ABB P8431 is a high-performance controller module developed by ABB for industrial automation process control. It belongs to the ABB Advance OCS or Freelance control system family and is the core unit for implementing complex industrial process logic control, process regulation, and equipment linkage. This module integrates advanced embedded processing technology, redundant fault-tolerant design, and flexible configuration capabilities, and is widely used in fields such as petrochemicals, metallurgy, power, and municipal engineering that require high control reliability. It provides a precise and stable control core for industrial production processes and is a key hub connecting on-site equipment and upper level monitoring systems.

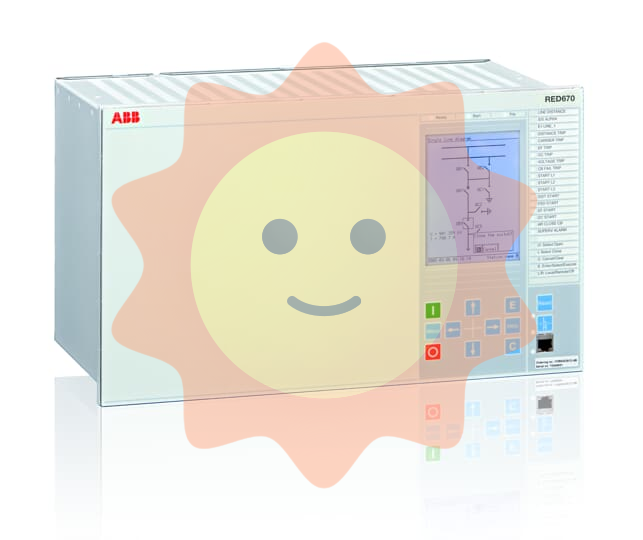

ABB P8431 controller module

Product Overview

ABB P8431 is a high-performance controller module developed by ABB for industrial automation process control. It belongs to the ABB Advance OCS or Freelance control system family and is the core unit for implementing complex industrial process logic control, process regulation, and equipment linkage. This module integrates advanced embedded processing technology, redundant fault-tolerant design, and flexible configuration capabilities, and is widely used in fields such as petrochemicals, metallurgy, power, and municipal engineering that require high control reliability. It provides a precise and stable control core for industrial production processes and is a key hub connecting on-site equipment and upper level monitoring systems.

As a specialized controller module, P8431 has powerful computing processing capabilities and rich interface resources. It is compatible with ABB's full range of I/O modules and supports multiple industrial communication protocols. It can achieve various control tasks from simple logic control to complex multivariable coordinated control according to the production needs of different industries, providing users with efficient and reliable control solutions.

Core functions and technical features

2.1 Core Control Functions

-Multi type control algorithm support: Built in rich control algorithm library, covering continuous control (such as PID, cascade PID, feedforward control), discrete control (such as ladder diagram, function block diagram, sequential function diagram) and advanced control (such as fuzzy control, predictive control), etc., can meet the control needs of different process scenarios, such as temperature and pressure cascade control of chemical reaction kettle, sequential start stop control of metallurgical production line, etc.

-High speed data processing and real-time control: Equipped with a high-performance 32-bit embedded processor, the computing speed can reach millions of instructions per second, which can quickly collect on-site I/O signals and execute control logic. The control cycle can be as low as milliseconds, ensuring timely response to rapidly changing working conditions in industrial processes and effectively improving control accuracy.

-Redundancy control and fault tolerance capability: Supports controller hot redundancy configuration (1+1 redundancy). When the main controller fails, the backup controller can automatically switch without disturbance, with a switching time of less than 100ms, ensuring uninterrupted control process; Simultaneously equipped with I/O channel fault diagnosis and isolation functions, further enhancing the reliability of the system.

-Flexible I/O expansion and management: Digital and analog I/O modules can be flexibly expanded through standardized bus interfaces (such as PROFIBUS, Ethernet/IP), supporting centralized management of up to hundreds of I/O points; Support hot swapping of I/O modules for easy system maintenance and upgrades, reducing downtime.

2.2 Key Technical Features

-Powerful communication and interconnection capabilities: Integrated with multiple communication interfaces, supporting mainstream industrial communication protocols such as PROFIBUS-DP, Modbus TCP, EtherNet/IP, etc., it can achieve data exchange with on-site intelligent devices (such as sensors, actuators, frequency converters), upper level SCADA systems, and enterprise MES systems, and build a full level industrial communication network.

-High reliability hardware design: Industrial grade anti-interference components are used, and the core circuit undergoes strict electromagnetic compatibility (EMC) testing to resist interference such as electromagnetic radiation and voltage fluctuations in industrial sites; The working temperature range is -10 ℃ to 60 ℃, and the relative humidity adaptation range is 10% -95% (no condensation). It can adapt to harsh industrial environments, and the average time between failures (MTBF) exceeds 200000 hours.

