As the "safety guard" of turbomachinery, the core function of turbine protection relay is to collect monitoring signals from various key parts of the turbine, and evaluate the equipment's operating status in real time through internal precise calculation and logical judgment. When dangerous operating conditions such as excessive speed, vibration, and axial displacement occur, the ability to issue shutdown instructions or alarm signals within milliseconds, cut off the source of danger, and prompt operation and maintenance personnel to handle it is the last important line of defense to ensure the safe and stable operation of the turbine.

The GE IS200SPROH1AAB MRP663860 relay is developed based on GE's mature Mark VIe control system platform, adopting modular and intelligent design. It not only seamlessly integrates with GE series monitoring systems, but also supports personalized protection logic configuration, which can adapt to the needs of different models and working conditions of turbines, balancing universality and specificity.

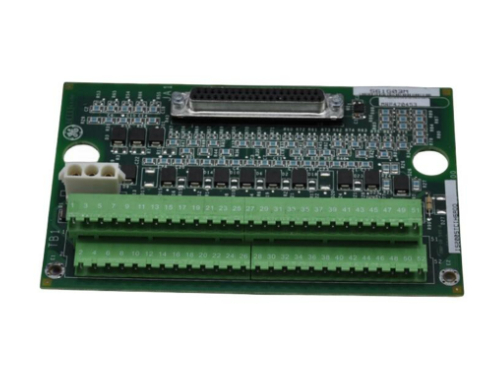

GE IS200SPROH1AAB MRP663860 Turbine Protection Relay

Basic Overview of Equipment

As the "safety guard" of turbomachinery, the core function of turbine protection relay is to collect monitoring signals from various key parts of the turbine, and evaluate the equipment's operating status in real time through internal precise calculation and logical judgment. When dangerous operating conditions such as excessive speed, vibration, and axial displacement occur, the ability to issue shutdown instructions or alarm signals within milliseconds, cut off the source of danger, and prompt operation and maintenance personnel to handle it is the last important line of defense to ensure the safe and stable operation of the turbine.

The GE IS200SPROH1AAB MRP663860 relay is developed based on GE's mature Mark VIe control system platform, adopting modular and intelligent design. It not only seamlessly integrates with GE series monitoring systems, but also supports personalized protection logic configuration, which can adapt to the needs of different models and working conditions of turbines, balancing universality and specificity.

Core technical parameters

The technical parameters directly determine the monitoring accuracy and protection performance of the protective relay. The following is the key parameter information of GE IS200SPROH1AAB MRP663860 turbine protection relay, providing reference for equipment selection, commissioning, and operation and maintenance:

1. Enter specifications

-Input signal types: Supports speed signals (magneto electric/photoelectric sensors), vibration signals (piezoelectric acceleration sensors), displacement signals (eddy current sensors), as well as analog/switch signals such as temperature and pressure;

-Number of input channels: 8 analog inputs (including speed, vibration, etc.)+4 switch inputs (status feedback), with independent channel isolation design to prevent signal interference;

-Speed measurement range: 0~30000r/min (can be extended to higher ranges through software), suitable for high-speed and low-speed turbines;

-Vibration measurement range: 0~50mm/s (peak to peak), measurement accuracy ± 0.1mm/s;

-Displacement measurement range: -2.5mm~+2.5mm, measurement accuracy ± 0.001mm;

-Signal input impedance: Analog input ≥ 10M Ω, speed signal input 500 Ω~1k Ω, matching the output characteristics of mainstream sensors.

2. Output specifications

-Output signal type: relay contact output (passive)+analog feedback output (4-20mA)+digital communication output;

-Relay output: 6 normally open/normally closed selectable contacts, with contact capacities of AC 250V/5A and DC 24V/10A, meeting high-power control requirements such as shutdown commands and alarm signals;

-Analog output: 2 channels of 4-20mA standard signals, corresponding to the actual values of monitoring parameters, used for external display instruments or DCS systems;

-Response time: Protection action response time ≤ 10ms, ensuring rapid intervention in hazardous conditions.

3. Electrical and environmental parameters

-Power supply: DC 24V ± 15% or AC 220V ± 10%, dual power redundancy design (optional) to ensure power supply reliability;

-Isolation performance: Triple optoelectronic isolation is used between input, output, and power supply, with an isolation voltage of ≥ 2500V AC (1 minute) and strong anti-interference ability;

-Working temperature range: -10 ℃~70 ℃, suitable for machine room and on-site installation environment;

-Humidity range: 5%~90% RH (no condensation), can operate stably in humid industrial environments;

-Protection level: IP30 (cage installation), requires cooperation with the control cabinet to achieve dust and water protection;

-Electromagnetic compatibility: Complies with standards such as IEC 61000-4-2 (ESD) and IEC 61000-4-3 (RFI), and operates without malfunction in strong electromagnetic environments.

