The ABB COM0034 control module is a modular product designed specifically for complex control requirements in industrial sites. It adopts a standardized hardware architecture and programmable control core, which can achieve real-time acquisition, processing, and precise control of multiple input and output signals. This module adheres to ABB's consistent industrial design philosophy and has the characteristics of anti electromagnetic interference, high and low temperature resistance, and adaptability to harsh environments. It can be seamlessly integrated into mainstream PLC systems such as ABB AC500 and AC800M, and can also work together with third-party automation equipment through standardized communication protocols, providing highly flexible solutions for the construction of industrial control systems.

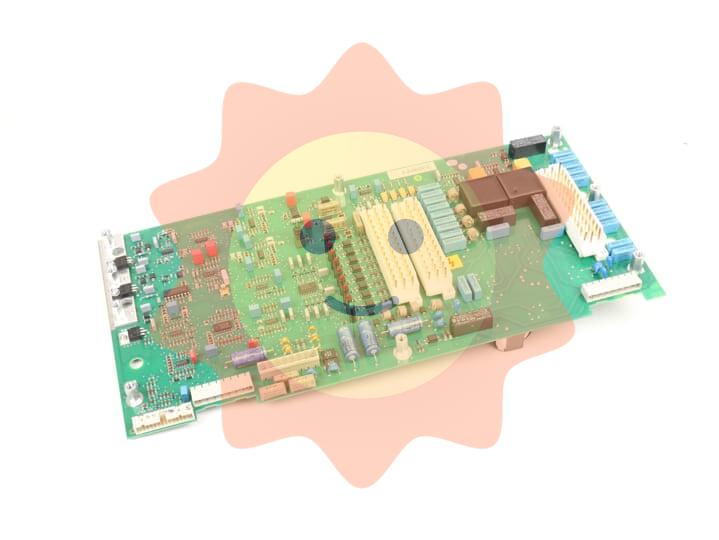

ABB COM0034 control module

Product Overview

The ABB COM0034 control module is a modular product designed specifically for complex control requirements in industrial sites. It adopts a standardized hardware architecture and programmable control core, which can achieve real-time acquisition, processing, and precise control of multiple input and output signals. This module adheres to ABB's consistent industrial design philosophy and has the characteristics of anti electromagnetic interference, high and low temperature resistance, and adaptability to harsh environments. It can be seamlessly integrated into mainstream PLC systems such as ABB AC500 and AC800M, and can also work together with third-party automation equipment through standardized communication protocols, providing highly flexible solutions for the construction of industrial control systems.

Compared with traditional control modules, COM0034 has significantly improved computing speed, signal processing accuracy, and scalability. Its modular design allows users to add or remove functional modules according to actual needs, reducing system construction costs while also reserving sufficient space for later equipment upgrades.

Core functions

The functional design of ABB COM0034 control module revolves around the core control requirements of industrial sites, covering multiple dimensions such as signal processing, logic control, communication linkage, fault diagnosis, etc., as follows:

1. High precision signal acquisition and processing

The module supports multiple analog inputs (such as 4-20mA current signals, 0-10V voltage signals) and digital inputs (switch signals), with 16 bit AD conversion accuracy. It can accurately collect key parameters such as temperature, pressure, flow rate, and liquid level in industrial sites, with acquisition errors controlled within ± 0.1%. In response to complex interference signals on site, the module is equipped with signal filtering circuits and isolation protection units, which can effectively suppress electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring the stability and authenticity of the collected signals.

2. Flexible programmable logic control

The module is equipped with a high-performance 32-bit microprocessor and supports multiple programming languages according to the IEC 61131-3 standard (such as ladder diagram LD, function block diagram FBD, structured text ST, etc.). Users can develop control logic through programming software such as ABB Automation Builder. Its operation cycle can reach as short as 1ms, which can quickly respond to control requirements, achieve precise start stop, speed adjustment, stroke control and other operations of actuators such as motors, valves, pumps, etc., and meet the real-time control requirements in continuous production processes.

3. Diversified communication and system linkage

COM0034 has built-in rich communication interfaces, including Ethernet (Ethernet/IP, PROFINET), serial communication (RS485, RS232), and fieldbus (PROFIBUS DP, Modbus RTU/TCP), etc., which can realize data interaction with PLC master station, human-machine interface (HMI), SCADA system and other intelligent devices. Through standardized communication protocols, the module can upload the collected on-site data to the monitoring center and receive control instructions issued by the upper level system, achieving collaborative linkage of the entire industrial control system.

