Kollmorgen RCS2 - Painting Pump and Servo Motor

The Kollmorgen RCS2 stands out as a premier motion control solution tailored for demanding environments in the power industry, petrochemical sectors, and general automation applications. Engineered for robust performance, the RCS2 delivers exceptional reliability, precision, and scalability, making it a preferred choice for operations where uptime and accuracy are critical. At its core, the Kollmorgen RCS2 features an advanced input/output architecture capable of handling extensive signal processing demands. With multi-axis control capabilities, it supports high-speed synchronization and real-time data throughput, ensuring seamless integration with complex automation systems. The device’s input/output capacity is designed for flexibility, managing up to 32 digital inputs and 32 digital outputs, alongside multiple analog channels, which provide granular control and monitoring for diverse industrial processes. Durability is a hallmark of the RCS2, constructed to withstand harsh environmental conditions typical in petrochemical plants and power generation facilities. Its rugged enclosure meets stringent industrial standards for shock, vibration, and temperature resistance, guaranteeing reliable operation even under the most challenging conditions.

Performance-wise, the Kollmorgen RCS2 is optimized for fast response times and high-precision motion control, supporting closed-loop servo feedback and advanced trajectory planning. It excels in applications requiring synchronized multi-axis control, such as turbine regulation in power plants or robotic automation within petrochemical processing lines. The unit’s real-time control algorithms reduce latency, improving overall system efficiency and throughput. Additionally, the RCS2’s modular design allows for easy scalability and customization, which is essential for evolving automation needs. In real-world scenarios, the application of RCS2 in the power industry is profound. It effectively manages generator synchronization, load sharing, and dynamic response to grid changes, ensuring stability and efficiency. In the petrochemical sector, the RCS2 facilitates precise control of pumps, valves, and mixers, enhancing process safety and throughput. Its adaptability also makes it ideal for general automation tasks such as conveyor belt coordination, assembly line robotics, and packaging machinery, where consistent accuracy and uptime are imperative. When comparing the Kollmorgen RCS2 to other models within the Kollmorgen portfolio, its unique advantages become clear.

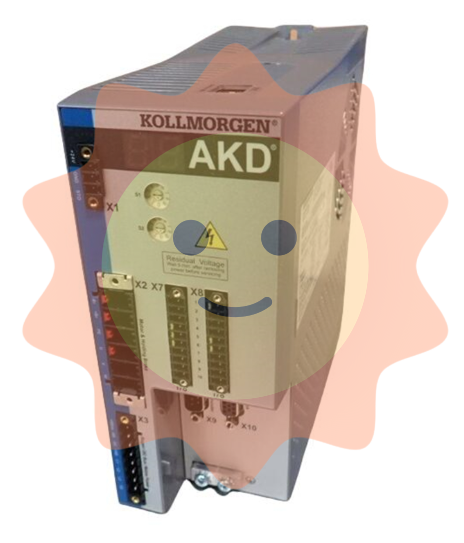

For instance, while the Kollmorgen M.3000.1408 and M.1016.2540 offer solid performance in servo drives and motion control, the RCS2 provides enhanced I/O capabilities and real-time processing power, making it superior for multi-axis, high-demand applications. Similarly, the Kollmorgen AKM22E-VBBNR-00 and AKM65S-ANR2MA02 motors are excellent for actuation, but when paired with the RCS2 controller, they unlock advanced system-level performance with precise feedback and control. The Kollmorgen PSR4/5A-220 and PSR3-230/75-21-202 power supplies complement the RCS2 by providing reliable power conditioning, ensuring uninterrupted operation in critical environments. Alongside the Kollmorgen RCS2, other products such as the Kollmorgen DMC250720P motion controller, Kollmorgen S30361-MN encoder, and Kollmorgen IL18100A3TRC1 interface modules offer complementary functionality that enhances system integration and performance. The Kollmorgen M21NRXB-LSN-NS-04 and SR20200-00000 servo amplifiers further extend the control ecosystem, providing precise torque and speed regulation when combined with the RCS2 controller. For applications requiring advanced feedback and safety features, the Kollmorgen BDS3-208/12-01-200-2102A14 and BDS5A-220-00010-606A-2-031 series bring redundant safety and diagnostic capabilities, making them ideal partners for the RCS2 in mission-critical automation setups.

In summary, the Kollmorgen RCS2 is a robust, high-performance motion control solution designed to meet the rigorous demands of the power industry, petrochemical plants, and general automation sectors. Its superior input/output capacity, durability, and advanced control algorithms set it apart within the Kollmorgen automation products lineup. By integrating with related models like the Kollmorgen M.3000.1408, AKM22E-VBBNR-00, PSR4/5A-220, and DMC250720P, users can build comprehensive, scalable automation systems that maximize efficiency, safety, and reliability. Whether synchronizing generators, regulating chemical processing equipment, or automating complex manufacturing lines, the Kollmorgen RCS2 offers unmatched precision and dependability, making it a cornerstone in modern industrial automation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-