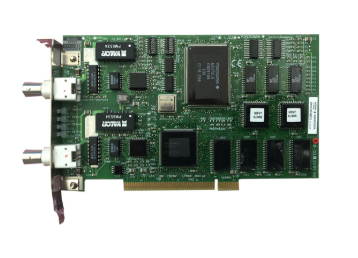

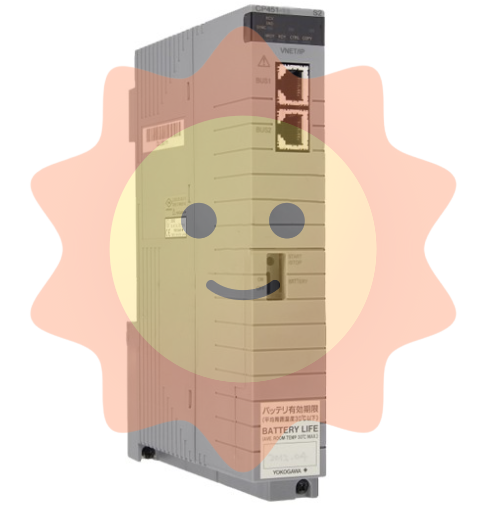

YOKOGAWA CP451-50 is a core control component developed by Yokogawa Electric for the industrial automation field. It belongs to the CENTUM CS series distributed control system (DCS) and serves as the "computing and command center" of the entire control system. This module undertakes key tasks such as control algorithm execution, on-site signal processing, cross device data interaction, and system logic control. With industrial grade stable design and flexible expansion capabilities, it widely adapts to the control needs of various complex industrial scenarios, providing reliable core computing support for process control, batch control, and safety instrumented systems. In its model code, "5" represents the standard type without explosion-proof protection design, and "0" represents the basic functional version, which can meet the mainstream control requirements in conventional industrial environments.

YOKOGAWA CP451-50 processor module

Product Overview

YOKOGAWA CP451-50 is a core control component developed by Yokogawa Electric for the industrial automation field. It belongs to the CENTUM CS series distributed control system (DCS) and serves as the "computing and command center" of the entire control system. This module undertakes key tasks such as control algorithm execution, on-site signal processing, cross device data interaction, and system logic control. With industrial grade stable design and flexible expansion capabilities, it widely adapts to the control needs of various complex industrial scenarios, providing reliable core computing support for process control, batch control, and safety instrumented systems. In its model code, "5" represents the standard type without explosion-proof protection design, and "0" represents the basic functional version, which can meet the mainstream control requirements in conventional industrial environments.

Core technical parameters

2.1 Processor and Memory Configuration

The module adopts a high-performance 32-bit RISC processor with a computing frequency of up to 10MHz, which has efficient data processing capabilities and can quickly respond to multi-channel input signals and execute complex control logic. In terms of memory configuration, it is equipped with 64KB random access memory (RAM) for temporarily storing real-time computational data, program running cache, and dynamic signals collected on site; Equipped with 32KB erasable programmable read-only memory (EPROM), it is used to solidify the system boot program, basic control algorithms, and core configuration parameters, ensuring that the module can quickly start and run stably after power on, and that critical program data is not lost after power off.

2.2 Electrical and Environmental Parameters

-Power specification: Using industrial standard 24VDC DC power supply, the power input range has a certain degree of fault tolerance and can adapt to fluctuating voltages of 21V-27VDC, ensuring normal operation even when the industrial power grid voltage is unstable; The power consumption is low, with a typical power consumption of ≤ 15W during operation and ≤ 3W during standby, combining energy efficiency and stability.

-Working environment: The working temperature range is -20 ° C to 60 ° C, which can adapt to multiple temperature scenarios such as high-temperature industrial workshops and low-temperature storage control; The relative humidity tolerance range is 10% -90% (no condensation), which can cope with humid or dry industrial environments; The protection level reaches IP20 or above, which can effectively prevent foreign objects such as dust and debris from entering the module and protect the core circuit from damage.

