The ABB PM645B processor module is the core computing unit in the ABB AC 800M control system. As the "brain" of industrial automation control, it integrates high-performance processors and rich control functions, designed specifically for medium and large-scale industrial control scenarios. This module relies on ABB's mature technology system in the field of industrial automation, and has the characteristics of fast computing speed, high reliability, strong scalability, and good compatibility. It can accurately execute complex control algorithms, process massive industrial field data in real time, and is widely used in process control and logic control scenarios in industries such as chemical, metallurgy, power, water treatment, and papermaking. It provides core support for stable operation, efficient control, and safety assurance of production processes.

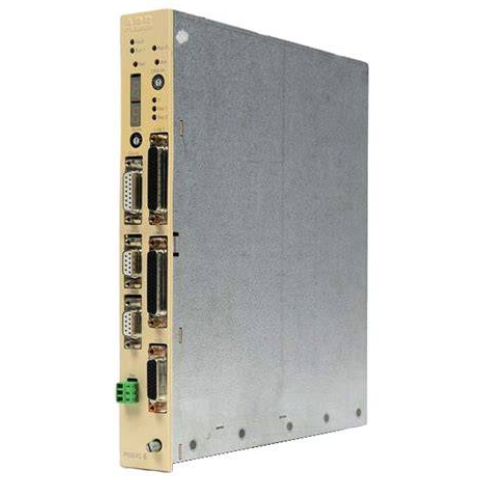

ABB PM645B processor module

Product Overview

The ABB PM645B processor module is the core computing unit in the ABB AC 800M control system. As the "brain" of industrial automation control, it integrates high-performance processors and rich control functions, designed specifically for medium and large-scale industrial control scenarios. This module relies on ABB's mature technology system in the field of industrial automation, and has the characteristics of fast computing speed, high reliability, strong scalability, and good compatibility. It can accurately execute complex control algorithms, process massive industrial field data in real time, and is widely used in process control and logic control scenarios in industries such as chemical, metallurgy, power, water treatment, and papermaking. It provides core support for stable operation, efficient control, and safety assurance of production processes.

The PM645B processor module can not only independently undertake a single control task, but also achieve multi module collaborative work and distributed control through ABB's industrial Ethernet and fieldbus technology, building a flexible and scalable control system architecture to meet the control requirements of different scale production devices. It is a key component for achieving precise control and intelligent management in modern industrial automation systems.

Core technical parameters

Product Model

PM645B

ABB AC 800M series processor module specific identification, representing a specific performance level

Core processor

High performance 32-bit RISC processor

Capable of high-speed computing, able to quickly handle complex control logic and data operations

clock rate

About 800MHz

High frequency ensures instruction execution efficiency, reduces control delay, and improves real-time performance

Memory configuration

1GB DDR3 SDRAM (running memory)+256MB Flash (non-volatile memory)

Large capacity running memory supports multitasking concurrent processing, Flash memory is used to store system programs and configuration files, and is not lost during power outages

control cycle

The minimum control cycle can reach 1ms

Meet the requirements of high-precision process control and achieve rapid response to the controlled object

Supported programming languages

IEC 61131-3 standard languages (LD, FBD, ST, SFC, IL), C/C++

Compatible with international standards and advanced programming languages, making it easy for engineers to develop and debug control programs

communication interface

2 Gigabit Ethernet ports, 1 RS232/RS485 serial port

Ethernet ports are used for system networking and data exchange, while serial ports are used for local debugging and device communication

Expansion capability

Supports up to 8 I/O expansion racks and can connect various I/O modules

Flexibly expand input and output channels to adapt to control scenarios of different scales

working power supply

DC 24V(±10%)

Adapt to industrial standard DC power supply, with strong adaptability to voltage fluctuations

Working temperature range

0℃~60℃

Adapt to the temperature environment inside industrial control cabinets to ensure stable operation

Protection level

IP20 (module itself)

It needs to be installed inside a closed control cabinet to prevent dust and foreign objects from entering

Redundant support

Support hot standby redundant configuration (in conjunction with redundant modules)

Realize disturbance free switching, improve system reliability, suitable for critical control scenarios

Core performance advantages

1. High speed computing and real-time control, precise and rapid response

The PM645B is equipped with a high-performance 32-bit RISC processor with a clock frequency of 800MHz and 1GB of large operating memory. It can simultaneously process data acquisition and control instruction output from thousands of I/O points, with a minimum control cycle of only 1ms. Whether it is complex PID regulation, logic interlock control, or batch data processing, it can quickly complete calculations and execution, effectively reducing control delays, ensuring accurate response to various parameter changes in the production process, and improving control accuracy and production stability. For example, in temperature control of chemical reaction vessels, temperature fluctuations can be captured in real time and the heating or cooling system can be quickly adjusted to control temperature deviations within ± 0.5 ℃.

2. High reliability design to ensure continuous operation

This module adopts industrial grade components and rigorous production processes, with excellent anti-interference ability and environmental adaptability, and can work stably in the temperature range of 0 ℃~60 ℃. At the same time, it supports hot standby redundancy configuration. When the main processor module fails, the redundant module can complete uninterrupted switching in milliseconds, ensuring that the control program is not interrupted and the production process is not affected, greatly improving the availability and reliability of the system. It is particularly suitable for industries such as power and chemical industry that require high production continuity, effectively reducing downtime losses caused by equipment failures.