-Convenient configuration and debugging: Supports graphical configuration through specialized software such as ABB Control Builder or Freelance Engineering. Operators can quickly build control logic by dragging and dropping function blocks without writing complex code; The software has built-in online monitoring and debugging tools, which can view the real-time operation status, variable values, and fault information of the controller, facilitating on-site debugging and problem troubleshooting.

-Data storage and log management: Equipped with a large capacity non-volatile memory, it can store control programs, parameter configurations, and historical operating data. After power failure, the data can be saved for more than 10 years; Equipped with comprehensive logging capabilities, it can record information such as device start stop, parameter modification, fault occurrence time and type, providing data support for production traceability and system optimization.

Applicable scenarios and application advantages

3.1 Main Applicable Scenarios

The ABB P8431 controller module, with its powerful control capabilities and high reliability, is widely used in various medium to large industrial automation systems, including:

-Petrochemical industry: reaction process control, material transportation control, and safety interlock systems in refineries and chemical plants, such as temperature and pressure control in catalytic cracking units and liquid level interlock protection in storage tank areas.

-Electric power industry: boiler combustion control in thermal power plants, turbine speed regulation, substation equipment monitoring, as well as excitation control and load regulation of hydroelectric power plant hydro generator units.

-Metallurgical industry: Control of blast furnace ironmaking process in steel plants, adjustment of converter steelmaking process, speed and tension control of hot/cold rolling production lines to ensure stable and efficient metallurgical processes.

-In the field of municipal engineering: aeration control of sewage treatment plants, regulation of water purification processes, and control of pump start stop and pressure stability in urban water supply systems.

-In the field of intelligent manufacturing: equipment linkage control, production process optimization, and quality traceability system for large-scale automated production lines to improve production efficiency and product qualification rate.

3.2 Application advantages

-Improving production process stability: High precision real-time control and fast response capability can effectively suppress interference factors in industrial processes, ensure stable process parameters within the set range, and reduce product quality fluctuations.

-Ensuring production safety: A comprehensive redundant fault-tolerant design and safety interlock function can effectively avoid production accidents caused by equipment failures, especially in high-risk industries such as petrochemicals, which can significantly reduce safety risks.

-Reduce operating costs: By optimizing control algorithms to reduce material consumption and energy loss, while high reliability design reduces equipment maintenance frequency and downtime losses, the company can lower operating costs.

-Easy system upgrade and expansion: Modular design and flexible communication capabilities enable the system to quickly add I/O modules or expand control functions according to production scale expansion or process upgrade requirements, without the need for large-scale replacement of core control units.

Installation and maintenance precautions

4.1 Installation Requirements

-Before installation, it is necessary to confirm that the controller module model (P8431) matches the matching I/O module and rack model, and check that the module appearance, pins, and interfaces are not damaged; During installation, the module should be smoothly inserted into the corresponding slot of the dedicated rack, ensuring good contact between the module and the rack bus, and fastened with fixing screws to prevent poor contact caused by vibration.

-The installation environment should be selected in a well ventilated, dry, non corrosive gas, and non strong electromagnetic radiation area. At least 10cm of heat dissipation space should be reserved around the controller to avoid close installation with strong interference equipment such as frequency converters and high-power motors; If installed in a cabinet, it is necessary to ensure that the cabinet has forced ventilation or cooling fans.

-When wiring, it is necessary to strictly follow the pin definitions in the product manual, distinguish between the power supply end, communication bus end, and I/O expansion end, and ensure stable power supply voltage (usually 24V DC or 220V AC, to be confirmed according to the specific model); Communication cables should use shielded cables, with the shielding layer grounded at one end to avoid signal interference.

4.2 Maintenance points

-Regularly (recommended monthly) inspect the appearance of the controller module, clean the dust and oil stains on the surface of the module and inside the rack, check the tightness of the fixing screws and wiring terminals, and ensure that there is no looseness or oxidation.

-Verify the operating parameters, redundancy status, and log information of the controller through configuration software every quarter to confirm that there are no abnormal modifications to the control program and that the switching function of the redundant controller is normal; Backup key control parameters to prevent data loss.

-To avoid severe impacts, collisions, or electrostatic interference on the controller module, it is necessary to wear an anti-static wristband during maintenance. It is strictly prohibited to touch the module pins and interfaces with metal objects; During the operation of the system, it is prohibited to randomly plug and unplug modules. If replacement is required, a shutdown or redundant switching operation must be performed first.

-When there is a communication failure, abnormal control logic execution, or indicator light alarm in the controller, the fault log should be checked through the configuration software to preliminarily locate the cause. If a module needs to be replaced, an ABB original module of the same model should be used, and the backup parameters should be reloaded after replacement to ensure that the system resumes normal operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-