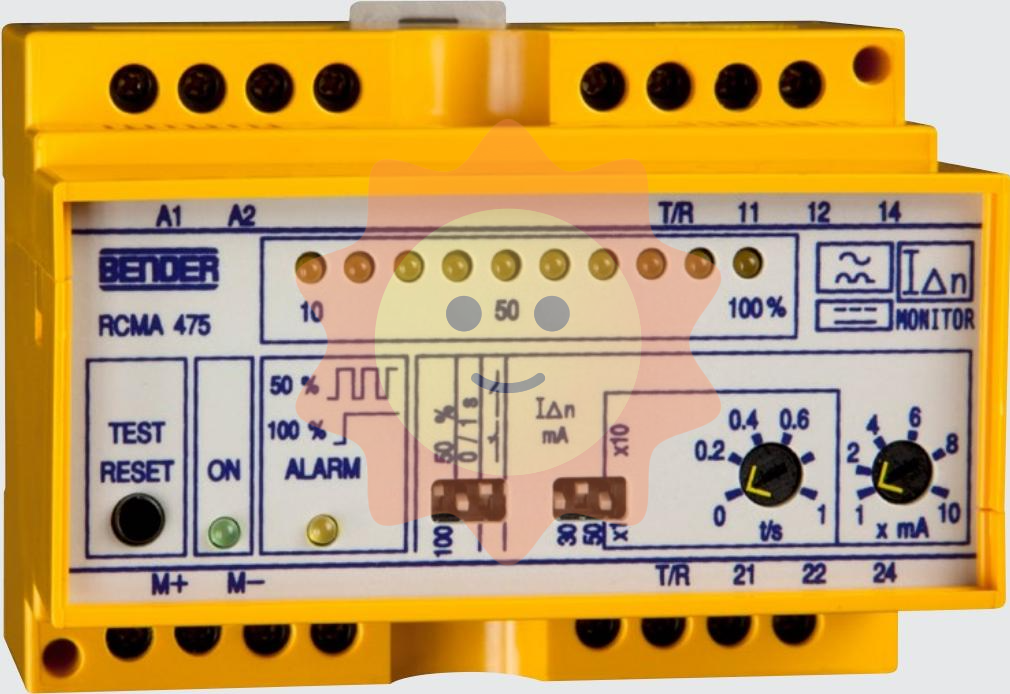

-Physical characteristics: The external dimensions are 48mm x 96mm x 140mm (length x width x height), with a compact structure that saves cabinet installation space; Weighing approximately 1.4kg, convenient for transportation and installation; Adopting the standard DIN rail installation method, it can be directly mounted on industrial standard rails, with fixed buckles to ensure a firm installation and better anti vibration performance.