4. Comprehensive fault diagnosis and protection

To ensure the continuity of industrial production, the module has complete fault diagnosis and self-protection functions. It can monitor the working status of the module itself in real time (such as power supply voltage, CPU operating temperature) and the operating parameters of connected devices. When there are signal abnormalities, communication interruptions, overloads, short circuits and other faults, it will immediately trigger alarm signals (such as indicator lights flashing, relay outputs) and upload the fault information to the upper system. At the same time, the module is equipped with built-in overvoltage and overcurrent protection circuits, which can effectively prevent the expansion of faults from causing damage to the module and related equipment.

5. Modular expansion and redundancy design

Based on ABB's standardized module architecture, COM0034 supports seamless integration with digital I/O modules, analog output modules, and special function modules (such as counting modules and positioning modules). Users can flexibly configure the number of modules according to the control scale. For scenarios that require high reliability, the module supports redundant configuration. When the main module fails, the backup module can switch within milliseconds to ensure uninterrupted control process.

Key technical parameters

Power parameters

Rated power supply voltage

24V DC(±10%)

Power consumption

≤ 5W during normal operation, peak value ≤ 8W

power protection

Overvoltage, overcurrent, and reverse connection protection

input parameters

Analog input

8 channels, supporting 4-20mA/0-10V, 16 bit accuracy

Digital input

16 channels, NPN/PNP optional, response time ≤ 10 μ s

Input isolation

Isolation between analog and digital signals, isolation voltage ≥ 500V AC

Filtering function

Programmable digital filtering, adjustable filtering time from 0.1ms to 100ms

output parameters

Analog output

4 channels, supporting 4-20mA/0-10V, 14 bit accuracy

digital output

8 channels, relay output (2A/250V AC) or transistor output (0.5A/24V DC)

Output response time

Analog quantity ≤ 1ms, digital quantity ≤ 10 μ s

communication parameters

Ethernet interface

1 RJ45, supports 10/100Mbps adaptive, compatible with PROFINET, Ethernet/IP

serial interface

2-channel RS485, 1-channel RS232, supports Modbus RTU, PROFIBUS DP

Communication speed

Serial communication up to 115200bps, Ethernet up to 100Mbps

environmental parameters

Operating Temperature

-20℃~60℃

relative humidity

5%~95% (no condensation)

Protection level

IP20 (module itself), with control cabinet up to IP54

Other parameters

processor

32-bit ARM Cortex-M4, clock speed 168MHz

storage capacity

Flash:1MB,RAM:128KB

Applicable scenarios

With its stable performance, flexible configuration, and strong compatibility, ABB COM0034 control module has been widely used in multiple industrial fields, with core application scenarios including:

1. Power industry: Electrical equipment monitoring and control

In scenarios such as substations and power plants, COM0034 can be used to monitor key parameters such as transformer temperature, bus voltage, and current. Through logical control, it can achieve automatic opening and closing of circuit breakers, switching of reactive power compensation devices, and start stop control of auxiliary equipment such as fans and pumps. Its ability to resist electromagnetic interference can adapt to the complex electromagnetic environment of the power system and ensure the stable operation of equipment.

2. Manufacturing industry: Automated control of production lines

In production lines such as automobile manufacturing, electronic processing, and food packaging, modules can serve as distributed control units to collect signals such as material location and equipment operation status on the production line. Through programming logic, they can achieve control functions such as process linkage, quality inspection, and fault shutdown. Its modular expansion capability can adapt to production lines of different scales, improving production efficiency and product qualification rate.

3. Chemical industry: precise control of process parameters

The precise control of parameters such as temperature, pressure, liquid level, and flow rate in the chemical production process is directly related to production safety and product quality. COM0034 can collect these parameters in real-time and accurately control equipment such as reaction vessels, heat exchangers, pumps, and valves through PID adjustment algorithms. At the same time, its fault diagnosis function can promptly detect abnormal situations such as leaks and overheating, triggering safety protection mechanisms.

4. Water treatment industry: Process automation management

In waterworks and sewage treatment plants, modules can be used to monitor water quality indicators (such as pH value, turbidity), water tank levels, and other parameters, control the operation of dosing pumps, aeration equipment, and sludge treatment equipment, and achieve automated process management of water treatment processes. Its moisture resistance and corrosion resistance can adapt to the environmental requirements of water treatment sites.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-