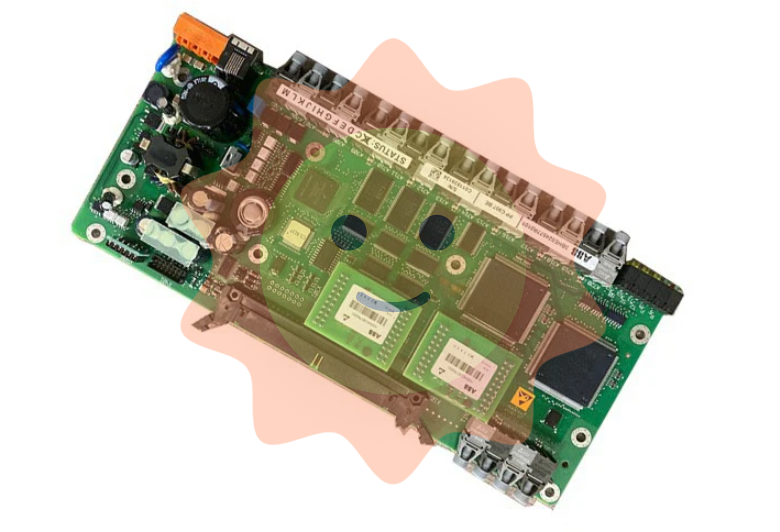

The ABB HIEE401807R0001 advanced power electronic module is a core power conversion unit developed by ABB based on third-generation wide bandgap semiconductor technology, specifically designed for energy conversion and control in medium and high voltage power systems and industrial drive fields. This module integrates high-performance IGBT (Insulated Gate Bipolar Transistor) chips, precision drive circuits, real-time protection mechanisms, and intelligent monitoring functions, which can achieve efficient conversion between AC and DC, voltage/frequency regulation, and reactive power compensation. It seamlessly cooperates with the upper system through ABB's dedicated control bus, and has the technical advantages of high power density, low loss, and high reliability. It is widely used in scenarios such as new energy grid connection, flexible DC transmission, industrial variable frequency drive, and power quality management, and is a key core component for building efficient, stable, and intelligent power systems.

ABB HIEE401807R0001 Advanced Power Electronics Module

Product Overview

The ABB HIEE401807R0001 advanced power electronic module is a core power conversion unit developed by ABB based on third-generation wide bandgap semiconductor technology, specifically designed for energy conversion and control in medium and high voltage power systems and industrial drive fields. This module integrates high-performance IGBT (Insulated Gate Bipolar Transistor) chips, precision drive circuits, real-time protection mechanisms, and intelligent monitoring functions, which can achieve efficient conversion between AC and DC, voltage/frequency regulation, and reactive power compensation. It seamlessly cooperates with the upper system through ABB's dedicated control bus, and has the technical advantages of high power density, low loss, and high reliability. It is widely used in scenarios such as new energy grid connection, flexible DC transmission, industrial variable frequency drive, and power quality management, and is a key core component for building efficient, stable, and intelligent power systems.

Core Basic Parameters

Product Model

HIEE401807R0001

manufacturer

ABB Group

Power device type

Third generation IGBT chip (1200V/1700V optional), using field cut off technology

rated current

500A (continuous operation), 1200A (peak current, duration ≤ 10ms)

rated voltage

AC 380V-1140V/DC 600V-1500V (suitable for different application scenarios)

switching frequency

1kHz-20kHz (programmable adjustment, supports adaptive frequency modulation)

Power conversion efficiency

≥ 98.5% (under rated load conditions)

topological structure

Three phase full bridge topology, supporting two-level/three-level mode switching

drive circuit

Optocoupler isolation drive with active clamp protection function

monitoring parameters

Input/output voltage, current, IGBT junction temperature, module temperature, switch status

communication interface

EtherCAT (real-time control), CANopen (status feedback), RS485 (configuration debugging)

power control

DC 24V ± 10%, power ≤ 50W

Working temperature range

-40 ℃~125 ℃ (IGBT junction temperature), -20 ℃~85 ℃ (module housing)

Protection level

IP20 (module body), IP54 (version with heat dissipation shell optional)

Installation method

Heat sink fitting installation (supporting water/air cooling), standard rail assisted fixation

Core functional characteristics

1. Efficient energy conversion and low loss operation

The module adopts third-generation IGBT chips and optimized packaging technology, combined with field cut off structure design, significantly reducing IGBT switching losses and conduction losses, and achieving a power conversion efficiency of over 98.5% under rated load. Supports a wide range of programmable switching frequencies from 1kHz to 20kHz, combined with ABB's patented Space Vector Pulse Width Modulation (SVPWM) algorithm, which can adaptively adjust the switching frequency according to load changes, ensuring output waveform quality while minimizing energy consumption. It is particularly suitable for efficiency demanding scenarios such as new energy generation and industrial frequency conversion.

2. Comprehensive real-time protection mechanism

Integrate multiple hardware level and software level protection functions to build a three-dimensional safety protection system: at the hardware level, it has IGBT overcurrent protection (short circuit current quickly shuts off, response time ≤ 1 μ s), overvoltage protection (active clamp suppression switch overshoot), and over temperature protection (real-time monitoring of junction temperature, automatic derating in case of over temperature); At the software level, it supports input voltage abnormality protection, load fault protection, and communication interruption safety mode. When a fault is detected, the module immediately cuts off power output and triggers an alarm signal, while storing fault data to provide a basis for subsequent troubleshooting, effectively avoiding device damage and system crashes.

