation of the equipment and reduce the threshold for operation and maintenance.

Precautions

1. Selection and configuration precautions

Load matching: The compatibility needs to be confirmed based on the type of drive motor (synchronous motor only) and power (≤ 80MVA) to avoid overloading and damage to the frequency converter caused by excessive power operation; For different scenarios such as ship propulsion and wind power generation, customized parameters need to be communicated in advance to ensure that the output frequency and response speed meet the equipment requirements.

Power adaptation: The input power supply should be stable within the range of AC 220V ± 10%, and a voltage regulator should be installed when there is excessive fluctuation; The power circuit needs to be equipped with a separate circuit breaker (with a rated current of 1.2 times the input current of the frequency converter) to avoid voltage surges caused by sharing the circuit with high-power equipment.

System integration: When linking with the DCS system, it is necessary to confirm the compatibility of the communication interface protocol and prioritize the use of hard wired signals (4-20mA speed given) to ensure control reliability; High frequency output cables should use shielded special cables to reduce electromagnetic radiation interference.

2. Key points for installation and maintenance

Installation specifications: When wall mounted, it should be fixed on a solid wall with a load-bearing capacity of ≥ 20kg, and a distance of ≥ 30cm from surrounding objects should be reserved for heat dissipation; The installation inside the cabinet requires a forced cooling fan to ensure that the temperature inside the cabinet is ≤ 40 ℃. The input and output cables are laid separately with a spacing of ≥ 50cm, and the length of high-frequency output cables is ≤ 50 meters to avoid signal interference and power loss.

Debugging safety: Before the first power on, use a multimeter to check whether the input voltage meets the requirements of AC 220V and verify that the motor wiring phase sequence is correct. During debugging, run the program with no load first, start the automatic adjustment program through the "P1.1" parameter, and load the test after the display of "Complete"; It is necessary to adjust the control deviation band according to the load characteristics in parameter "P1.2" to ensure the stability of the adjustment.

Regular maintenance: Clean the cooling fan and filter every quarter, and check the tightness of the wiring terminals (tightening torque 2.5-3.0N · m); Check the output frequency accuracy and motor speed deviation every six months. If the deviation exceeds the standard, recalibrate it through the upper computer; Replace the cooling fan bearings annually to avoid triggering equipment overheating protection due to heat dissipation failure.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-