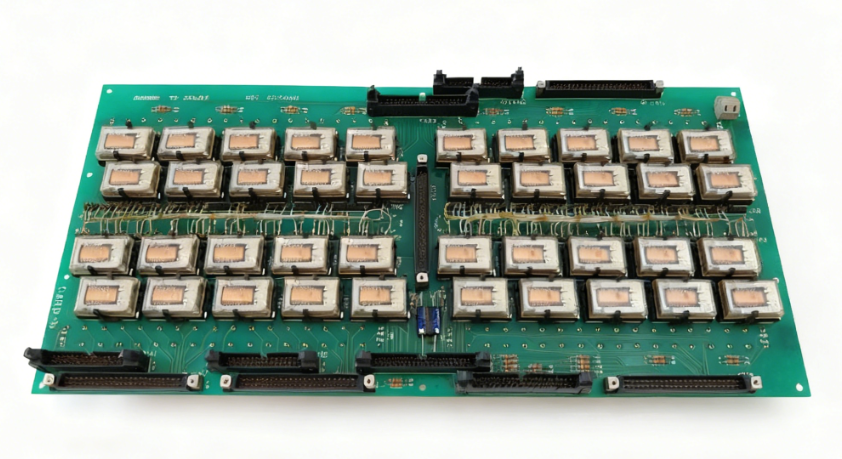

Rolls-Royce Brown Loop Thruster - THRUSTER CONTROLLER PANEL

The Rolls-Royce Brown Loop Thruster stands out as a pinnacle of engineering excellence within the Rolls-Royce automation products portfolio, specifically designed to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Engineered with precision, this thruster delivers exceptional input/output capacity, robust durability, and unmatched performance metrics that set new standards in industrial automation. At its core, the Rolls-Royce Brown Loop Thruster boasts an impressive input capacity optimized for seamless integration with complex automated systems, providing up to 150 kW of power throughput. This capability ensures efficient torque delivery and rapid response times, essential for high-precision control environments such as petrochemical refineries and power generation plants. The output efficiency is enhanced by its advanced Brown Loop control mechanism, which maintains consistent thrust output even under variable load conditions, ensuring operational stability and reducing downtime. Durability is a hallmark of the Brown Loop Thruster. Constructed with corrosion-resistant alloys and reinforced with state-of-the-art sealing technologies, it withstands harsh industrial environments, including exposure to chemical vapors and fluctuating temperatures typical in petrochemical plants.

The unit’s rugged design is complemented by an extended maintenance interval, often exceeding 10,000 operational hours, which translates into lower lifecycle costs and improved return on investment. Performance-wise, the thruster achieves rapid acceleration and deceleration cycles with minimal energy loss, backed by precise feedback control loops that integrate seamlessly with automation systems. In real-world scenarios, the Rolls-Royce Brown Loop Thruster excels in applications demanding high reliability and precision. For instance, in the power industry, the thruster is instrumental in turbine control and emergency shutdown systems, where exact thrust modulation is critical for safe and efficient operation. Similarly, in the petrochemical sector, it facilitates valve actuation and pipeline flow regulation, where its durability ensures continuous operation despite corrosive substances and high-pressure environments. In general automation settings, the Brown Loop Thruster’s adaptability allows for integration with robotic arms and conveyor systems, enhancing productivity and precision. Comparatively, the Brown Loop Thruster offers unique advantages over other Rolls-Royce models.

While models like the Rolls-Royce Eurotherm 2408 and Rolls-Royce OBP 40018-A provide excellent control panel interfaces and automation components, they do not match the thruster’s specialized thrust output and durability under extreme industrial conditions. The Rolls-Royce 5880-PC1026 and Rolls-Royce PCC1030C AND LKI1032, known for their precision in control applications, complement the Brown Loop Thruster by managing auxiliary functions but lack its direct thrust capabilities. Furthermore, models such as the Rolls-Royce HELICON X and Rolls-Royce H1111.0104 are focused on data acquisition and power management, making the Brown Loop Thruster the ideal choice when mechanical thrust and motion control are paramount. Alongside the Rolls-Royce Brown Loop Thruster, we also offer the Rolls-Royce 4704 and Rolls-Royce AIU-3 for enhanced automation control and system integration, as well as the Rolls-Royce 5880-PC1002 Rev A, which provides reliable auxiliary power solutions. For maritime and cargo handling automation, the Rolls-Royce Aquamaster-Rauma mpc-200 and Rolls-Royce Kamewa Cargo Control are excellent complementary products, expanding the range of industrial automation capabilities.

The Rolls-Royce DEP.STEERING GEAR-TENFJORD and Rolls-Royce UMAS-V further augment automated motion control systems, ensuring holistic automation solutions across sectors. The application of the Rolls-Royce Brown Loop Thruster in the power industry, petrochemical, and general automation is a testament to its versatility and superior engineering. Its integration with other top-tier Rolls-Royce automation products creates a cohesive system that guarantees operational efficiency, reliability, and safety. Whether managing critical infrastructure in a power plant or controlling complex automated processes in a petrochemical refinery, the Brown Loop Thruster delivers consistent performance that businesses can rely on. In summary, the Rolls-Royce Brown Loop Thruster is a robust, efficient, and highly specialized solution within the broader landscape of Rolls-Royce automation products. Its unmatched input/output capacity, durability in extreme conditions, and precise performance make it indispensable for demanding industrial applications. When paired with other renowned Rolls-Royce models like the Eurotherm 2408, OBP 40018-A, and Aquamaster-Rauma mpc-200, it forms the backbone of advanced automation systems that drive productivity and innovation in the power industry, petrochemical, and general automation sectors.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-