3. High precision power control capability

Based on ABB's advanced current loop and voltage loop dual closed-loop control algorithm, precise adjustment of output voltage and current is achieved, with voltage control accuracy of ≤± 0.5% FS and current control accuracy of ≤± 1% FS. It supports independent control of active power and reactive power, and can flexibly operate in multiple modes such as constant voltage source, constant current source, and constant power. It can not only meet the power regulation needs of new energy grid connection, but also adapt to the precise control of motor speed and torque in industrial drive. It can also be used for reactive power compensation and harmonic suppression in power quality control.

4. Intelligent state monitoring and health management

Built in high-precision sensors and data acquisition units, real-time monitoring of core parameters such as IGBT junction temperature, module housing temperature, input/output voltage and current, switch status, etc., and uploading data to the control unit through EtherCAT bus. Equipped with device health status assessment function, based on IGBT junction temperature cycle times, switch loss accumulation and other data, ABB dedicated algorithm is used to predict the remaining life of the module, issue maintenance warnings in advance, support the implementation of predictive maintenance strategies, and reduce unplanned downtime.

5. High reliability and adaptability to harsh environments

Adopting industrial grade reinforced design, the power circuit and control circuit achieve electrical isolation of 3kVrms or more, effectively resisting common mode interference and electromagnetic radiation; IGBT chips undergo wide temperature screening from -55 ℃ to 150 ℃, and are equipped with temperature compensation circuits and moisture-proof coatings inside the module. They can operate stably within the temperature range of -20 ℃ to 85 ℃ for the housing. Through IEC 61800-5-1 variable frequency drive standard certification and IEC 61000-6-2 anti-interference certification, it adapts to complex electromagnetic environments and temperature fluctuation scenarios such as new energy power stations and industrial workshops.

6. Flexible system integration and expansion

Supporting parallel operation of multiple modules and achieving power sharing through ABB's dedicated current sharing technology, the system capacity can be easily expanded to several megawatts, meeting the needs of large-scale industrial drives and grid level applications. Compatible with mainstream control systems such as ABB ACS880 series frequency converters and PCS6000 series energy storage converters, it achieves millisecond level response of control instructions through EtherCAT real-time bus, and supports third-party controller access. It has open communication protocols and standardized interfaces, simplifying the system integration process.

7. Convenient debugging and operation

Equipped with ABB PowerSuite debugging software, it supports configuring module parameters through PC or mobile terminals, including switching frequency, control mode, protection threshold, etc. The software has built-in waveform display function, which can observe input and output voltage and current waveforms in real time. The module body is equipped with status indicator lights and fault diagnosis interfaces. By combining the indicator lights, the operating status and basic fault types can be quickly determined. Combined with software diagnostic functions, the fault point can be accurately located, reducing the difficulty and time cost of operation and maintenance.

Applicable scenarios

-New energy grid connection: photovoltaic power plant inverters, wind power generation inverters, achieve efficient conversion of DC and AC electricity and smooth grid connection

-Energy storage system: Lithium battery/flow battery energy storage converter (PCS), completes power control during charging and discharging processes, and enhances grid peak shaving capability

-Industrial variable frequency drive: Variable frequency control of large fans and pumps in steel mills and chemical plants to achieve motor speed regulation and energy-saving operation

-Power quality management: Static Var Generator (SVG), Active Power Filter (APF), compensating for reactive power in the power grid and suppressing harmonic interference

-Rail transit: Metro and high-speed rail traction inverters provide stable and adjustable DC power for traction motors, ensuring smooth train operation

-Flexible DC transmission: Medium voltage flexible DC grid converter valve unit, achieving efficient interconnection and power transmission in different power grid regions

-Emergency power supply: rectifier and inverter units for diesel generators and mobile power stations to ensure stable power quality during emergency power supply

Precautions for use

1. Before installation, it is necessary to confirm that the module model matches the voltage level and power requirements of the application scenario. Power terminals and control terminals should be strictly distinguished according to the product manual. The power circuit should be connected with copper bars and insulated, and the control circuit should be wired with shielded cables.

2. The module must be reliably attached to the compatible heat sink, and the contact surface should be coated with thermal conductive silicone grease to ensure a thermal resistance of ≤ 0.1 ℃/W. Depending on the power level, air cooling or water cooling heat dissipation schemes should be selected to avoid IGBT junction temperature exceeding 125 ℃.

Before the first operation, parameter initialization configuration, including control mode, rated voltage and current, protection threshold, etc., must be completed through PowerSuite software. It is necessary to conduct no-load and light load tests to verify that the output waveform and control accuracy are normal before connecting to full load operation.

4. During operation, it is necessary to regularly monitor parameters such as module temperature, input and output voltage and current, check the operating status of the cooling system, ensure that the fan is not blocked and the water cooling system is leak free, and tighten the module connection bolts every six months to prevent overheating caused by increased contact resistance.

5. When the module issues a fault alarm, the input power should be immediately cut off, and the fault code should be read through debugging software to investigate the cause of the fault (such as load short circuit, heat dissipation failure, abnormal drive circuit, etc.). It is forbidden to power on again before troubleshooting.

When performing software upgrades or parameter modifications, it is necessary to first backup the current configuration parameters. During the upgrade process, ensure the stability of the control power supply and prohibit interrupting the communication link. After the upgrade is completed, functional verification is required to avoid module damage caused by abnormal parameters.

7. Module maintenance must be carried out by professionals with qualifications for power electronic equipment debugging. Before maintenance, the module must be discharged. Non professionals are prohibited from disassembling the module or touching power devices without authorization to avoid high-voltage electric shock and device damage.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-