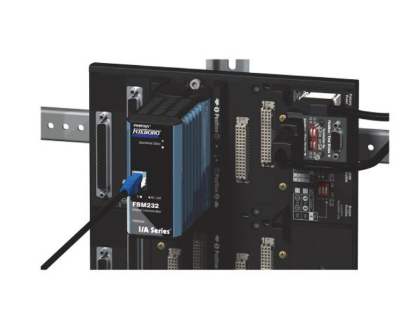

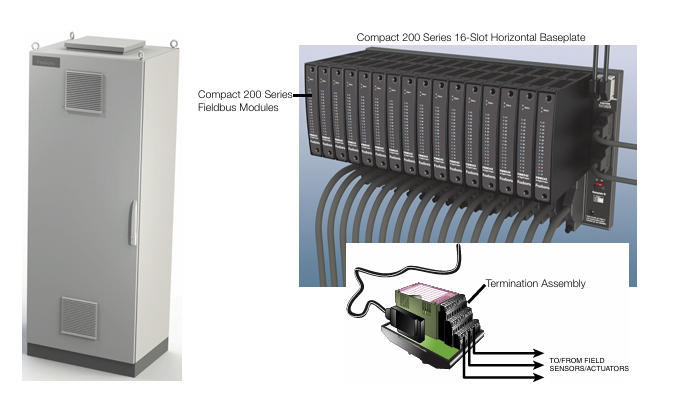

2.3 Input/Output and Scalability

The module supports flexible I/O expansion configuration, and can connect various analog and digital I/O modules through dedicated expansion interfaces. It can expand up to 256 input points and 256 output points, and can accurately match configuration requirements according to the on-site control scale. The input signal supports 4-20mA analog signal, 0-10V voltage signal, and switch signal. The output signal can adapt to 4-20mA analog control signal and relay switch signal, compatible with the signal specifications of mainstream industrial sensors and actuators, and can be directly connected without the need for additional signal conversion modules.

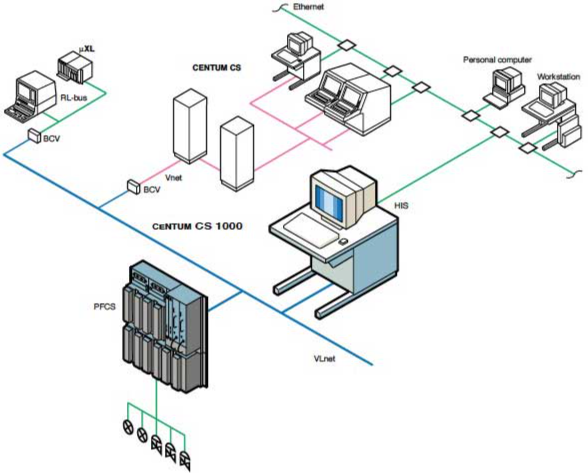

2.4 Communication Interface and Protocol Support

The module is equipped with multiple types of communication interfaces and has strong cross device interconnection capabilities: on the one hand, it supports mainstream serial communication protocols such as Modbus, ASCII, RTU, etc., and can achieve point-to-point data interaction with underlying devices such as field instruments, frequency converters, encoders, etc; On the other hand, it is compatible with industrial Ethernet protocols such as Ethernet/IP, Profinet, EtherCAT, etc., and can be connected to factory level industrial Ethernet to achieve high-speed data sharing with upper monitoring systems, engineer stations, and other DCS nodes. The communication speed can reach up to 100Mbps, ensuring real-time transmission of massive control data. The interface forms include RJ45 Ethernet port and RS485/RS232 serial interface, meeting the requirements of different communication distances and speeds.

Core functional characteristics

3.1 High performance real-time control

Relying on the efficient computing capability of 32-bit RISC processors, the module can simultaneously process multiple on-site signals, supporting various classic process control algorithms such as proportional integral derivative (PID) control, cascade control, feedforward control, as well as custom logic control algorithms. The control cycle can be as low as milliseconds, and it can accurately respond to on-site parameter fluctuations to ensure control accuracy. For complex control scenarios such as multivariable coupling and large lag, the module has strong anti-interference ability and parameter self-tuning potential. It can optimize control strategies through software configuration to improve control stability.

3.2 High reliability industrial grade design

The module adopts full industrial grade component selection and reinforcement design, with excellent anti vibration and anti impact performance: the vibration tolerance level is 10-57Hz, the amplitude is 0.075mm, and the impact tolerance level is 15g (11ms), which can adapt to the vibration generated by the operation of mechanical equipment in industrial sites and the impact during transportation. At the same time, the module integrates overvoltage, overcurrent, and short-circuit protection circuits internally. When the power supply voltage is abnormal or the output terminal is short circuited, the relevant circuits can be quickly cut off to avoid module damage; The circuit design adopts isolation technology to effectively suppress electromagnetic interference (EMI) in industrial sites, ensuring the accuracy of signal transmission and computation.

