ABB CM15/000S0E0/STD is a universal process parameter indicator designed specifically for industrial environments. It is mainly used to receive analog signals (such as 4-20mA, 0-10V, etc.) from various sensors or transmitters, and display their corresponding process parameters in digital or analog pointer form. It also has a simple alarm prompt function. This product adopts standardized structural design, easy installation, strong anti-interference ability, and can adapt to the complex electromagnetic environment and harsh working conditions of industrial sites, providing clear and reliable information support for operators to grasp the process operation status in real time.

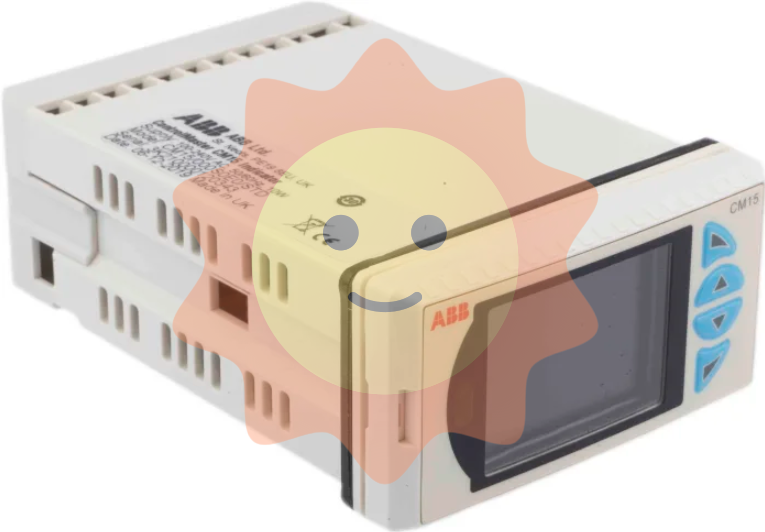

ABB CM15/000S0E0/STD Universal Process Indicator

Product Overview

ABB CM15/000S0E0/STD is a universal process parameter indicator designed specifically for industrial environments. It is mainly used to receive analog signals (such as 4-20mA, 0-10V, etc.) from various sensors or transmitters, and display their corresponding process parameters in digital or analog pointer form. It also has a simple alarm prompt function. This product adopts standardized structural design, easy installation, strong anti-interference ability, and can adapt to the complex electromagnetic environment and harsh working conditions of industrial sites, providing clear and reliable information support for operators to grasp the process operation status in real time.

Compared with traditional indicators, CM15/000S0E0/STD has been optimized in terms of display accuracy, signal adaptation range, and operational convenience. It not only meets the basic parameter display requirements, but also enables abnormal warning of key parameters through simple configuration, helping to achieve fine control of the production process.

Core functions

1. Multi signal compatibility and wide adaptability

This process indicator has strong signal adaptation capabilities and is compatible with various mainstream industrial analog input signals, including 4-20mA DC current signals, 0-10V DC voltage signals, etc. It can be directly connected to various field instruments such as pressure transmitters, temperature sensors, flow sensors, etc. Through internal parameter configuration, precise conversion and display of signals of different ranges can be achieved without the need for additional signal conversion modules, reducing system integration costs and complexity.

2. High definition display, intuitive and easy to read information

CM15/000S0E0/SDD adopts high brightness LED digital tubes or LCD displays (depending on the product configuration), with clear and eye-catching display. Even in strong light or dim industrial environments, operators can quickly read parameter values. The display screen supports flexible setting of unit symbols and decimal places, and can be personalized according to the characteristics of monitoring parameters (such as temperature ℃, pressure MPa, flow rate m ³/h, etc.) to ensure the professionalism and accuracy of displayed information.

3. Flexible alarm and risk early warning

To cope with production risks caused by abnormal process parameters, this indicator is equipped with high and low limit alarm functions. Operators can preset upper and lower limit alarm values for parameters according to production process requirements. When the monitored parameters exceed the preset range, the indicator will immediately sound an alarm through sound and light (such as flashing alarm lights or sounding buzzers) or relay output signals, reminding operators to take timely intervention measures to avoid production accidents or product quality problems caused by abnormal parameters.

