Rolls-Royce CANMAN SLIO-2 - [ NEW ] CONTROLLER NETWORK

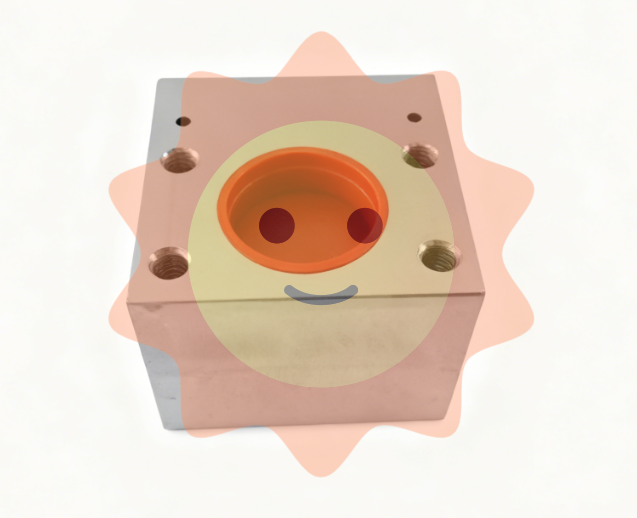

The Rolls-Royce CANMAN SLIO-2 stands as a pinnacle in advanced automation technology, specifically engineered to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. This robust controller offers a seamless integration of high input/output (I/O) capacities, exceptional durability, and superior performance metrics that set it apart within the Rolls-Royce automation products lineup. Technically, the CANMAN SLIO-2 features an extensive modular I/O system capable of handling up to 128 digital inputs and outputs, alongside 32 analog inputs and outputs. This wide range enables precise monitoring and control of complex industrial processes, ensuring real-time responsiveness and reliable data acquisition. Built for harsh industrial environments, the CANMAN SLIO-2 boasts an IP67-rated enclosure, guaranteeing resistance against dust, moisture, and temperature extremes, which is critical for continuous operation in challenging settings like petrochemical plants and power generation facilities. Its processing unit is powered by a state-of-the-art 32-bit microcontroller, delivering rapid cycle times under 1 millisecond, which ensures high-speed processing essential for mission-critical automation tasks. In terms of performance, the CANMAN SLIO-2 supports multi-protocol communication, including CANopen and Modbus TCP/IP, allowing seamless integration with existing plant networks and supervisory control systems. This flexibility simplifies the upgrade and expansion of legacy systems without compromising operational continuity.

The built-in diagnostics and fault-tolerant design further enhance system reliability, minimizing downtime and maintenance costs—a crucial factor in the high-stakes environments of power generation and petrochemical operations. When applied in real-world scenarios, the Rolls-Royce CANMAN SLIO-2 excels in managing complex automation workflows such as turbine control in power plants, real-time monitoring of chemical processing units, and automation of safety interlocks in refinery operations. Its ability to handle extensive I/O combined with rugged durability makes it an ideal choice for general automation applications where precision, reliability, and scalability are indispensable. Comparatively, the CANMAN SLIO-2 offers distinct advantages over other models within the Rolls-Royce automation portfolio. For instance, while the Rolls-Royce SLIO 01 provides a solid foundation for basic I/O control, the CANMAN SLIO-2 elevates performance with enhanced processing power and greater I/O capacity. Unlike the Rolls-Royce CanMan CCN01, which focuses primarily on network communication management, the SLIO-2 integrates both control and communication functionalities in a single, compact unit. Moreover, compared to the Rolls-Royce RRRLY8 and Rolls-Royce RRDIO15, which are designed for specific legacy automation tasks, the CANMAN SLIO-2 offers modernized interfaces and expanded scalability, making it future-proof for evolving industrial requirements.

Alongside the Rolls-Royce CANMAN SLIO-2, complementary models such as the Rolls-Royce 222-653 Plc2001b.PCB and the Rolls-Royce 5880-PC1020 Rev.B provide advanced programmable logic control capabilities, enhancing the overall automation ecosystem. The Rolls-Royce OBP 40018-A and the Rolls-Royce LIAAEN HELITRON DC0016A serve as reliable peripheral devices, ensuring smooth interoperability with the SLIO-2 controller. For applications demanding precise thruster control and marine automation, the Rolls-Royce Brown Loop Thruster and the Rolls-Royce Loop Thruster integrate efficiently with CANMAN SLIO-2’s control architecture. Additionally, the Rolls-Royce PCI-01 and Rolls-Royce MT-000551-A modules extend the controller’s functionality by delivering specialized process control and monitoring features. In summary, the Rolls-Royce CANMAN SLIO-2 is engineered to deliver unmatched reliability, scalability, and performance in demanding industrial environments. Its advanced I/O capacity, rugged design, and rapid processing power make it indispensable for power industry automation, petrochemical process control, and general automation applications.

When combined with related Rolls-Royce automation products such as the 25300016C, UN970, and the MEG-100-101-102, the CANMAN SLIO-2 forms the backbone of a comprehensive and highly efficient automation solution. For organizations seeking a robust, future-ready automation platform, the Rolls-Royce CANMAN SLIO-2 not only meets but exceeds expectations, reinforcing Rolls-Royce’s commitment to innovation and reliability in automation technology. Whether optimizing turbine operations, streamlining chemical processing, or advancing general automation workflows, the application of CANMAN SLIO-2 in the power industry, petrochemical, and general automation sectors remains unparalleled.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-