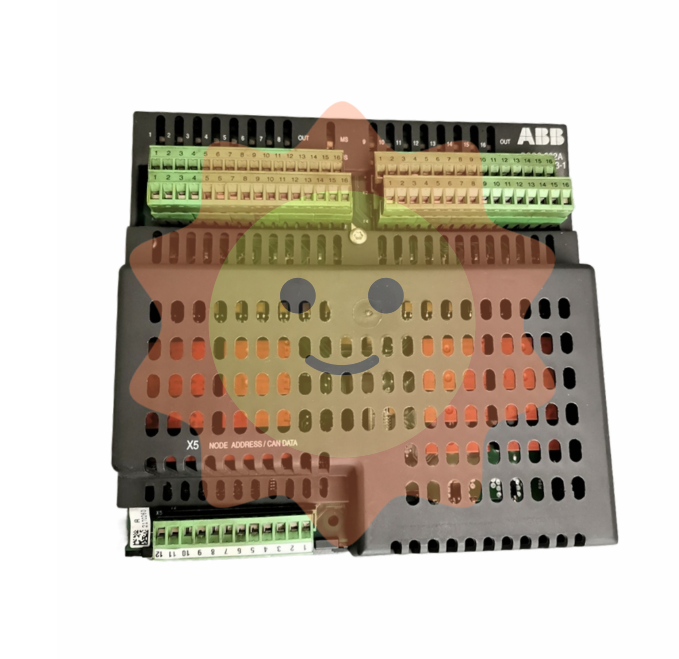

The ABB DSU14 plays a key role in industrial automation as a feature-rich, high-performance control module. Designed to meet the demanding needs of high-performance industrial automation systems, it provides a reliable and precise control solution for a wide range of manufacturing environments.

ABB DSU14 High-performance control module for industrial automation

Electrical Characteristics

Voltage range: DSU14 supports a wide input voltage range of 10-30V DC, which can be adapted to a variety of power supplies to ensure stable operation under different power supply conditions. Whether it is the common 24V DC power supply, or 12V or 30V power supply in some special applications, DSU14 can be well compatible, reducing the risk of system failure due to power mismatch.

Current Output: With 0 - 20mA output capability, DSU14 meets the needs of driving a variety of actuators and devices. In industrial automation scenarios, such as controlling the opening of regulating valves, driving small motors, etc., this output capability provides a stable and accurate control signal to ensure that the equipment operates as expected.

Power Requirements: Low power consumption during operation effectively reduces energy costs while ensuring high-performance computing and processing capabilities, in line with modern industrial requirements for energy conservation.

Communication ability

Protocol support: It integrates various communication protocols such as Modbus and Profibus, etc. Modbus protocol is widely used, which enables DSU14 to conveniently access all kinds of equipments and systems that support this protocol and realize data interaction. Profibus protocol is highly recognized in the field of industrial automation, especially suitable for industrial field bus communication, which can ensure efficient communication between DSU14 and field devices such as sensors and actuators, and ensure the real-time and reliability of the system.

Communication rate: For Profibus DP, the transmission rate can reach up to 12 Mbit/s, which is suitable for high-speed data interaction with remote I/O, drives and motor control devices; Profibus PA has a fixed transmission rate of 31.25 kbit/s, which is specially designed for connecting bus-powered two-wire field devices, such as transmitters and actuators, and guarantees communication stability while taking care of field devices, such as sensors and actuators. This ensures stable communication while taking into account the low power consumption and long-distance transmission requirements of field devices.

Environmental adaptability

Temperature range: It can operate in temperatures from -25°C to +70°C, and some versions can even operate stably in extreme temperatures from -40°C to +85°C. This makes it adaptable to high-temperature melting. This makes it suitable for harsh industrial environments such as high temperature furnace shops and low temperature cold rooms, and ensures that the automation system is stable all year round.

Protection level: IP65 protection level, which can effectively prevent dust and water splash. In dusty mines, cement factories, or humid food processing plants, ships and other environments, DSU14 can resist the intrusion of dust particles and the impact of water splashing, avoiding short circuit or corrosion of the internal circuit, and prolonging the service life.

Functional features

Data Acquisition and Processing: With high-speed data acquisition capability, DSU14 can quickly capture process data within 10ms to provide data support for real-time monitoring and control. Through the built-in high-performance processor, the collected data can be quickly analyzed and processed, and control commands can be issued in time according to the preset logic to optimize the industrial production process.

Control Output Mode: Provides two types of control outputs: relay and analog. Relay output can control the on/off of high-voltage and high-current devices, such as the start/stop of motors; analog output can realize continuous and precise adjustment of devices, such as adjusting the opening of valves to control the flow rate, to meet the diversified needs of different application scenarios.

Remote Ethernet boot: Utilizing the extended ROM BIOS, the processor can boot from a network server, supporting PXE and BOOTP, DHCP (TCP / IP) and other network boot protocols. Convenient for remote maintenance and system upgrade, engineers do not need to visit the site in person, through the network can complete the initialization of the device and program updates, saving a lot of time and labor costs.

Mechanical Specifications

Dimensions: Overall dimensions of 15cm x 10cm x 5cm (L x W x H), compact design allows it to be easily installed in space-limited control cabinets or inside the equipment, saving installation space and improving space utilization.

Weight: Weighing only 0.5kg, the light weight is easy to transport and install, and will not bring too much burden to the overall structure in some mobile equipment or aerial work equipment that requires the weight of the equipment.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-