4. Easy operation, convenient and efficient debugging

The product adopts a user-friendly interface design, equipped with a small number of functional buttons. Operators can complete parameter configuration work such as signal type selection, range calibration, alarm value setting, etc. through simple button combinations. At the same time, the indicator has a parameter memory function. After power failure and restart, the configured parameters will not be lost and do not need to be re debugged, effectively improving the maintenance efficiency and usability of the equipment.

5. Durable and adaptable to harsh environments

In response to the complex environment of industrial sites, CM15/000S0E0/SDD adopts high-strength shell material and tight sealing design, with good dust and moisture resistance performance, and a protection level of up to IP65 (specific to the product manual). Its internal circuit adopts anti electromagnetic interference design, which can effectively resist electromagnetic radiation interference in industrial sites, ensuring stable and accurate parameter display in scenarios such as high-power equipment operation and strong electrical signal fluctuations.

Key technical parameters

input signal

current signal

4-20mA DC (compatible with two-wire/four wire systems)

input signal

voltage signal

0-10V DC, 1-5V DC (optional)

Display performance

display mode

4-digit/5-digit LED digital display (red/green optional)

Display performance

display precision

± 0.1% FS (full-scale accuracy)

Display performance

response time

≤100ms

alarm function

Alarm Type

Upper limit alarm, lower limit alarm (independently adjustable)

alarm function

output method

Relay output (normally open/normally closed optional), capacity 2A/250V AC

Power Specifications

Working Voltage

AC 220V ± 10%, 50/60Hz; or DC 24V ± 15% (optional)

Environmental adaptation

Operating Temperature

-20℃~60℃

Environmental adaptation

relative humidity

10%~90% (no condensation)

Environmental adaptation

Protection level

IP65 (front panel)

Installation method

Installation Type

Panel installation (standard DIN size)

Applicable scenarios

With extensive signal adaptability and stable operational performance, ABB CM15/000S0E0/STD universal process indicators have been widely used in multiple industrial fields, mainly including:

1. Petrochemical industry: used to monitor parameters such as temperature and pressure of reaction vessels, flow rate and liquid level of media in pipelines, providing data support for the safety and controllability of chemical production processes.

2. Power industry: Suitable for monitoring parameters such as steam drum water level, steam pressure, and oil temperature in power plants and substations, to assist in the stable operation and fault warning of power equipment.

3. Water treatment industry: In waterworks and sewage treatment plants, it is used to display parameters such as water quality pH value, turbidity, liquid level, and pump outlet pressure to ensure the standard operation of water treatment processes.

4. Mechanical manufacturing industry: Monitor cutting temperature, hydraulic system pressure and other parameters during machine tool processing to provide real-time basis for precise control and maintenance of equipment.

5. Food and pharmaceutical industry: In food processing and drug production workshops, it is used to monitor key parameters such as sterilization temperature and fermentation tank pressure to ensure that the production process meets hygiene and quality standards.

6. Metallurgical industry: Suitable for parameter monitoring in high temperature and high dust environments such as furnace temperature and molten steel level during steelmaking and rolling processes, ensuring accurate data while withstanding harsh working conditions.

Key points for use

1. Installation specifications: The panel installation should be carried out in a ventilated, dry, and vibration free location. The installation aperture should match the product size to avoid display abnormalities caused by loose installation; The installation location should be far away from strong electromagnetic interference sources (such as high-power frequency converters and contactors), and shielding measures should be taken if necessary.

2. Wiring precautions: Before wiring, it is necessary to confirm that the power has been cut off, and strictly distinguish between power input, signal input, and alarm output interfaces to avoid equipment damage caused by incorrect connections; It is recommended to use shielded wires for signal lines and separate them from power lines to reduce interference.

3. Parameter calibration: Before the first use, the indicator should be calibrated according to the range of the connected sensor/transmitter to ensure that the displayed value is consistent with the actual process parameters; During the calibration process, a standard signal source is required to ensure calibration accuracy.

4. Alarm setting: According to the safety range of the production process, set the high and low limit alarm values reasonably to avoid risk omission caused by too loose alarm values or frequent alarms caused by too strict alarm values; If the alarm output is connected to an external actuator (such as an alarm light or solenoid valve), it is necessary to confirm that the load of the actuator matches that of the indicator.

5. Daily maintenance: Regularly clean the dust and stains on the indicator panel to avoid blocking the display; Check if the wiring terminals are loose and if the power supply voltage is stable; If not used for a long time, regular power on testing is required to ensure the normal performance of the equipment.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-