3.3 Flexible Programming and Configuration

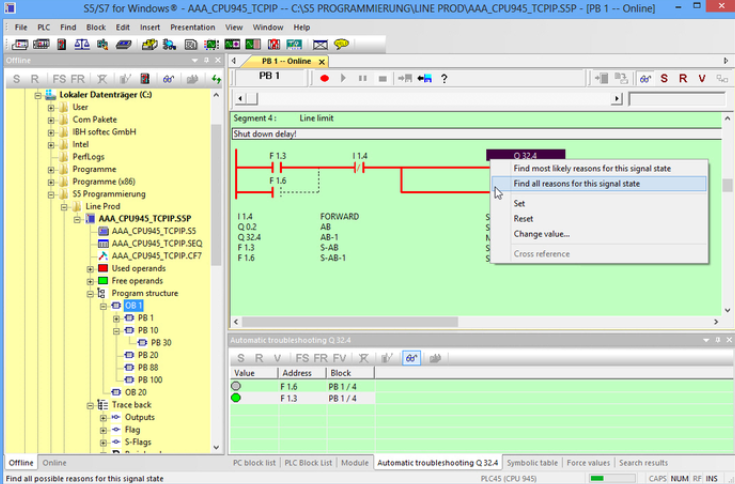

The module fully supports multiple programming languages specified in the IEC 61131-3 standard, including Instruction List (IL), Ladder Diagram (LD), Function Chart (FC), Structured Text (ST), and Sequential Function Chart (SFC), to meet the programming habits and control scenario requirements of different users. Among them, ladder diagrams are suitable for logic control scenarios, structured text is suitable for complex algorithm programming, and functional charts facilitate the implementation of sequential control processes. Users can write, debug, upload, and download programs through Yokogawa's dedicated programming software. The software supports online monitoring of program running status, parameter modification, and fault diagnosis, improving development and maintenance efficiency.