3. Strong scalability and compatibility, flexible adaptation

As the core of the AC 800M control system, PM645B is seamlessly compatible with ABB's full range of I/O modules, such as digital input module DI810, digital output module DO810, analog input module AI810, etc. It can connect up to 8 expansion units through an expansion rack, meeting the I/O scale requirements from tens to thousands of points. Simultaneously supporting multiple industrial communication protocols, including PROFINET, Modbus TCP, EtherNet/IP, etc., it can easily exchange data with field instruments, actuators, frequency converters, and upper monitoring systems, facilitating the construction of an integrated industrial automation control network and reducing system integration difficulty.

4. Convenient programming and debugging to improve development efficiency

The module supports five programming languages specified in the IEC 61131-3 standard. Engineers can choose familiar languages such as ladder diagram (LD), functional block diagram (FBD), structured text (ST), etc. for program development based on control requirements, reducing learning and development costs. Combined with ABB's dedicated Control Builder M programming software, control program writing, downloading, online monitoring, and debugging can be achieved. The software has a rich library of functional blocks (such as PID control blocks, interlock control blocks, etc.) built-in, eliminating the need for repeated development of basic functions and greatly improving programming efficiency. Simultaneously supporting online modification of programs and parameters, debugging and optimization can be completed without downtime, reducing production interruption time.

5. Improve diagnostic and maintenance functions to reduce operation and maintenance costs

PM645B has comprehensive self diagnosis and fault alarm functions, which can monitor the real-time operation status of the module itself (such as power supply, memory, communication, etc.) and the status of the connected I/O modules. When a fault occurs, it can provide timely feedback on the fault location and type through indicator lights, software alarms, etc., making it easy for operation and maintenance personnel to quickly locate and troubleshoot the problem. In addition, the module supports fault logging function, which can store historical fault information, provide data support for fault analysis and preventive maintenance, reduce operation and maintenance difficulty and cost, and improve equipment management efficiency.

Applicable scenarios

-Chemical process control: used for reaction process control, material ratio control, pressure and temperature regulation of chemical production equipment, achieving precise control of complex process parameters, ensuring production safety and product quality.

-Power system control: adapted to the auxiliary system control of thermal power plants and hydropower stations (such as water pump and fan control) and the automation control of substations, to achieve equipment start stop interlocking, operation parameter monitoring and adjustment.

-Metallurgical industry control: used for controlling smelting, rolling, heat treatment and other processes in the production of steel and non-ferrous metals, achieving real-time adjustment of parameters such as temperature, pressure, flow rate, etc., and improving production efficiency.

-Water treatment system: applied to the process control of water treatment plants and sewage treatment plants, such as dosing control, sedimentation filtration control, water quality monitoring, etc., to ensure the water treatment effect and standard discharge.

-Paper and printing industry: used for controlling the thickness and humidity of paper in paper production lines, as well as controlling the printing accuracy during the printing process, to improve product quality stability.

-Large scale manufacturing production lines: adapted to the automation control of production lines in industries such as automobiles and machinery manufacturing, achieving equipment linkage, process coordination, and production process optimization.

Installation and usage precautions

1. Installation specifications

-The module should be installed in an industrial control cabinet that meets the protection level of IP54 or above, avoiding environments with dust, moisture, corrosive gases, and severe vibrations. The installation location should be away from strong electromagnetic interference sources (such as frequency converters and high-power motors).

-During installation, it is necessary to follow the rack installation requirements of the AC 800M system, smoothly insert the module into the rack rail and lock it to ensure good contact between the module and the rack bus, and avoid communication failures caused by poor contact.

-The power wiring should strictly distinguish between positive and negative poles to ensure that the input voltage is DC 24V ± 10%. After the wiring is completed, the firmness of the wiring should be checked to prevent loosening and power failure.

-Communication cables should use shielded wires and be laid separately from power cables (with a spacing of not less than 30cm) to reduce electromagnetic interference. Both ends of the cable should be reliably grounded.

2. Debugging and maintenance

-Before the first debugging, it is necessary to configure the module parameters through Control Builder M software, including communication address, control cycle, redundancy settings, etc., to ensure that the configuration parameters are consistent with the system requirements.

-Before downloading the program, it is necessary to check whether the communication connection between the module and the computer is normal. During the download process, avoid interrupting communication to prevent program damage from causing the module to fail to start properly.

-During daily maintenance, it is necessary to regularly check the status of module indicator lights (power light, running light, fault light), monitor module operating parameters (such as CPU usage and memory usage) through software, and promptly detect abnormal situations.

-Regularly (recommended every six months) carry out dust removal treatment on the control cabinet to maintain good module heat dissipation and avoid excessive temperature caused by dust accumulation affecting module performance.

-For systems with redundant configurations, it is necessary to regularly test the redundancy switching function to ensure that it can switch normally in the event of a failure. Before testing, a production emergency plan must be prepared.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-