4. Communication and interface parameters

-Communication Protocol: Supports mainstream industrial communication protocols such as Modbus RTU, PROFINET, EtherNet/IP, and can communicate in real-time with PLC and DCS systems;

-Communication interface: 1 RJ45 Ethernet interface (10/100Mbps)+1 RS485 serial interface, supporting data upload and remote configuration;

-Data update rate: Communication data update rate ≤ 100ms, ensuring real-time acquisition of device status by the monitoring system.

Core functions and features

1. Multi parameter precise monitoring and comprehensive protection

The relay integrates multi-dimensional monitoring functions such as speed, vibration, displacement, temperature, etc. It uses high-precision signal acquisition chips and digital filtering algorithms to effectively filter out on-site noise interference and ensure that the monitoring data error is ≤ 0.5%. Built in multiple protection logics (such as overspeed protection, vibration over limit protection, axial displacement protection, etc.), supporting user-defined protection thresholds and delay times, meeting the safety standards of different turbines (such as API 612, ISO 10436, etc.).

2. Fast response and reliable action

For emergency conditions such as turbine speed exceeding the limit, the relay adopts a hardware priority processing circuit, skipping the complex software calculation process, and achieving a rapid response of ≤ 10ms; The relay contacts are made of silver alloy material, which has the characteristics of arc resistance and wear resistance, ensuring reliable contact attraction/disconnection during protection action, and avoiding protection failure caused by contact adhesion. At the same time, it has a built-in "fault self diagnosis" function. If there is a circuit fault, it will immediately issue a "device fault" alarm to avoid false protection or missed protection.

3. Intelligent operation and convenient maintenance

Equipped with a 2.4-inch LCD display screen and physical operation buttons, it supports on-site viewing of real-time monitoring data, protection logic parameters, and historical fault records (can store 1000 fault information, including timestamps); Remote parameter configuration, logic modification, and firmware upgrade can be achieved through GE specific configuration software (such as ToolboxST) without the need for on-site disassembly of equipment; Built in "calibration mode" supports quick channel accuracy calibration through standard signal sources, reducing operational difficulty.

4. Powerful system compatibility and scalability

As a dedicated module for the GE Mark VIe control system, this relay can be directly inserted into the system rack and communicate with the controller at high speed through the backplane bus without the need for additional communication modules; Support integration with third-party DCS systems (such as Siemens PCS 7, Emerson DeltaV) through standard communication protocols; Modular design allows for the expansion of input/output channels according to requirements, or the addition of functional modules such as flame monitoring and oil system protection, to enhance system adaptability.

5. Industrial grade safety and stability

Adopting industrial grade reinforced shell and PCB board triple anti coating (anti salt spray, anti moisture, anti dust) to adapt to harsh environments such as petrochemicals and offshore platforms; The power circuit is designed with overvoltage and overcurrent protection, and the signal input circuit has surge suppression function (compliant with IEC 61000-4-5 standard, capable of withstanding 2kV surge impact); Through safety certifications such as UL 61010-1 and IEC 61508, it meets the reliability requirements of high-end applications such as nuclear grade and military grade.

Typical application scenarios

-Electric power industry: used for safety monitoring of steam turbines in thermal power plants and gas turbines in gas-fired power plants, monitoring faults such as speed exceeding the limit (such as 110% rated speed), shaft vibration exceeding the limit, and excessive axial displacement, triggering emergency shutdown protection to avoid turbine runaway accidents;

-Petrochemical industry: Suitable for the gas turbine and compressor turbine parts of catalytic cracking units, monitoring vibration, displacement, and oil temperature parameters. When equipment surge or unbalanced vibration occurs, timely alarms are issued and the feed is cut off to protect the turbine blades from damage;

-Aerospace field: Used for turbine protection on ground test benches for aircraft engines, accurately monitoring vibration and displacement signals at high speeds (such as 20000r/min or above) to ensure safe and controllable testing processes;

-Hydropower industry: applied to monitor the main shaft of water turbines. When the main shaft swing exceeds the standard or the speed is abnormal, it triggers the closure of guide vanes or emergency shutdown action to prevent the turbine from escaping;

-Iron and Steel Metallurgy Industry: Used for protecting turbine blowers in blast furnace blast stations, monitoring equipment vibration, bearing temperature, and speed, ensuring continuous and stable operation of the blast system, and avoiding blast furnace air interruption accidents.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-