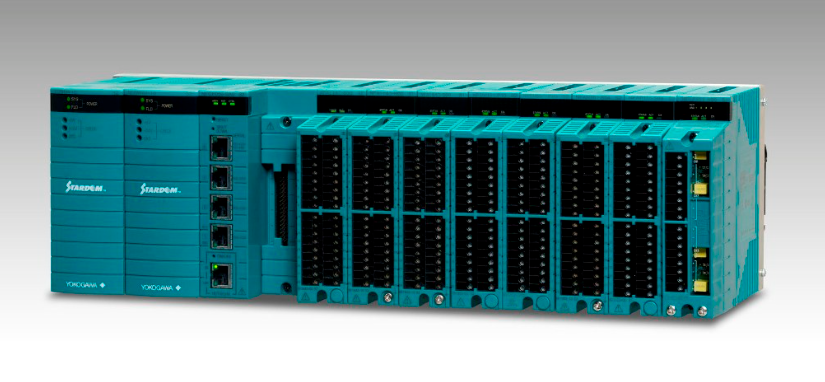

3.4 Comprehensive System Compatibility and Redundancy Capability

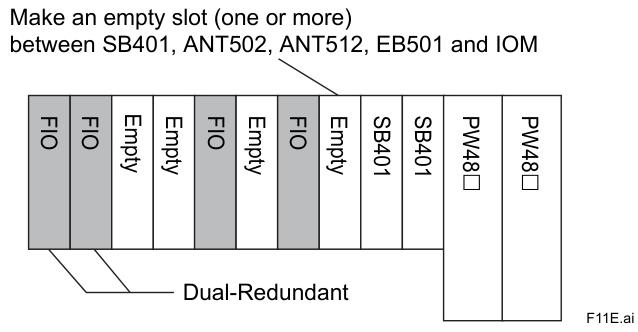

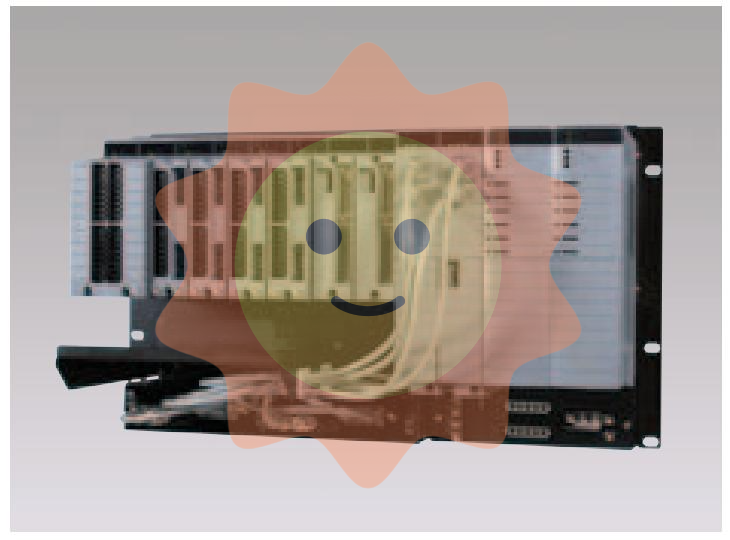

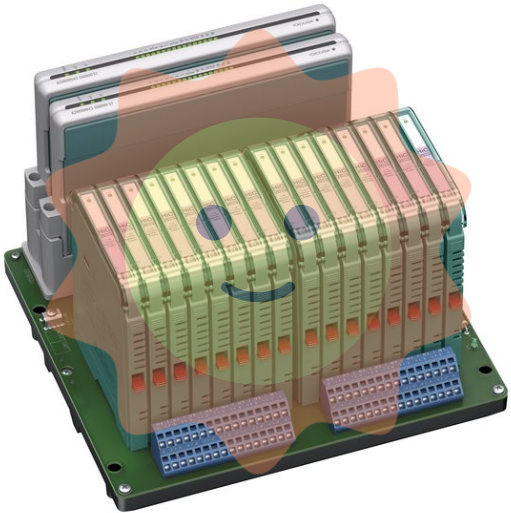

As the core component of the CENTUM CS series, CP451-50 is seamlessly compatible with various I/O modules, communication modules, power modules, etc. within the series, and supports system level redundancy configurations (such as dual power redundancy and dual processor redundancy). When the main processor module fails, the redundant module can quickly switch and take over the work, with a short switching time, ensuring that the control system is not interrupted and improving the availability of the entire system. At the same time, the module supports interconnection with other series of DCS or third-party control systems in Yokogawa, achieving cross system data sharing through standard industrial protocols, and adapting to the system integration requirements in the digital transformation of factories.

Installation and commissioning precautions

4.1 Preparation before installation

Before installation, carefully read the product user manual to confirm that the installation environment meets the module requirements: stay away from high temperature heat sources, flammable and explosive gases, and strong electromagnetic interference sources (such as high-voltage cables and frequency converters); Adequate heat dissipation space should be reserved at the installation location, and the distance between the module and other equipment or cabinet walls should not be less than 50mm to avoid overheating and damage to the module due to poor heat dissipation; During transportation and storage, the ambient temperature should be controlled between -30 ° C and 80 ° C, the relative humidity should not exceed 90%, and there should be no corrosive gases, strong vibrations, or collisions. The original packaging box should be used for fixation during transportation.

4.2 Installation and operation specifications

-Installation method: DIN rail installation is adopted. First, fix the rail firmly, and then smoothly clip the module into the rail to ensure that the module buckle is fully engaged with the rail and avoid loosening; If multiple modules need to be installed side by side, the spacing between modules should be kept at least 10mm to facilitate heat dissipation and wiring operations.

