Rolls-Royce Panel Control - Panel Control

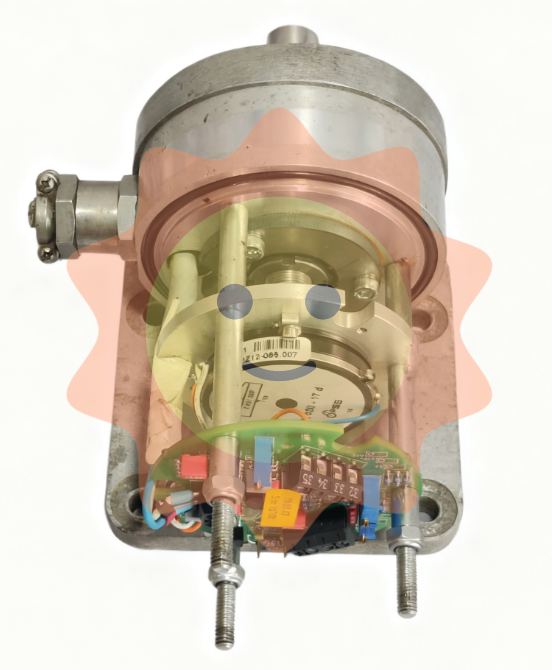

The Rolls-Royce Panel Control stands as a pinnacle of advanced automation technology, engineered specifically for demanding applications in the power industry, petrochemical sectors, and general automation environments. This robust control panel offers exceptional input/output (I/O) capacity, featuring up to 128 digital and analog I/O channels that ensure seamless integration with complex industrial systems. Designed with durability in mind, the Panel Control boasts an IP65-rated enclosure, safeguarding critical electronics against dust, moisture, and harsh operational conditions commonly encountered in petrochemical plants and power generation facilities. Its high-performance processing unit ensures rapid data acquisition and real-time control, allowing for optimized system responsiveness and minimal latency in critical automation tasks. One of the key technical highlights of the Rolls-Royce Panel Control is its modular architecture that supports flexible scalability, enabling customization based on specific plant requirements. This adaptability is complemented by its advanced diagnostic capabilities, which provide continuous system health monitoring and predictive maintenance alerts, thereby reducing downtime and enhancing overall operational efficiency. With integrated communication protocols including Modbus TCP/IP, PROFIBUS, and CAN bus, the Panel Control facilitates smooth interoperability with existing Rolls-Royce automation products and third-party systems alike.

In real-world scenarios, the Rolls-Royce Panel Control excels in managing complex power generation systems, from turbine control to grid synchronization, delivering reliable performance under high electrical loads. Its rugged design and advanced fault tolerance make it ideal for petrochemical refinery automation, where precision and safety are paramount. Additionally, the Panel Control’s ease of integration with Rolls-Royce’s broader automation ecosystem lends itself well to general automation tasks such as conveyor control, process monitoring, and environmental system regulation, ensuring consistent productivity in diverse industrial applications. Compared to other models within the Rolls-Royce portfolio, the Panel Control stands out for its superior scalability and enhanced communication flexibility. For instance, while the Rolls-Royce CANMAN CCN-11 excels in communication networking, and the Rolls-Royce MPC-200 (A 7021100) provides robust motor protection and control, the Panel Control uniquely combines these functionalities with expanded I/O capacity and modular design, making it an all-encompassing solution for integrated automation. Furthermore, models like the Rolls-Royce UN925 and Rolls-Royce UN924 are specialized controllers focusing on specific propulsion and power management tasks; however, the Panel Control’s versatility allows it to bridge multiple operational domains, from power management to process automation.

Alongside the Rolls-Royce Panel Control, we also offer complementary products such as the Rolls-Royce RPM40017 for precise rotational speed monitoring, the Rolls-Royce PSR for pressure sensing, and the Rolls-Royce UMAS-V system for advanced marine automation. The Rolls-Royce H1111.0203 and Rolls-Royce 222-653 units provide additional support in control and monitoring, enhancing the overall reliability of integrated systems. For enhanced operator interface and diagnostics, the Rolls-Royce HELICON X3 UNIT 91 offers intuitive visualization capabilities, while the Rolls-Royce BPCS-0401N-001 ensures stringent safety automation functions. These products, when combined with the Panel Control, create a comprehensive automation suite tailored for rigorous industrial demands. The application of the Rolls-Royce Panel Control in power industry, petrochemical, and general automation environments demonstrates its adaptability and performance excellence. In power plants, it manages everything from turbine speed regulation to emergency shutdown protocols, ensuring compliance with strict safety standards. Within petrochemical plants, it orchestrates complex process sequences, maintaining optimal reaction conditions and safeguarding against hazardous events. Its role in general automation extends to factory floor control, environmental systems, and batch processing, highlighting the versatility of Rolls-Royce automation products.

In summary, the Rolls-Royce Panel Control is an indispensable automation solution offering unmatched I/O capacity, durability, and performance tailored for the power industry, petrochemical sector, and general automation applications. Its modularity, advanced diagnostic tools, and communication versatility provide a unique advantage over other Rolls-Royce models such as the UN925, MPC-200, CANMAN CCN-11, and RPM40017. When paired with complementary products like the HELICON X3 UNIT 91 and BPCS-0401N-001, it forms a powerful ecosystem designed to optimize industrial operations, enhance safety, and improve productivity. Choosing the Rolls-Royce Panel Control ensures a future-proof investment backed by the legacy of trusted Rolls-Royce automation products.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-