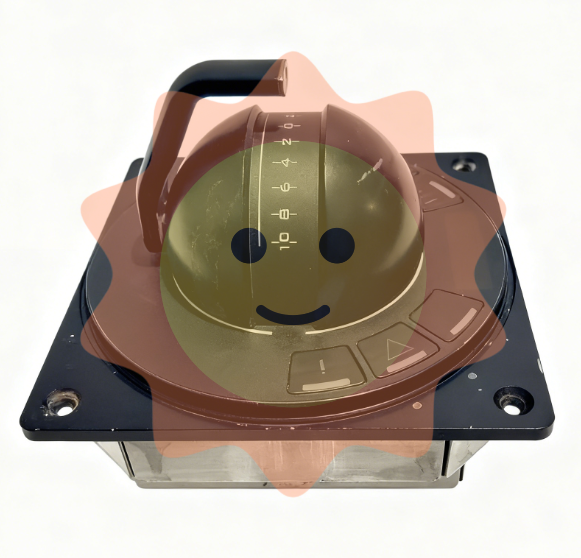

Rolls-Royce UN 911.1 - INTEL INSIDE PENTIUM CINET M-600

The Rolls-Royce UN 911.1 stands as a pinnacle in Rolls-Royce automation products, engineered specifically to meet the demanding requirements of the power industry, petrochemical plants, and general automation sectors. This model is celebrated for its robust input/output (I/O) capacity, exceptional durability, and superior performance metrics, making it an indispensable component in high-stakes industrial environments. At its core, the Rolls-Royce UN 911.1 boasts an advanced I/O system capable of handling up to 256 discrete inputs and outputs, alongside 64 analog channels. This extensive capacity ensures seamless integration with complex process control systems, facilitating precise monitoring and control. The device operates with a response time of under 5 milliseconds, enabling real-time data processing and control actions critical in automation tasks. Built with high-grade industrial components, the UN 911.1 is rated for continuous operation under extreme conditions, including temperatures ranging from -40°C to +85°C and high humidity environments, underscoring its durability. Additionally, its rugged chassis is designed to withstand vibrations and shocks common in petrochemical and power generation facilities, ensuring reliability and longevity.

In practical applications, the Rolls-Royce UN 911.1 excels in scenarios requiring stringent control and monitoring, such as turbine management in power plants, safety interlocks in petrochemical refineries, and automated process control in general manufacturing automation. For instance, within the power industry, it integrates seamlessly with turbine governors and generator excitation systems, providing stable operational control and minimizing downtime. In petrochemical settings, it supervises critical safety systems, maintaining regulatory compliance and safeguarding personnel. Its versatility extends to general automation tasks where precision and reliability are paramount, such as automated assembly lines and large-scale HVAC system management. Comparatively, the UN 911.1 distinguishes itself from other Rolls-Royce models through its superior I/O capacity and enhanced environmental resilience. While models like the Rolls-Royce UN 925 and UN 927 offer robust automation solutions, the UN 911.1 surpasses them with higher channel counts and faster response times, making it ideal for more complex or rapidly changing process environments.

Unlike the Rolls-Royce un914.11a, which is optimized for moderate automation demands, the UN 911.1 is designed for high-intensity industrial applications requiring stringent performance standards. Additionally, where the Rolls-Royce RRADI16 provides specialized diagnostic capabilities, the UN 911.1 focuses on comprehensive control and monitoring, complementing each other in integrated system setups. Alongside the Rolls-Royce UN 911.1, we also offer models like the Rolls-Royce MEF-101 and Rolls-Royce DEP.STEERING GEAR-TENFJORD, which provide additional control solutions for marine and industrial steering applications. The Rolls-Royce 5880-PC1020 Rév. B and 5880-PC1019 serve as robust interface cards that enhance connectivity options for the UN 911.1, ensuring smooth integration into existing automation architectures. For environments requiring advanced data processing, the Rolls-Royce HELICON and HELICON 6865 units offer complementary computational power that can be paired with the UN 911.1 for enhanced system intelligence. Furthermore, the Rolls-Royce CCP-FPGI and RPM 02 modules provide specialized signal processing and rotational speed measurement, which can augment the capabilities of the UN 911.1 in power and petrochemical applications.

The application of UN 911.1 in power industry, petrochemical, and general automation is further supported by its compatibility with Rolls-Royce’s comprehensive automation ecosystem, including the Rolls-Royce MT-000551-A and Rolls-Royce SPA-1, which facilitate system diagnostics and preventive maintenance protocols. This interoperability ensures that operators can implement a layered approach to automation, combining the strengths of multiple Rolls-Royce products for a resilient and efficient control environment. In summary, the Rolls-Royce UN 911.1 sets a new standard for industrial automation with its expansive I/O capabilities, rugged reliability, and rapid response performance. Its specialized design makes it the preferred choice for critical applications in the power industry, petrochemical plants, and general automation sectors. By integrating seamlessly with other Rolls-Royce automation products such as the MEF-101, HELICON series, and DEP.STEERING GEAR-TENFJORD, the UN 911.1 delivers a comprehensive, scalable solution that meets the evolving needs of modern industrial automation. For organizations seeking a dependable automation platform with proven performance and versatility, the Rolls-Royce UN 911.1 remains the definitive choice.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-