-Wiring specifications: Before wiring, all relevant power sources must be cut off to avoid module short circuits or electric shock caused by live wiring; The power wiring should strictly distinguish between positive and negative poles, and reverse connection is strictly prohibited. It is recommended to use shielded cables with 15-22AWG specifications to reduce signal interference; Signal cables and power cables should be wired separately and should not be laid in the same pipe or bundled together. If cross wiring is required, a vertical cross method should be used to reduce electromagnetic coupling interference; After the wiring is completed, it is necessary to check whether all wiring terminals are tightened to avoid loose connections and poor contact, and install terminal covers to prevent electric shock.

-Grounding requirements: The module needs to be grounded separately, and the grounding terminal should be connected to a dedicated industrial grounding system with a grounding resistance of ≤ 4 Ω. It is strictly prohibited to share the grounding with heavy electrical equipment to avoid interference from the grounding circuit and affect the normal operation of the module.

4.3 Debugging process and key points

Before debugging, it is necessary to check the power supply, wiring, and installation status again. After confirming that there are no errors, connect the power supply:

1. Power on self-test: After the module is powered on, the self-test status is determined by the panel indicator lights. A green light that stays on indicates a normal self-test, while a flashing or constant red light indicates a fault. It is necessary to refer to the manual to troubleshoot power supply, wiring, or module issues.

2. Parameter configuration: Connect modules through programming software, download preset control programs and parameters, including I/O channel configuration, control algorithm parameters, communication protocol parameters, etc. After configuration is completed, perform parameter verification to ensure consistency with on-site requirements.

3. Online testing: Connect on-site sensors and actuators, simulate normal operating conditions, test the signal acquisition accuracy, control command output accuracy, and communication link stability of the testing module; For closed-loop control scenarios, PID parameter tuning is required to ensure that the control response speed and stability meet the standards.

4. Redundancy testing (if configured): Simulate a main module failure, check the switching response time of the redundant module and the system operating status after switching, to ensure that the redundant function is normal and reliable.

Maintenance and troubleshooting

5.1 Key points of daily maintenance

-Regular inspection: Conduct a weekly visual inspection of the module to check the status of the panel indicator lights, whether the wiring terminals are loose, and whether there is dust accumulation on the surface of the module; Check the grounding status and cable connection status once a month, and promptly deal with loose or aged wiring.

-Cleaning and maintenance: When cleaning the module, power off first, use a dry brush or compressed air to remove surface dust, and strictly prohibit the use of wet cloths or corrosive cleaning agents to avoid damaging the module circuit.

-Environmental monitoring: Regularly check the temperature, humidity, and dust situation of the installation environment. If the environment exceeds the tolerance range of the module, timely measures such as cooling, dehumidification, or dust prevention should be taken.

5.2 Common faults and troubleshooting methods

Fault phenomenon

Possible reasons

treatment method

After power on, the red light stays on and cannot be self checked

Abnormal power supply voltage, reverse polarity of power supply, internal module malfunction

Check the voltage and polarity of the power supply and replace it with a qualified power supply; If the problem persists, contact the manufacturer for maintenance or module replacement

Inaccurate signal acquisition

Loose wiring, signal cable interference, I/O channel failure

Tighten the wiring terminals and check the grounding condition of the signal cable shielding layer; Replace the backup I/O channel for testing and troubleshoot channel faults

Communication interruption

Mismatched communication parameters, damaged communication cables, interface failures

Verify communication protocol, baud rate, and other parameters; Replace the communication cable and check the interface connection status; Test whether the interface is normal

Abnormal control command output

Program logic error, output channel failure, actuator failure

Check the control program logic and correct errors; Test the output channel signal; Check the working status of the actuator

5.3 Maintenance precautions

The module contains precision electronic circuits, and non professionals are strictly prohibited from disassembling them; If there is a malfunction that cannot be self inspected, it is necessary to contact authorized repair institutions or manufacturers in Yokogawa for maintenance to avoid unauthorized disassembly and expansion of the malfunction. The warranty period for the module is 12 months. If there is a malfunction due to product quality issues during the warranty period, you can apply for free repair or replacement with the purchase voucher.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com